Glass laminating machine for producing vacuum laminated glass

A technology of laminating machine and vacuum clamping, applied in the field of glass laminating machine, can solve the problems of low production efficiency of glass laminating machine, difficult to maintain constant temperature, unbalanced heating of glass, etc., to reduce heat loss, easy to operate, The effect of tight and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

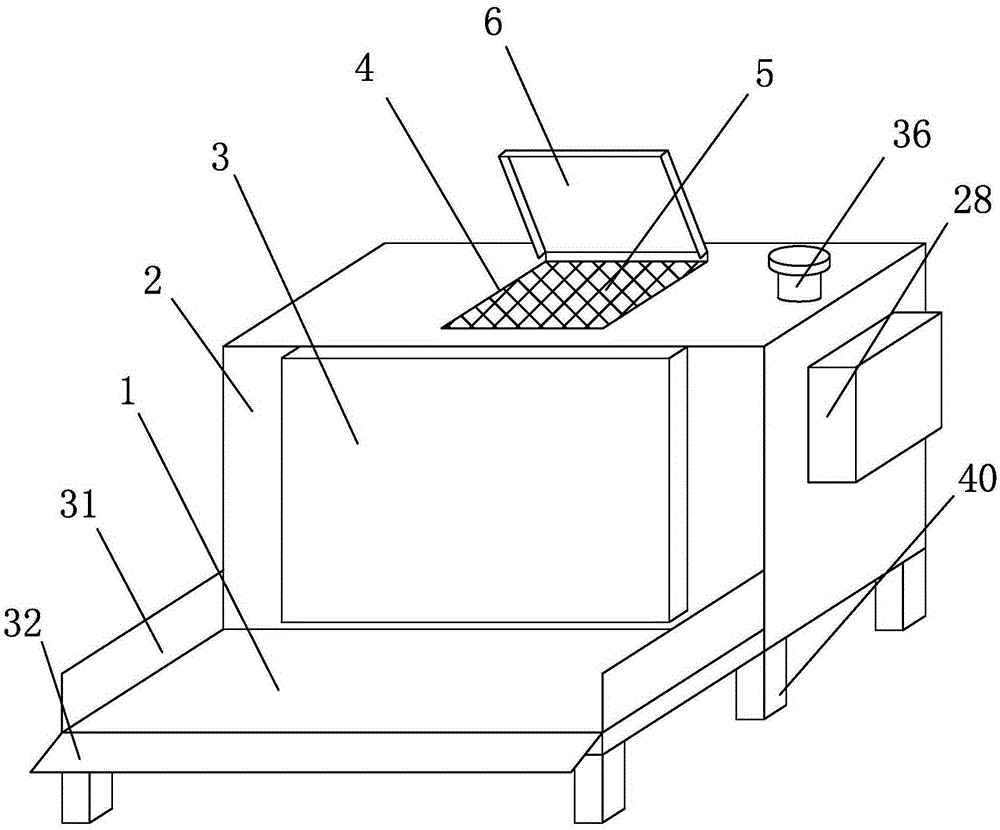

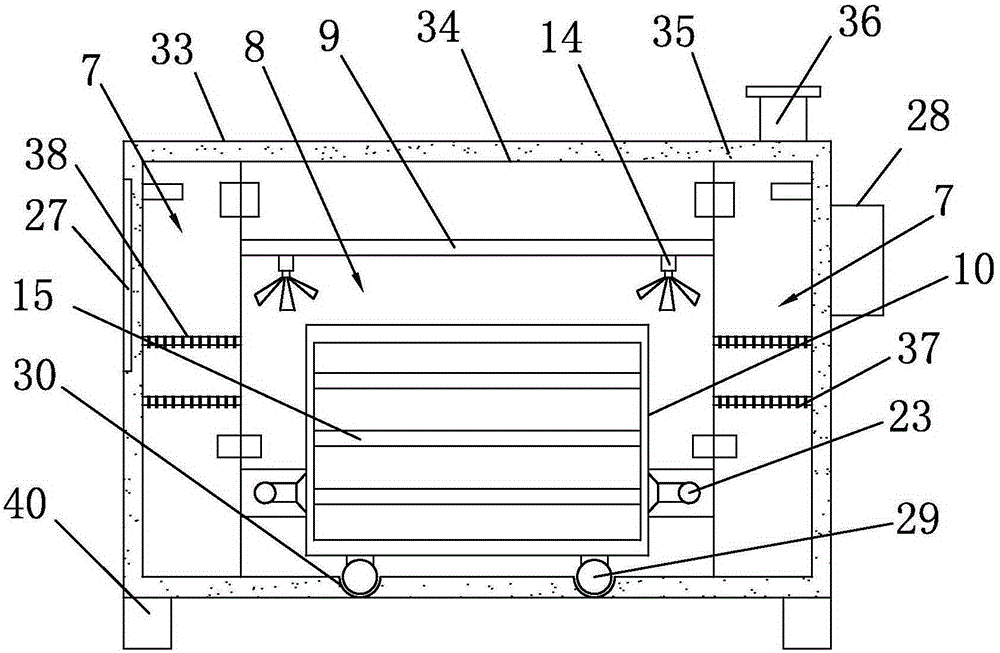

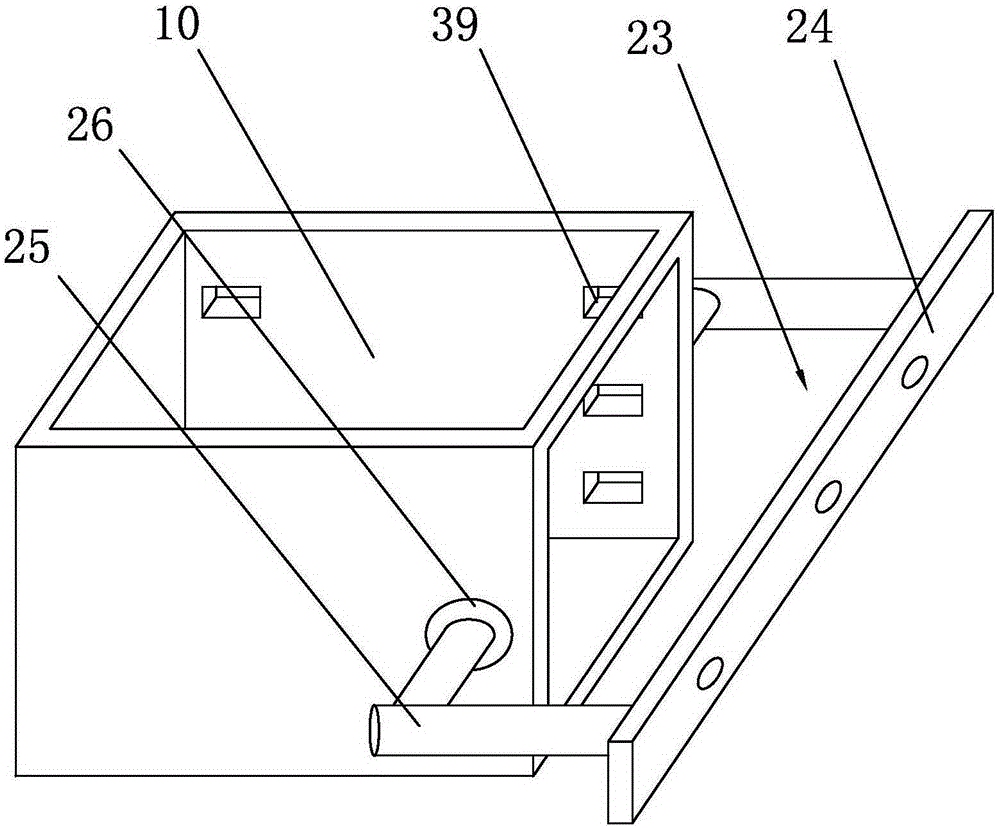

[0032] Such as Figure 1 to Figure 6 As shown, it is a glass lamination machine for producing vacuum laminated glass according to the present invention, which includes a cooling table 1 and a cabinet 2. A lifting door 3 is arranged on the front end of the cabinet 2, and the cooling table 1 can improve the glass lamination machine. The safety performance reduces the incidence of accidents. When the glass heating is completed, the glass bracket 10 can be pushed onto the cooling table 1 for cooling again to prevent the operator from being scalded by residual heat. The cooling table 1 is located on the left side of the chassis 2 Side, both sides of the cooling table 1 are provided with fixed baffles 31, and the front face of the cooling table 1 is provided with a movable baffle 32, the design of the fixed baffle 31 can prevent the glass holder 10 from being placed on the cooling table 1. Move, cause safety accident, movable baffle 32 realizes moving and fixing of glass bracket 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com