Electric heating furnace

A technology for electric heaters and power supplies, applied in the field of electric heaters, can solve problems such as unfavorable environmental protection, polluted air, inconvenient movement, etc., and achieve the effects of efficient release of heat efficiency, convenient movement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

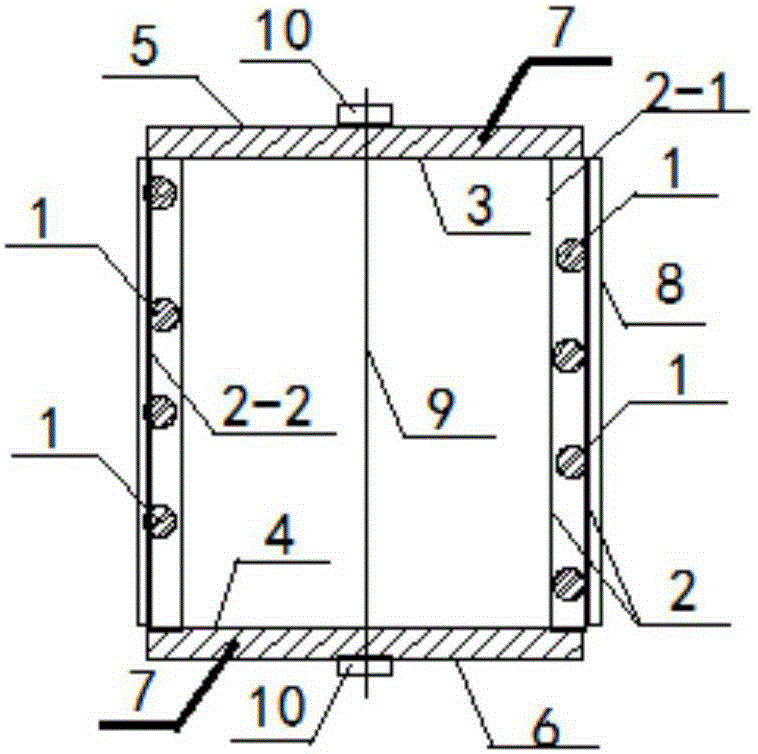

[0020] figure 1 A schematic structural view of the electric heater of the present invention is shown. Such as figure 1 As shown, the electric heater includes a heating element 1, a sealing body 2, a first sealing cover 3 and a second sealing cover 4, wherein the sealing body 2 includes an inner layer 2-1 and an outer layer 2-2, the The heating element 1 is spirally arranged between the inner layer 2-1 and the outer layer 2-2 and is in close contact with the outer layer 2-2. When the heating element 1 generates heat, it will transfer heat to the outer layer 2-2. The outer layer 2-2, the outer layer 2-2 can dissipate heat evenly, and because the heating element 1 is arranged in a spiral, the heating element 1 can generate heat evenly, instead of being limited to a certain place for heat dissipation , making heating efficient. The first sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com