No-blind zone double-color water gauge

A water level gauge, no blind spot technology, applied in liquid/fluid solid measurement, engine lubrication, instruments, etc., to avoid water level blind spots, easy to operate, and solve the effects of water level blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

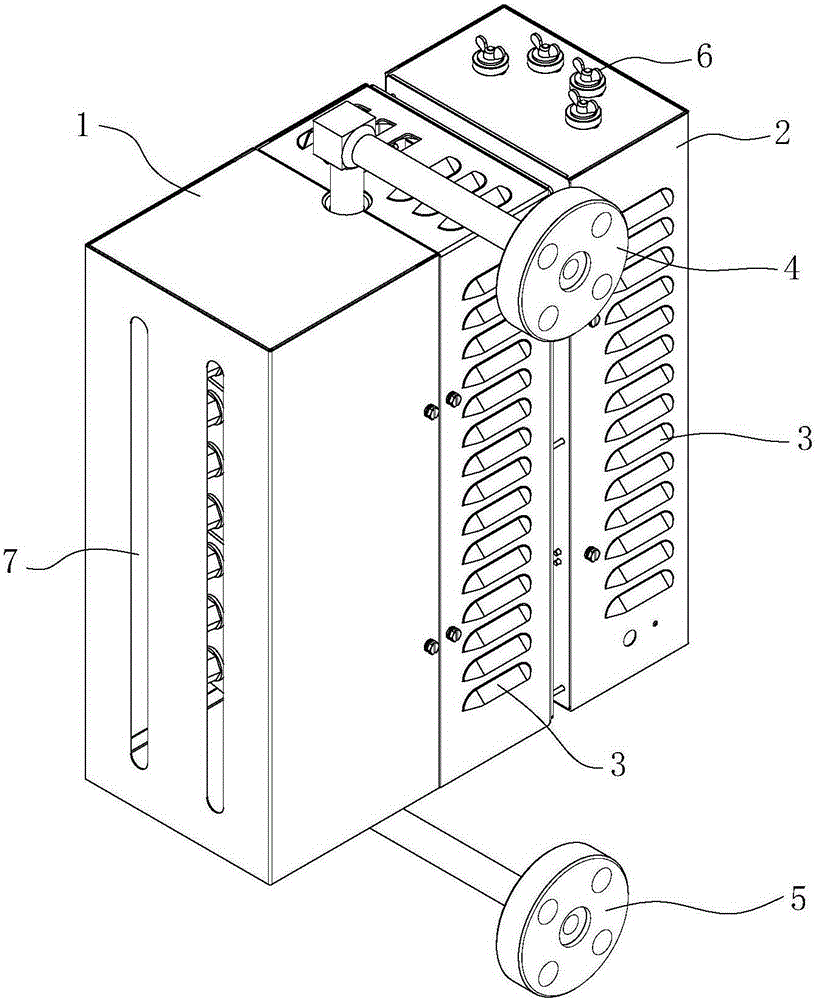

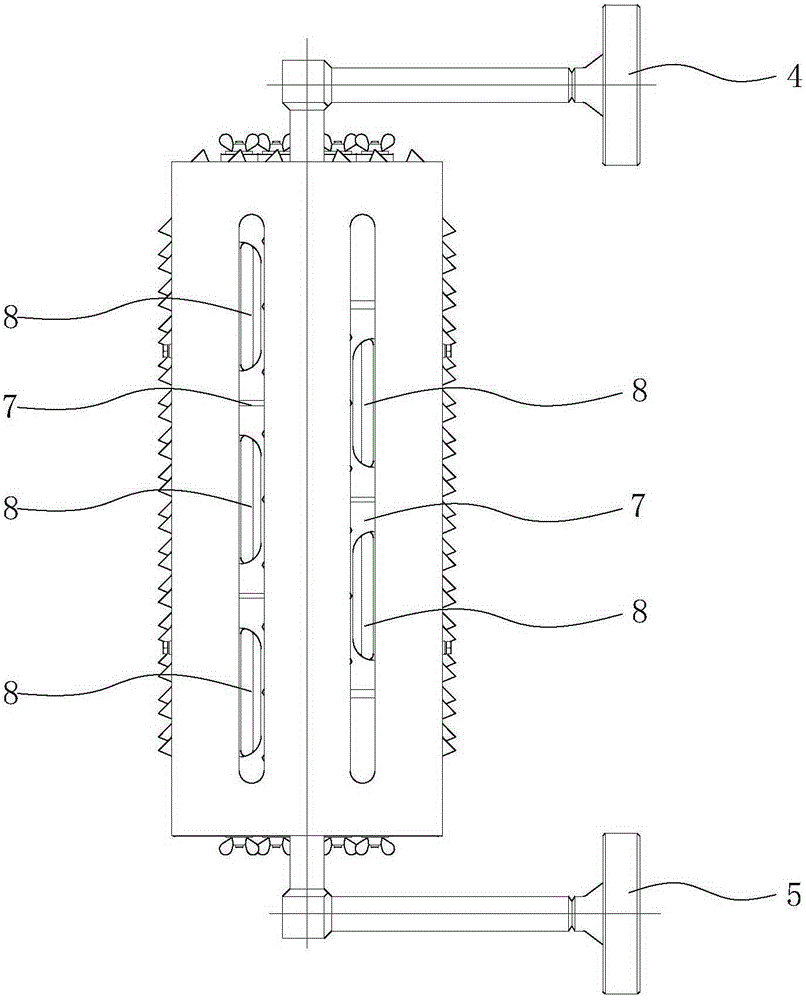

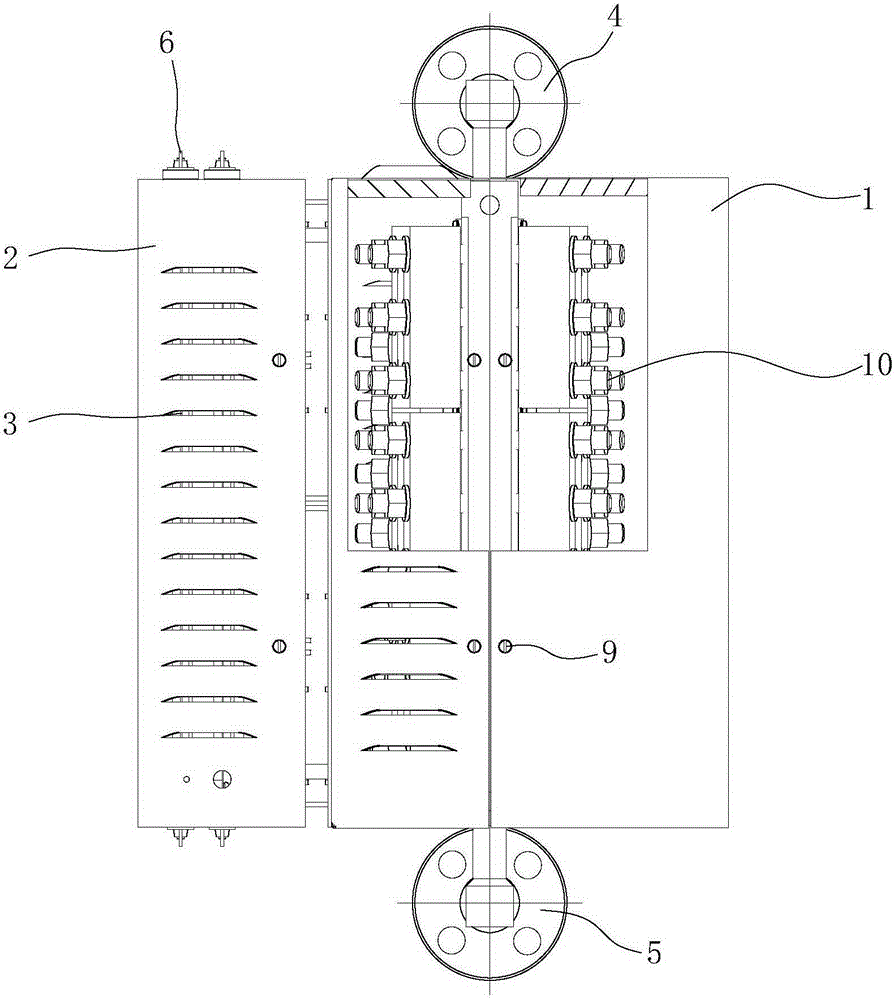

[0021] Such as Figure 1 to 3 As shown, a two-color water level gauge without blind spots includes a light source front cover 1 and a light source rear cover 2 made of stainless steel. A heat shield is arranged between the light source front cover 1 and the light source rear cover 2, and the light source front cover 1 Two see-through holes 7 spaced apart are vertically opened on one side of the rear cover 2 away from the light source. The front cover 1 of the light source is provided with a transparent surface body 10 composed of mica and glass, and the upper part of the surface body 10 passes through an upper connecting tube After passing through the light source front cover 1, connect the steam side flange 4, and the steam side flange 4 connects to the air space of the steam drum. The lower part of the meter body 10 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com