Hole digging machine with damping blocks and water collection hole

A technology of water collecting holes and shock-absorbing blocks, which is applied in the direction of earth movers/shovels, construction, etc., can solve the problem of increasing equipment costs and use costs, difficult to adapt to construction conditions and requirements, and not well suited for digging holes Operation and other problems, to achieve the effect of increasing flexibility, increasing diameter, and reducing thread lift angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

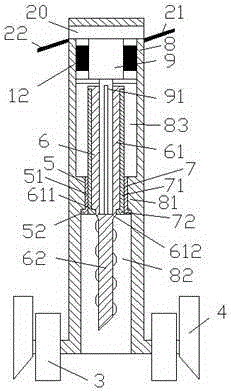

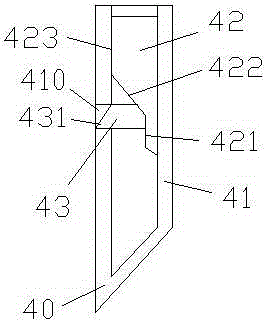

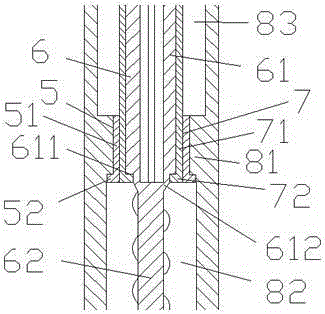

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] The hole digging machine with a shock absorber and a water collection hole according to an embodiment includes an outer casing 8, a drive motor 9 and a hole-digging drill rod part 6 driven by the drive motor 9, wherein the drive motor 9 is set In the outer casing 8, a water collecting hole 20 is arranged laterally in the outer casing 8 above the driving motor 9, and a water inlet deflector 21 is arranged obliquely at the bottom of the right side of the water collecting hole 20. The bottom left side of the water hole 20 is obliquely provided with a water outlet deflector 21, and the water inlet deflector 21 and the water outlet deflector 21 are arranged parallel to each other to collect rainwater through the water inlet deflector 21 when it rains. The water collecting hole 20 then flows out from the water outlet deflector 21 so as to take away the heat dissipated by the driving motor 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com