Adjustment device for a hydrostatic piston machine, and hydrostatic axial piston machine

A technology of axial piston machine and adjusting device, which is applied in the direction of fluid pressure actuating device, machine/engine, liquid variable capacity machine, etc., can solve the problems of large structural length and complex structure of adjusting device, etc. The effect of low equipment technical expenses and increased work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

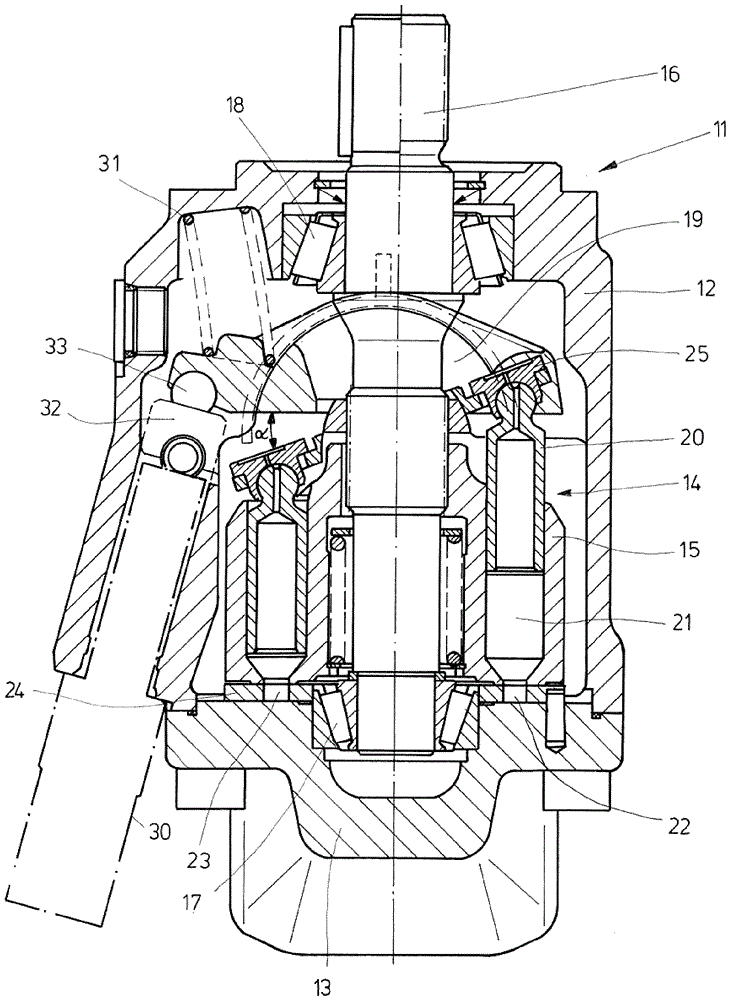

[0037] figure 1 The hydrostatic axial piston machine shown in is designed as an axial piston pump. The hydrostatic axial piston machine has a pump housing 11 , which is formed from a basin-shaped housing main part 12 and a connecting plate 13 , and in which a transmission 14 is accommodated. Belonging to this transmission are a cylindrical drum 15, a transmission shaft 16 and a pivoting cradle 19 adjustable in its angular position relative to the axis of the transmission shaft, which is supported by two tapered roller bearings 17 and 18 on The pump housing, and the cylindrical drum 15 is anti-rotationally coupled with the drive shaft. In the cylindrical drum 15 a plurality of plungers 20 are guided parallel to the axis of the drive shaft, said plungers each delimiting a working chamber 21 . The supply and discharge of pressure medium to the working chamber 21 is controlled via two control junctions 22 and 23 which are formed in a control plate 24 held in a rotationally fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com