A compressor exhaust temperature control method and system for a low-temperature enthalpy-injecting strong heat unit

A temperature control method and temperature control system technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve problems beyond safety, fluctuations, large fluctuations in compressor discharge temperature, etc., and achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

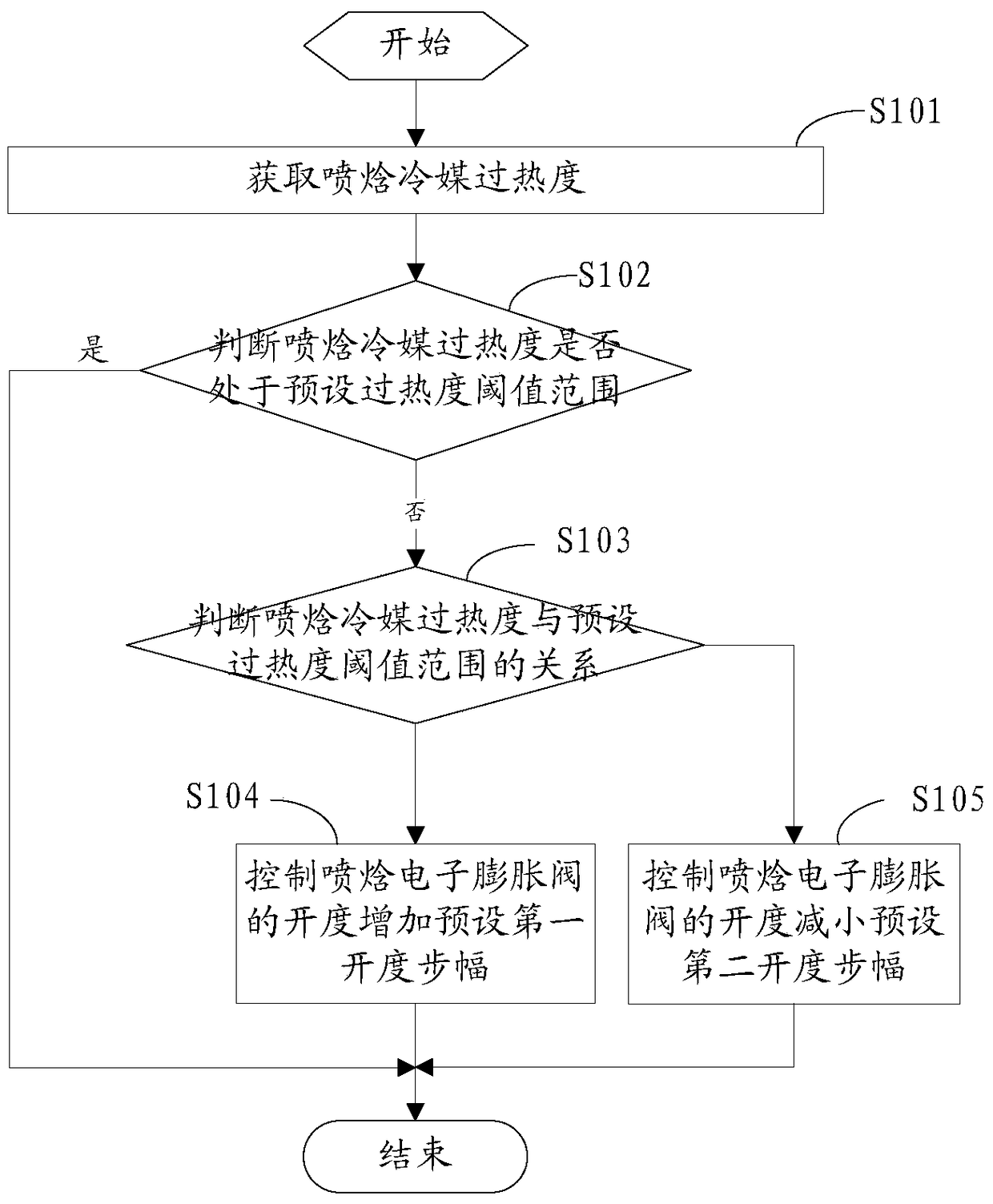

[0050] figure 1 This is a flowchart of a method for controlling the compressor discharge temperature of a low-temperature enthalpy-injection heat unit provided by an embodiment of this application.

[0051] Such as figure 1 As shown, the compressor exhaust temperature control method provided in this embodiment is applied to the controller of the low-temperature enthalpy injection heat unit, and includes the following steps:

[0052] S101: Obtain the superheat of the spray enthalpy refrigerant.

[0053] Firstly, the superheat of the spray enthalpy refrigerant is obtained through the spray pressure of the refrigerant spray port and the actual temperature.

