Combustion chamber of supersonic combustion ramjet engine

A technology of super-combustion stamping and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., and can solve the problems of unfavorable cavity ignition and stable combustion, large total pressure loss of multi-cavity, and oil-rich ignition of cavity , to achieve the effects of improving flame stability, optimizing fuel equivalence ratio distribution, and improving ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

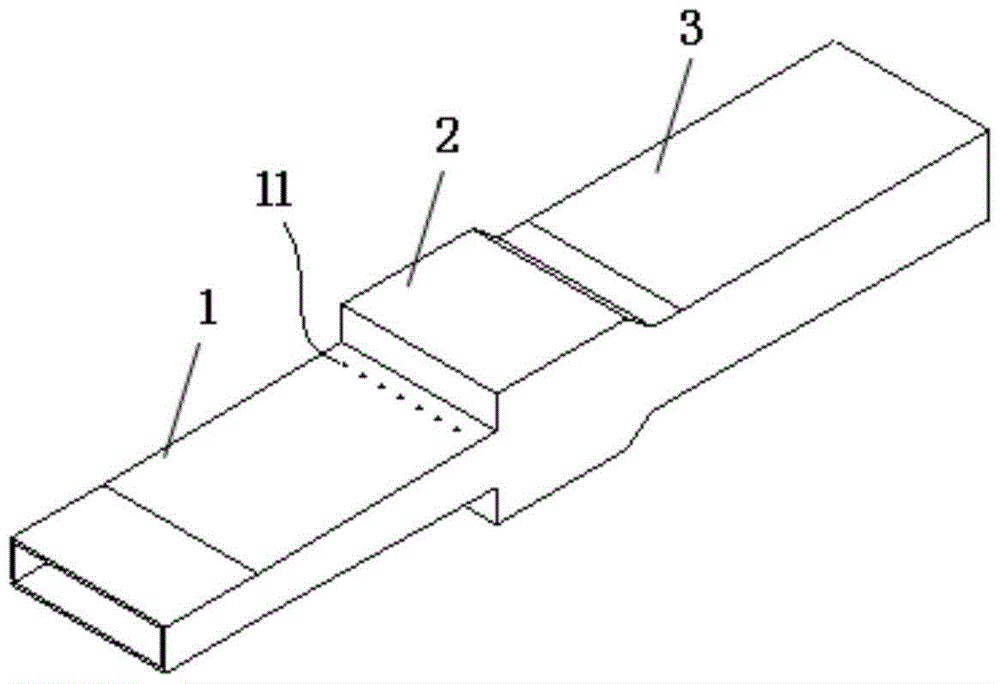

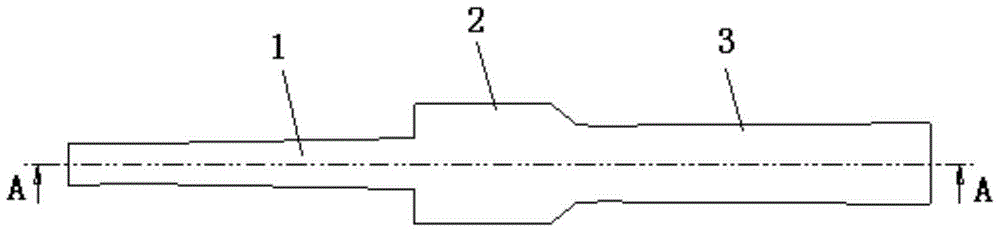

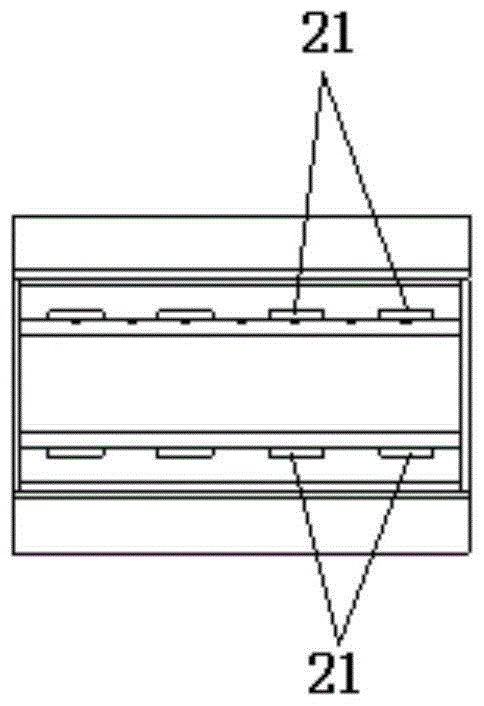

[0045] Figure 1 to Figure 7 The structure of the flared trailing edge concave cavity combustion chamber with rectangular cross-section is shown. Such as Figure 1 to Figure 7 As shown, the combustion chamber of the scramjet engine of this embodiment includes an injection section 1, a rear edge sudden expansion type concave cavity 2, and an expansion section 3, and a group of fuel injection holes 11 are horizontally arranged on the injection section 1, and also include The deflector 21 is arranged at the front edge of the rear edge of the suddenly expanding concave cavity 2 to control the development form of the shear layer.

[0046] By arranging a deflector 21 at the front edge of the trailing edge flared cavity 2, the lateral fuel injection on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com