A method and device for electrolytic flue gas purification without power injection feeding

A feeding device and flue gas purification technology, which is applied in the field of harmful flue gas purification, can solve the problems of increased energy consumption of electrolytic aluminum, increased energy consumption of the system, and increased noise sources of the purification system, so as to reduce energy consumption and cost, and reduce pollutants. The effect of emission, efficient and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

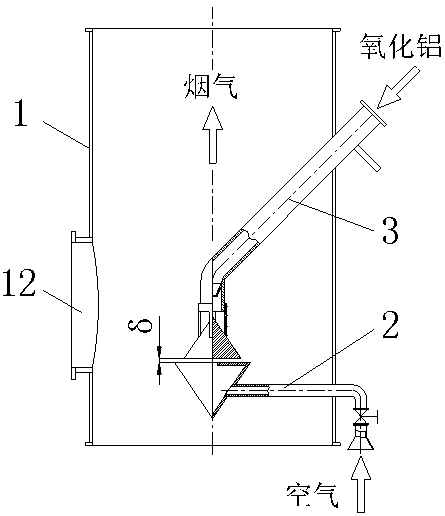

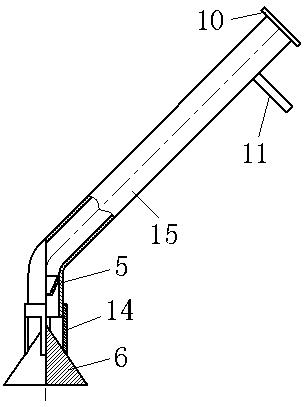

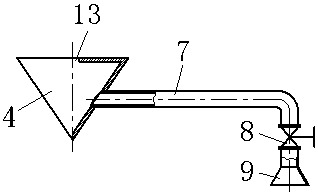

[0025] The method in this example is as Figure 1-3As shown, a reactor cylinder 1 is installed on the vertical vertical pipe of the dust collector inlet of the flue gas purification system, and the flue gas enters the reactor cylinder 1 from bottom to top; Blowing device 2 and feeding device 3; alumina enters the reactor barrel 1 through the feeding chute 15 on the feeding device 3. Since the injection blowing device 2 and the feeding device 3 in the reactor cylinder 1 are set separately, the space in the feeding chute 15 is large and not easy to be blocked, and the feeding chute 15 is arranged obliquely, and the alumina falls in the feeding chute by its own gravity , the alumina flow rate is slow, it will not cause strong wear to the equipment, and it is not easy to block the feeding channel due to alumina damage and "slag shell"; in this example, the shape of the nozzle 4 in the injection injection device 2 is an inverted conical shape , which is beneficial to play a turbul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com