Intelligent warehousing method and transfer system

An intelligent warehousing and chain conveyor technology, applied in the directions of transportation and packaging, packaging/bundling items, labels, etc., can solve the problems of unable to control a fixed quantity of materials, unable to adjust the stack of products regularly, and no packaging and fixing, etc. The effect of improving packaging efficiency and reliability, reducing labor intensity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

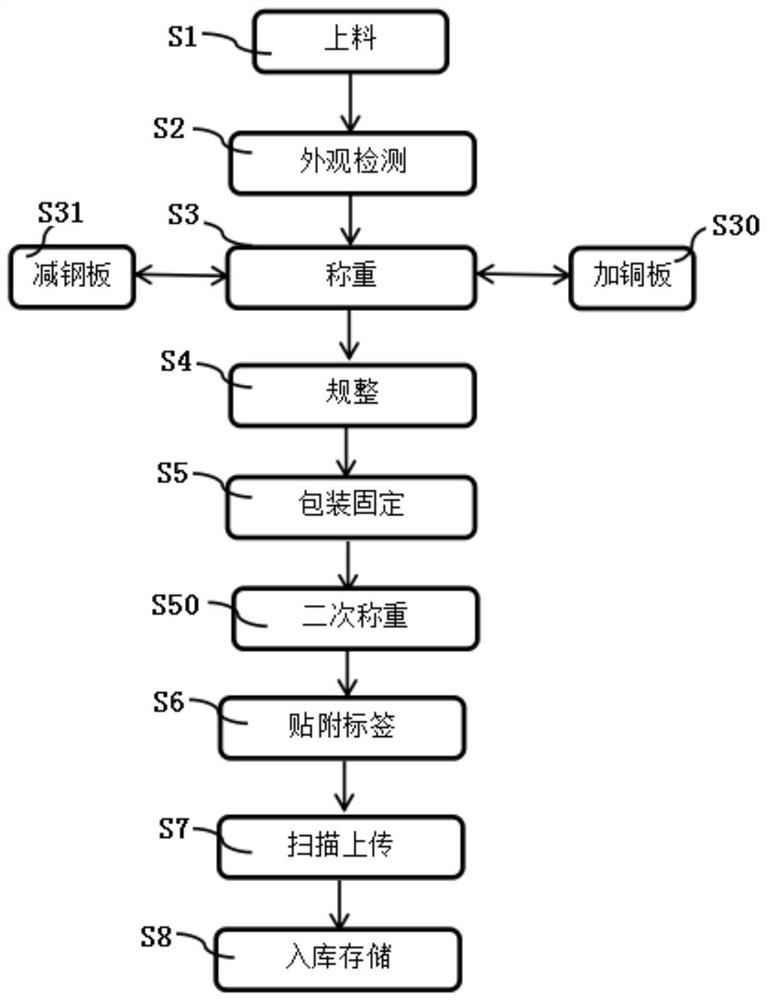

[0078] Such as figure 1 As shown, an intelligent warehousing method is provided, including the following steps:

[0079] S1: Loading; receiving and transmitting the stacked cathode copper stacks;

[0080] S2: Appearance inspection, conduct appearance inspection on incoming materials, pick out defective products, qualified products and enter the next step;

[0081] S3: Weighing, weighing the total weight after stacking, to ensure that the total weight of each cathode copper stack is within a fixed range;

[0082] S4: Neatness; regularize the cathode copper stack, so that each cathode copper plate in the cathode copper stack is neatly stacked;

[0083] S5: Packaging and fixing; packaging and fixing the regularized cathode copper stacks, so that the relative displacement of each cathode copper plate in the cathode copper stacks will not occur.

[0084] S6: Labels are attached; labels are attached to each stack of copper cathodes, and the labels include production information s...

Embodiment 2

[0088] Embodiment two: the difference of embodiment two is that step S3 is further optimized, specifically:

[0089] When weighing, if the total mass of the cathode copper stack is lower than the set value, copper plates are added on the copper stack; if the total mass of the cathode copper stack is higher than the set value, the copper plates on the copper stack are removed. According to the weight data after weighing, it is judged whether the weight of the cathode copper stack should be added or subtracted, and the weight of the cathode copper stack is controlled at 2.5 tons, and the error is controlled within ±50kG.

Embodiment 3

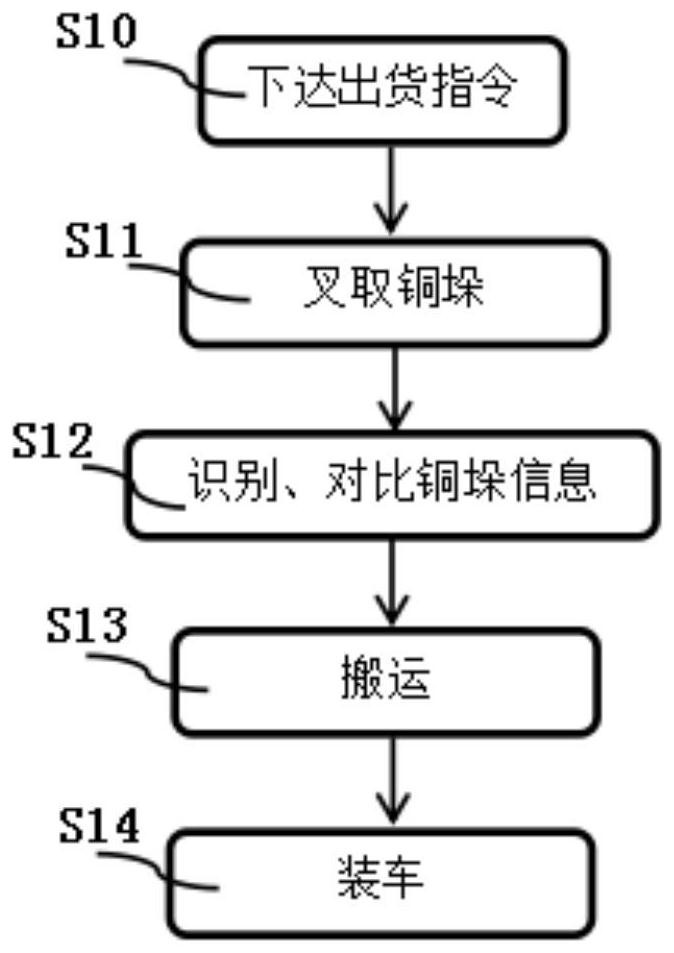

[0090] Embodiment three: as figure 2 As shown, the difference between the third embodiment is that the third embodiment discloses a warehouse-out method, which specifically includes:

[0091] S10: issue a shipping order;

[0092] S11: The stacker picks up the copper stack on the designated location according to the shipping instruction;

[0093] S12: Label identification; the stacker scans and identifies the labels, and feeds the identification information back to the background server, and the server determines whether the information on the copper stack is consistent with the information in the system;

[0094] If yes, proceed to the next step;

[0095] If not, put the copper stack back and fork the goods again;

[0096] S13: Handling; transfer the copper stack from the stacker to the area to be loaded;

[0097] S14: loading out of the warehouse; the copper stacks are loaded into the vehicle, and the vehicle leaves the site after the loading is completed.

[0098] Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com