Vapor Compression Refrigeration Cycle Expansion Work Recovery System

A compression refrigeration and recovery system technology, applied in the direction of refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems of rising exhaust temperature, limitation of temperature difference between cold and heat sources, and increase of compressor pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

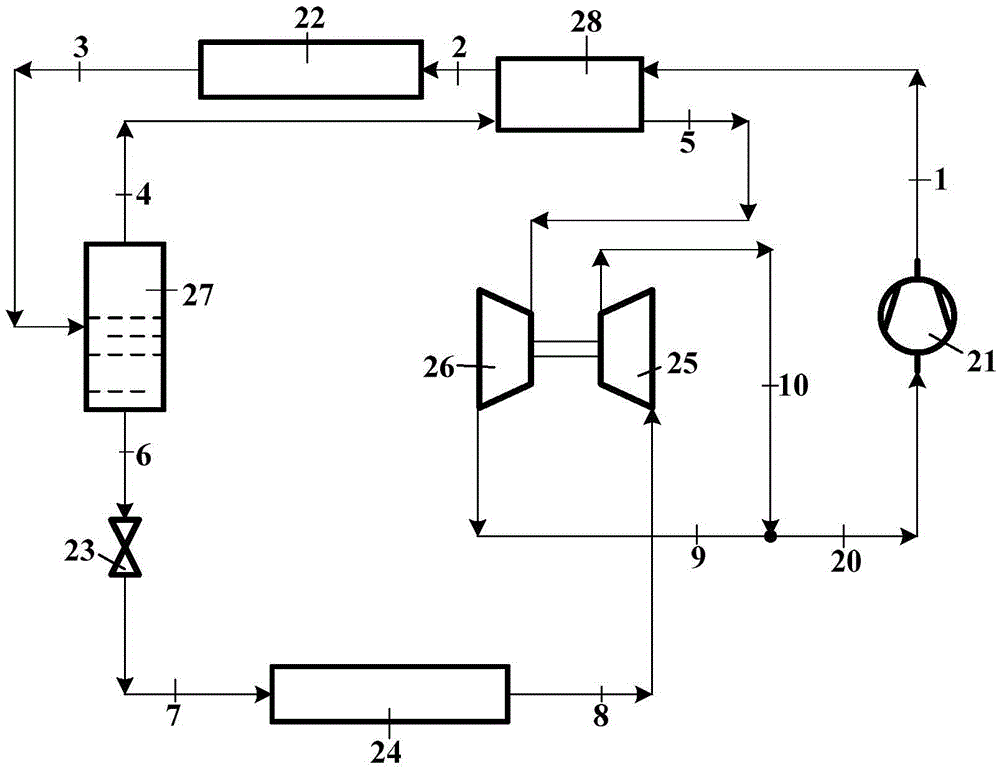

[0058] Figure 5 It is the temperature-entropy diagram of the vapor compression refrigeration cycle using R134a as the working medium, the state points 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 1 in the figure ', 2', 9', 10' and 20' (1', 2', 9', 10' and 20' are the import and export states of the isentropic compression or expansion process) and image 3 Consistent with that shown. Taking the heat pump system as an example, the parameters of each state point including temperature, pressure and enthalpy are listed in Table 2. In the temperature-entropy diagram, the dotted line represents the isentropic expansion and compression process.

[0059] Table 2

[0060]

[0061]

[0062] According to the literature, the isentropic efficiency of the scroll expander using 134a as the working fluid is set at 0.7. Considering that the isentropic efficiency of the compressor is significantly affected by the compression ratio, for this compressor, its isentropic efficiency is calculated as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com