Pressure measurement system with photo-elasticity pressure sensor

A pressure sensor and measurement system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring the change of optical properties of materials when they are stressed, etc., can solve sensor damage, affect long-term monitoring of structures, etc. problem, to achieve the effect that the range can be changed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] A pressure measuring system adopting a photoelastic pressure sensor comprises a photoelastic pressure sensor 4 and a data acquisition operation platform 18, the positions of the photoelastic pressure sensor 4 and the data acquisition operation platform 18 are relative, and the photoelastic pressure The distance between the sensor 4 and the data acquisition operation platform 18 is adjustable;

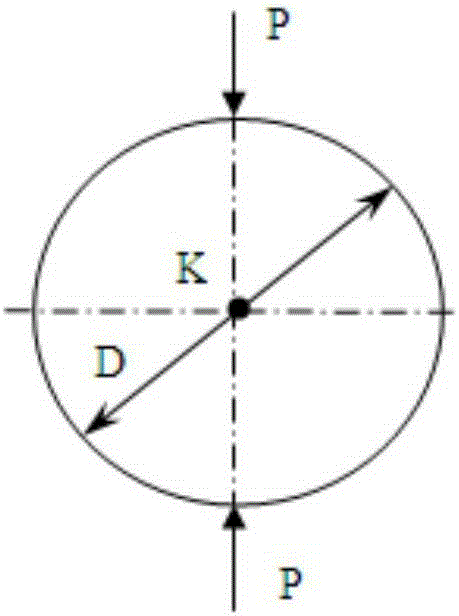

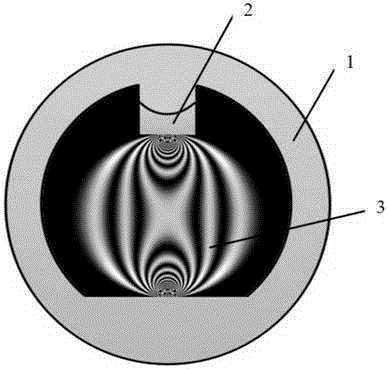

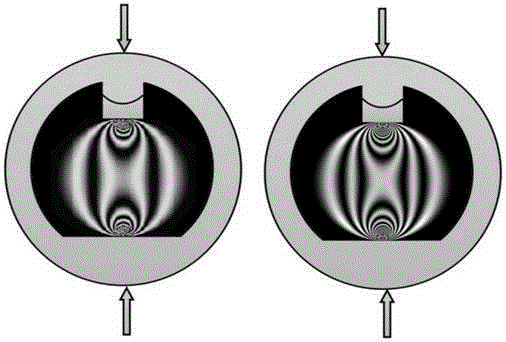

[0030] The photoelastic pressure sensor 4 includes an outer ring 1 and a curved spacer 2 and a test piece 3 inside the ring 1. The upper part of the inner side of the ring 1 is provided with a downwardly curved arcuate bump, The lower part of the inside of the ring 1 is a platform, the curved pad 2 is located above the inside of the ring 1, the test piece 3 is located below the inside of the ring 1, the curved pad 2 and the test piece P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com