[0054] S102: Determine whether the superheat of the injection enthalpy refrigerant is within a preset superheat threshold range.

[0055] The preset superheat threshold range is a preset superheat range, and the specific value range is selected according to actual measurement and empirical formulas. Judging whether it is within the pr...

Embodiment 2

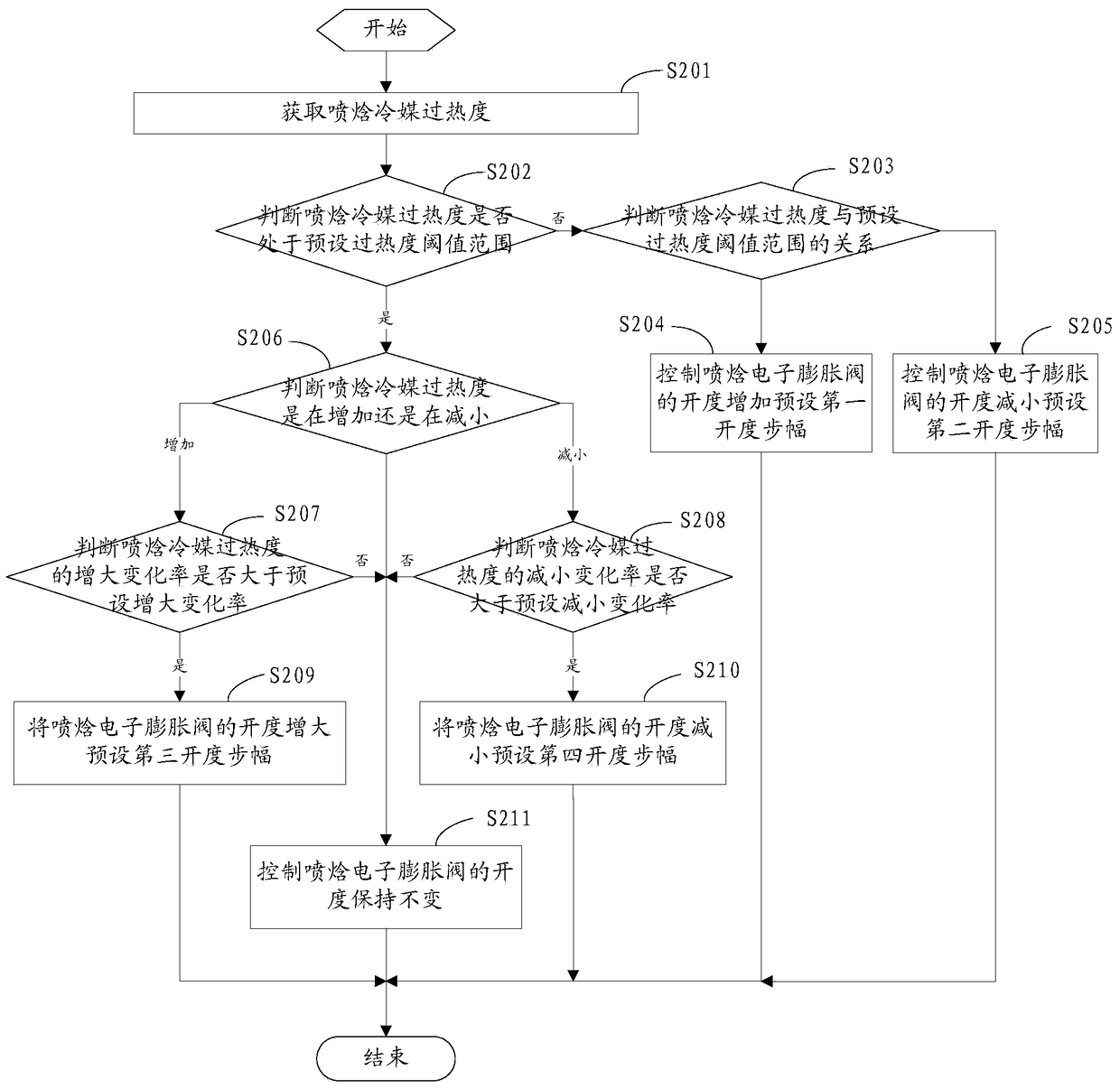

[0072] figure 2 It is a flow chart of another method for controlling the compressor discharge temperature of a low-temperature enthalpy-injected heat unit provided by an embodiment of this application.

[0073] As shown in the figure, the compressor discharge temperature control method provided in this embodiment is applied to the controller of the low-temperature enthalpy injection heat unit, and includes the following steps:

[0074] S201: Obtain the superheat of the spray enthalpy refrigerant.

