Method for conducting rail-mounted type automatic slag discharging on gasification furnace

An automatic unloading and gasification furnace technology, which is applied in the fields of automatic ash unloading, transportation, and slag discharge of gasifiers, can solve the problems of difficult dust sealing, low automation level, and high failure rate of belt conveyors to meet the requirements of automatic production required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

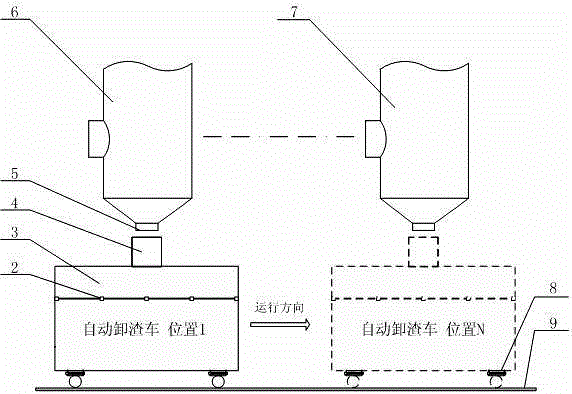

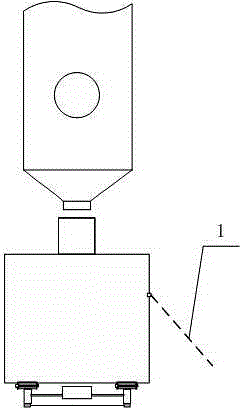

[0015] Attached below figure 1 , 2 The present invention is described in further detail.

[0016] A track-type automatic slag unloading method for a gasifier. The automatic slag unloading vehicle automatically unloads the gasifier, and a fixed track is set on the ground below the gasifier. The automatic slag unloading vehicle walks on the fixed track, When it is necessary to discharge ash and slag, the automatic slag unloading vehicle automatically moves along the track to the bottom of the gasifier that needs to unload slag according to the slag unloading request signal, and the slag receiving device on the automatic slag unloading vehicle automatically aligns with the lower ash valve of the gasifier to close it Type slag unloading operation, after the gasifier completes slag unloading, the automatic slag unloading vehicle moves along the track to the fixed slag discharge point according to the instructions, and automatically opens the slag opening door to discharge the ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com