Constant-tension sheet storage device

A technology of constant tension and film storage, which is applied in the directions of transportation and packaging, winding strips, and function indication, can solve the problems of irradiated product range affecting product quality, irradiated product tension control, etc., and achieve constant tension control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

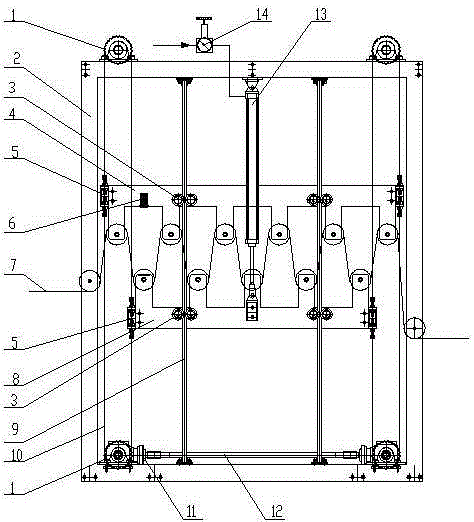

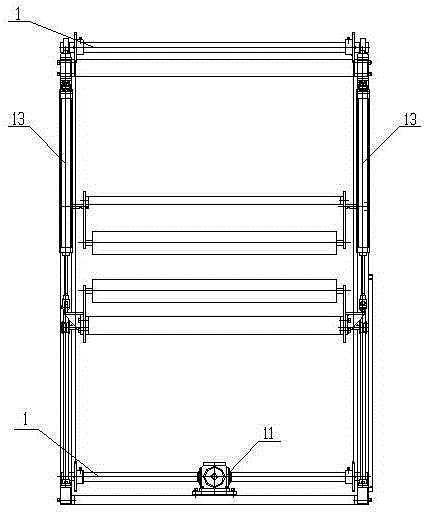

[0017] Such as figure 1 with figure 2 As shown, a constant tension film storage device includes a frame 2. Both upper and lower ends of the frame 2 are provided with synchronous sprocket shafts 1, and both ends of the upper synchronization sprocket shaft 1 and the lower synchronization sprocket shaft 1 Synchronous chains 10 are correspondingly connected between the two ends of the frame 2. The frame 2 is also equipped with an upper sliding roller group 4 and a lower sliding roller group 8 through four synchronous chains 10, and the upper and lower sliding roller groups are provided with a plurality of The guide wheels 15 and the upper and lower groups of guide wheels 15 are arranged crosswise, the sheet 7 sequentially bypasses the guide wheels 15 and the upper and lower sliding roller groups can move relative to or backward with the forward and rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com