Prefabricated continuous wall unit, underground continuous wall and construction method of underground continuous wall

A technology for underground diaphragm walls and connecting steel plates, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problem of difficulty in ensuring the strength and anti-seepage performance of underground diaphragm walls and joints, inability to ensure the support effect of foundation pit engineering, cross One side of the shaped steel plate is not stable, etc., to achieve the effect of enhancing rigidity, shortening the construction period, and reducing the impact of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

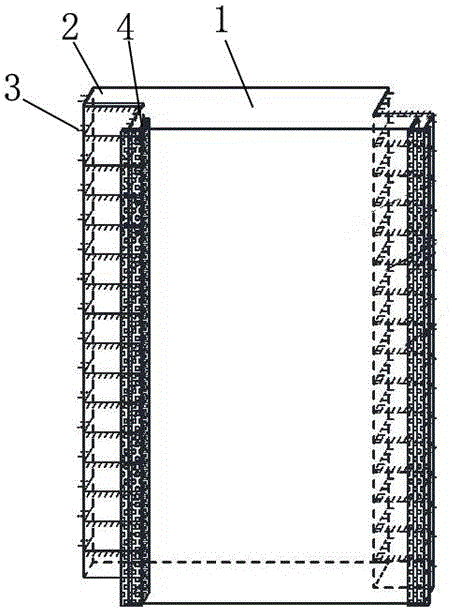

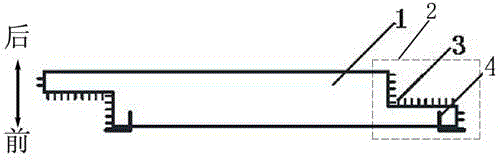

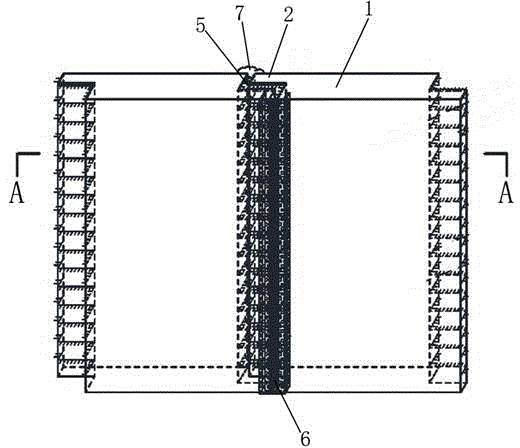

[0025] Such as figure 1 , figure 2 As shown, a prefabricated continuous wall unit includes a prefabricated continuous wall unit body 1, the thickness of the prefabricated continuous wall unit body 1 is 800mm~1200mm, and the two ends of the prefabricated continuous wall unit body 1 are provided with stepped joints 2, The joint 2 is symmetrically arranged centering on the center of the cross section of the prefabricated continuous wall unit body 1, and the surface of the joint 2 is roughened; the prefabricated continuous wall unit body 1 is provided with a steel bar 3 protruding from the surface of the joint 2, so that The steel bars 3 are HRB400 threaded steel bars, the length of one end of the steel bars 3 protruding from the surface of the joint 2 is 100mm~150mm, the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com