A spiral lifting mechanism and an agv trolley

A lifting mechanism and jacking mechanism technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of unaffordable logistics industry, high labor cost, and no ability to sneak in to lift and transport goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

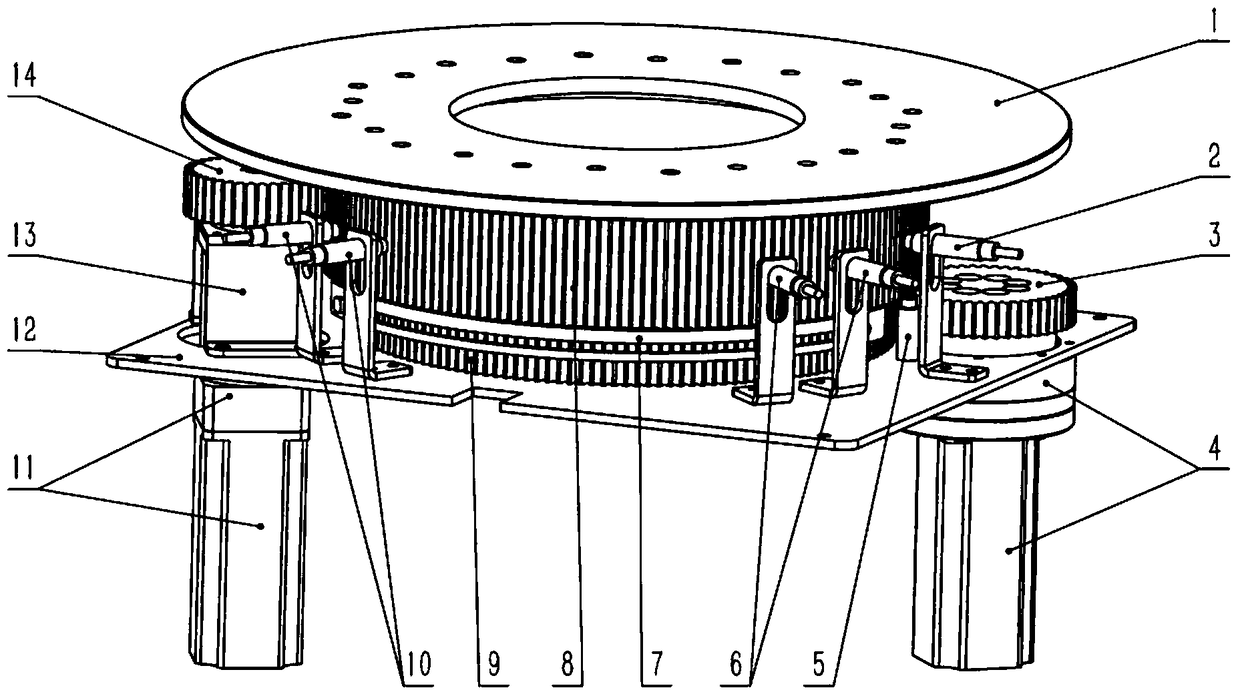

[0022] Such as figure 1 , 2 As shown, the screw lifting mechanism of the present invention includes a jacking plate 1, an installation base plate 12, a jacking mechanism and a jacking drive mechanism;

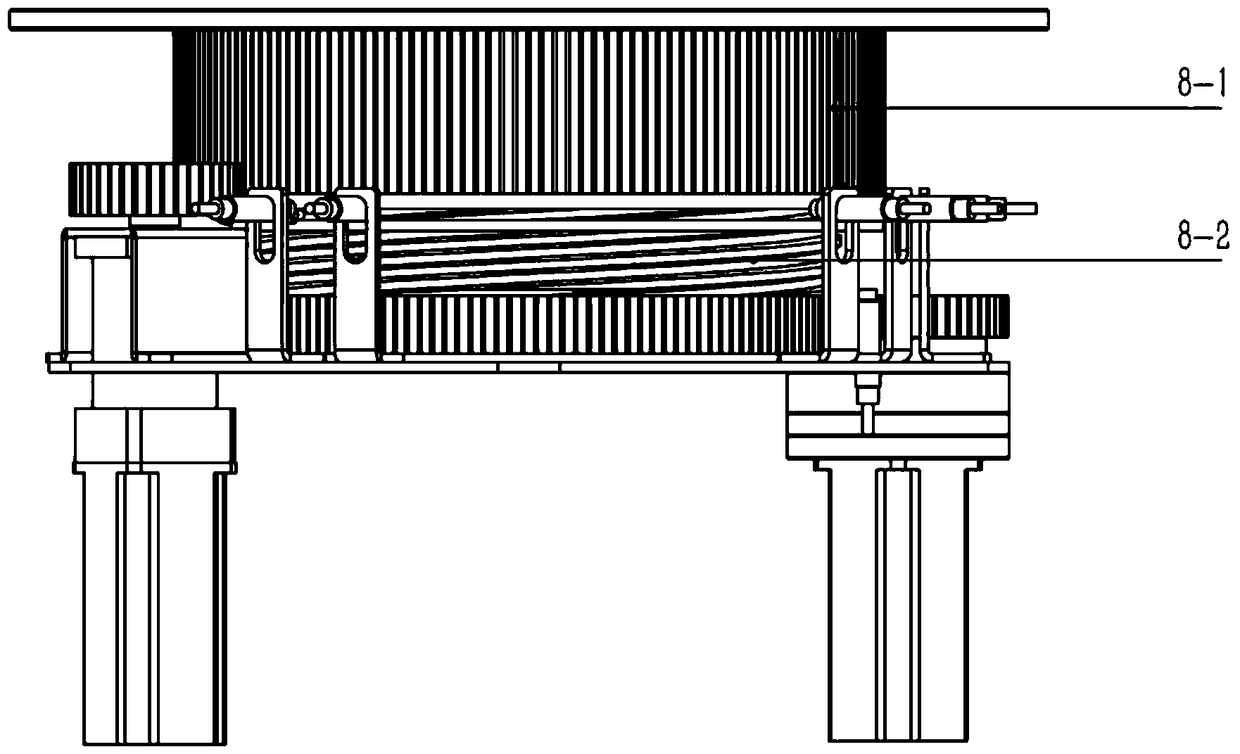

[0023] The jacking mechanism includes a threaded pair 8 and a slewing bearing 9; the external threaded part 8-1 of the threaded pair 8 is a part whose outer ring is a gear and the inner ring is a threaded part, and the internal threaded part 8-2 of the threaded pair 8 is The outer ring is a threaded part, and the inner thread of the outer threaded part 8-1 engages with the outer thread of the inner threaded part 8-2; the center of the thread pair 8 can be a hollow structure, and a camera and other equipment can be installed in the hollow structure , to facilitate scanning the identification code on the bottom of the goods on the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com