Automatic cloth washing-alkali cooking device and automatic cloth washing-alkali cooking method

A technology of washing cloth and boiling alkali, applied in the field of dyeing, can solve the problems of skin damage, long cleaning time, color difference of color samples, etc., and achieve the effect of preventing damage and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

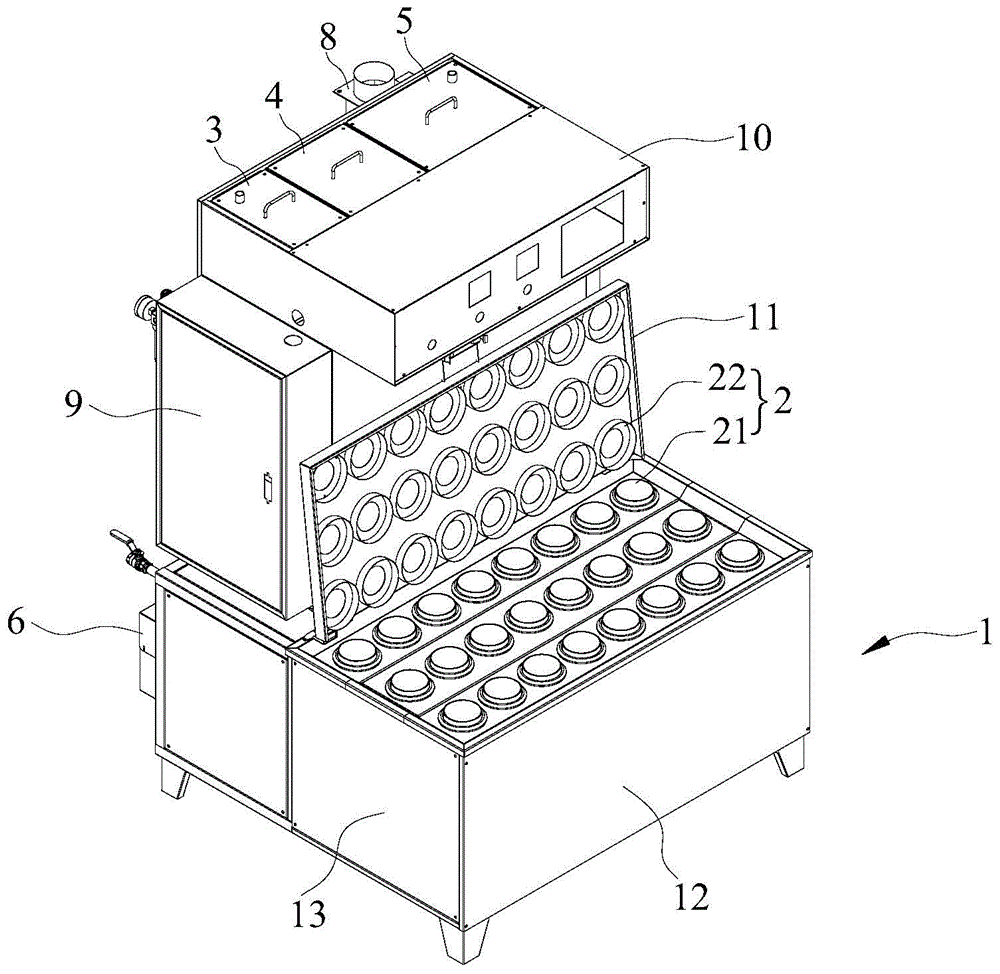

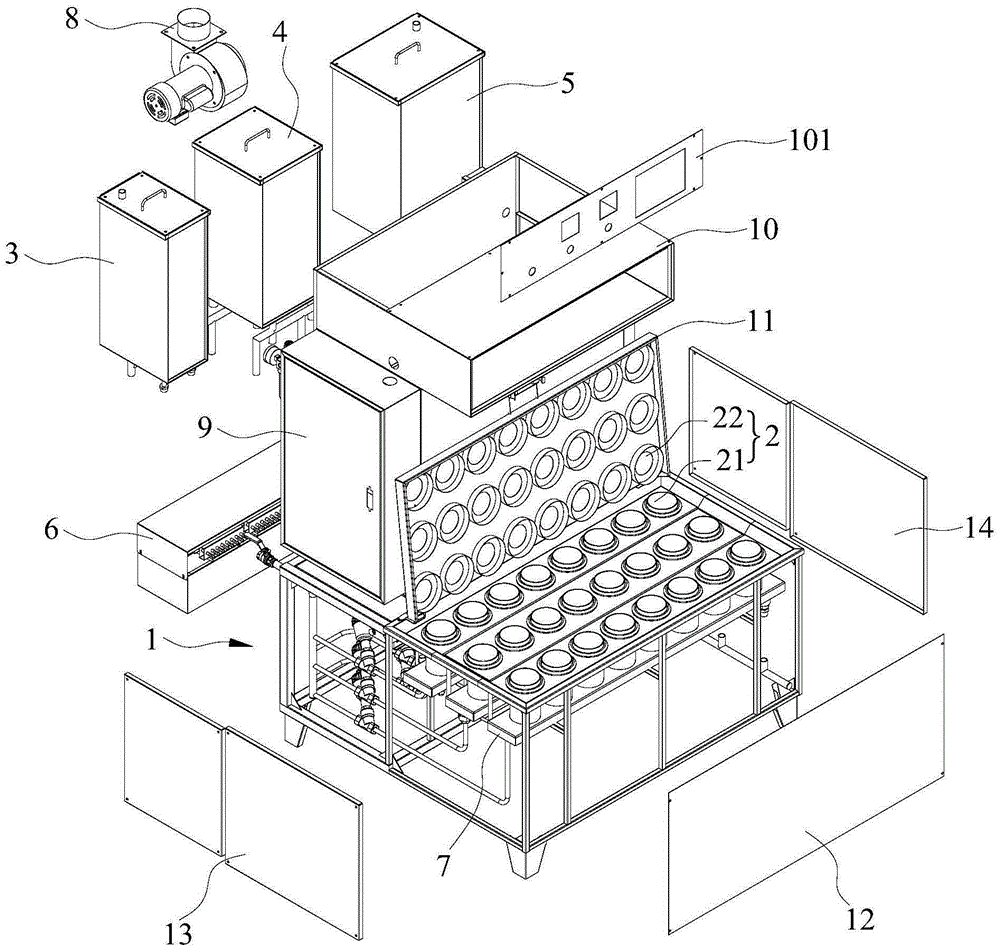

[0034] Combine below Figure 1~3 And further illustrate the technical solution of the present invention through specific examples.

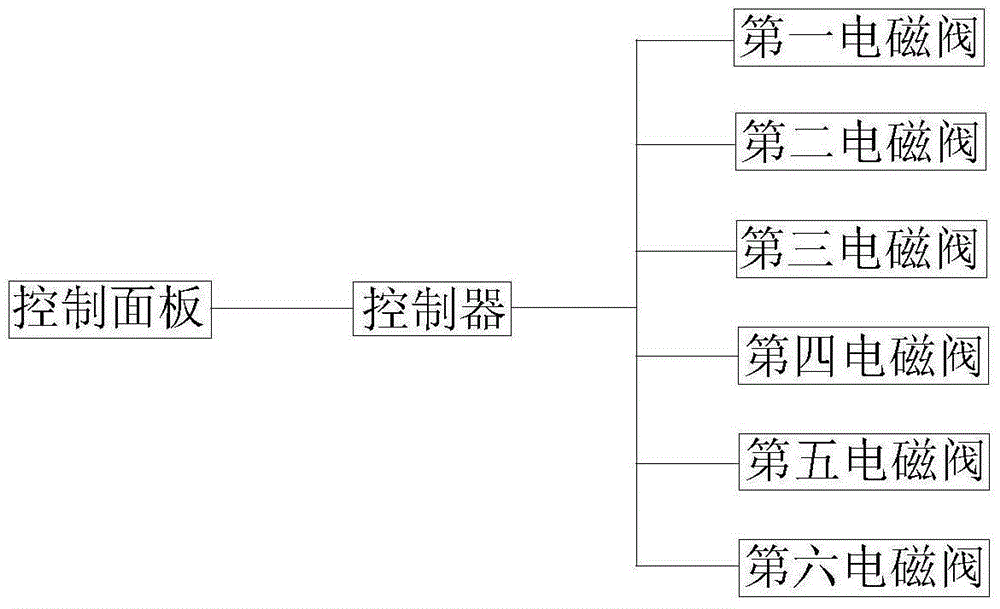

[0035] Such as Figure 1~2 As shown, the automatic cloth washing-soda boiling device of the present embodiment comprises a frame and a cup 2 arranged on the frame 1, and the cup 2 communicates with the water tank 3, the glacial acetic acid tank 4, the alkali oil tank 5, and the drainage tank 6 through pipelines respectively. Connected setting, the cup 2 is also connected with the stirring device and the heating device respectively, the pipeline between the cup 2 and the water tank 3, the pipeline between the cup 2 and the glacial acetic acid tank 4, the pipeline between the cup 2 and the alkali oil tank 5 And the pipeline between the cup 2 and the drainage tank 6 is provided with a solenoid valve, and the solenoid valve, stirring device and heating device are all connected with the controller. In the automatic cloth washing-soda boiling device ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap