Method and device for on-line measurement of water content in oil well single well crude oil by gas-liquid separation

A gas-liquid separation device and gas-liquid separation technology, applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of gas-liquid separation, measurement accuracy, influence, and large gas volume of oil wells, and achieve light weight, The effect of accurate measurement and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

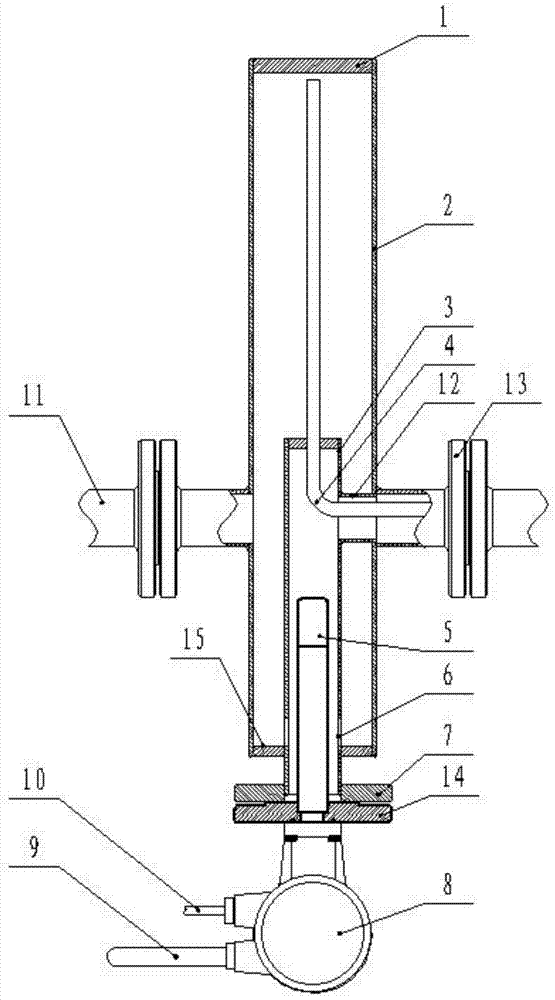

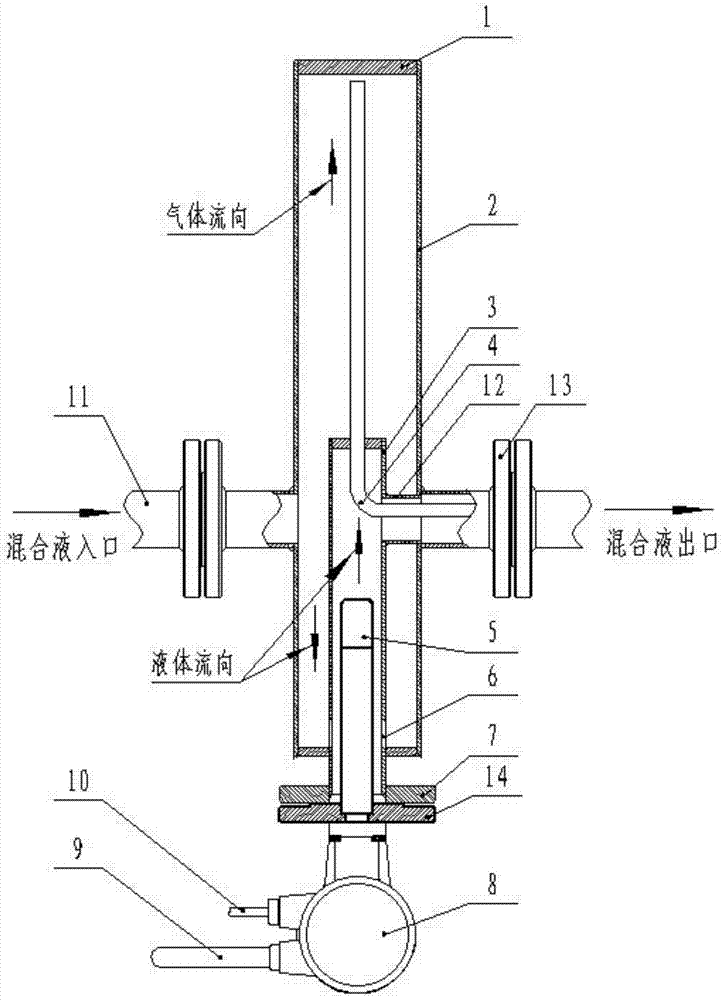

[0030] Such as Figure 1 ~ Figure 2 As shown, the present invention includes a radio frequency moisture analyzer 8 on which a signal cable 10 , a wireless transmission module 9 and a probe 5 are arranged. A gas-liquid separation device is set on the radio frequency moisture analyzer 8; the gas-liquid separation device includes a closed outer tube 2 and an inner tube 3 made of a body, an upper end plate 1 and a lower end plate 15; two upper tubes on the outer tube 2 side opening, the outer pipe 2 communicates with the mixed liquid inlet of the wellhead pipeline 11 through the opening on one side and the shorting flange 13, and the inner pipe 3 communicates with the opening on the other side of the outer pipe 2 through the pipe section 12 and passes through the side opening The hole, the shorting flange 13 and the mixed liquid outlet of the wellhead pipeline 11 communicate. The lower end of the inner pipe 3 is closed and protrudes outside the outer pipe 2 as the installation en...

Embodiment 2

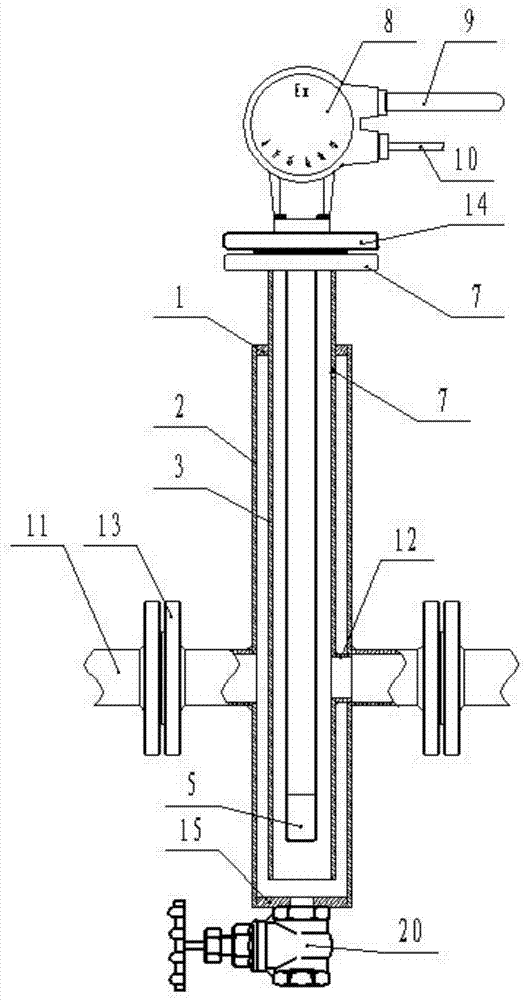

[0033] Such as Figure 3 ~ Figure 4 As shown, the present invention has a radio frequency moisture analyzer 8 on which a signal cable 10 , a wireless transmission module 9 and a probe 5 are arranged. A gas-liquid separation device is set on the radio frequency moisture analyzer 8; the gas-liquid separation device includes a closed outer tube 2 and an inner tube 3 made of a body, an upper end plate 1 and a lower end plate 15; two upper tubes on the outer tube 2 Side openings form a mixed solution inlet and a mixed solution outlet, the mixed solution inlet communicates with the outer tube 2, the mixed solution outlet communicates with the inner tube 3 through a pipe section 12, and the mixed solution inlet and the mixed solution outlet are connected by a short connection method The flange 13 is connected to the wellhead pipeline 11, the upper end of the inner pipe 3 is closed and protrudes outside the outer pipe 2 as the installation end, and the installation end is fixed with a...

Embodiment 3

[0036] Such as Figure 5 ~ Figure 6Shown, the present invention comprises radio frequency moisture analyzer 8, is provided with signal cable 10, wireless transmission module and probe 5 on radio frequency moisture analyzer 8, is provided with gas-liquid separation device on radio frequency moisture analyzer 8, and described gas-liquid separation The device includes a closed outer tube 2 and an inner tube 3 composed of a tube body, an upper end plate 1 and a lower end plate 15. The upper end of the tube body is fixed with an annular support 16, and the upper end plate 1 is installed on the ring by fastening screws. A detachable structure is formed on the support 16, and the radio frequency water content analyzer 8 is arranged on the upper end plate 1 of the outer pipe; The other two ports of the tee are respectively connected to the mixed liquid inlet and the mixed liquid outlet of the wellhead pipeline 11. The lower end of the inner pipe 3 is a gas-liquid discharge pipe 19, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com