[0075] Firstly, the superheat of the spray enthalpy refrigerant is obtained through the spray pressure of the refrigerant spray port and the actual temperature.

[0076] S202: Determine whether the superheat of the injection enthalpy refrigerant is within a preset superheat threshold range.

[0077] The preset superheat threshold range is a preset superheat range, and the specific value range is selected according to actual measurement and empirical formulas. Judging whether it is within th...

Embodiment 3

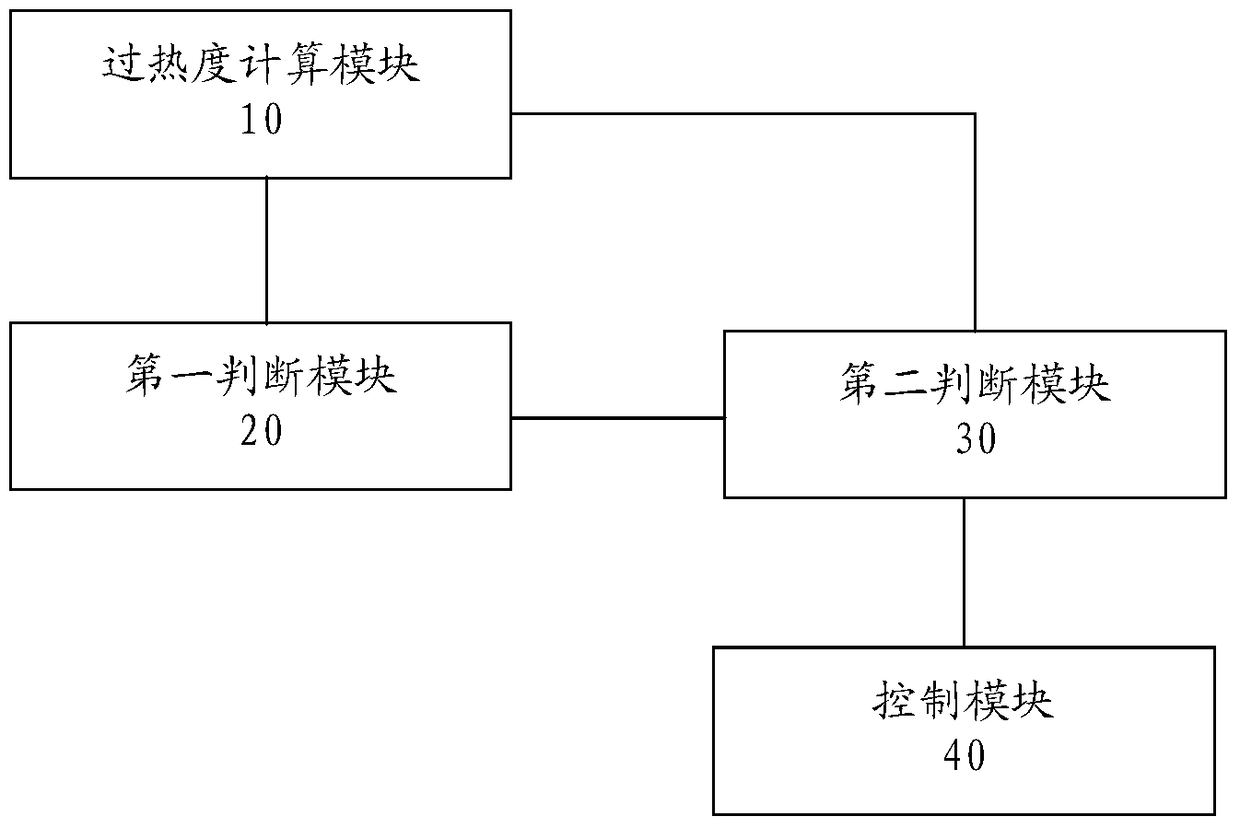

[0098] image 3 This is a schematic diagram of a compressor exhaust temperature control system of a low-temperature enthalpy-intensified heat unit provided by another embodiment of this application.

[0099] Such as image 3 As shown, the compressor discharge temperature control system provided in this embodiment includes a superheat calculation module 10, a first judgment module 20, a second judgment module 30, and a control module 40.

[0100] The superheat degree calculation module 10 is used to calculate the spray pressure and actual temperature of the refrigerant spray port to obtain the spray enthalpy refrigerant superheat degree.

[0101] The first judging module 20 is used to judge whether the superheat of the injection enthalpy refrigerant is within a preset superheat threshold range.

[0102] The preset superheat threshold range is a preset superheat range, and the specific value range is selected according to actual measurement and empirical formulas. Judging whether it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com