A test bench for testing the circulating pressurization function of a gas water heater

A gas water heater and cycle pressurization technology, which is applied in the field of testing test benches, can solve the problems that the test benches do not keep up with each other, the reliability of test data is not high, and the structure of the test benches is complex, etc. Simple, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

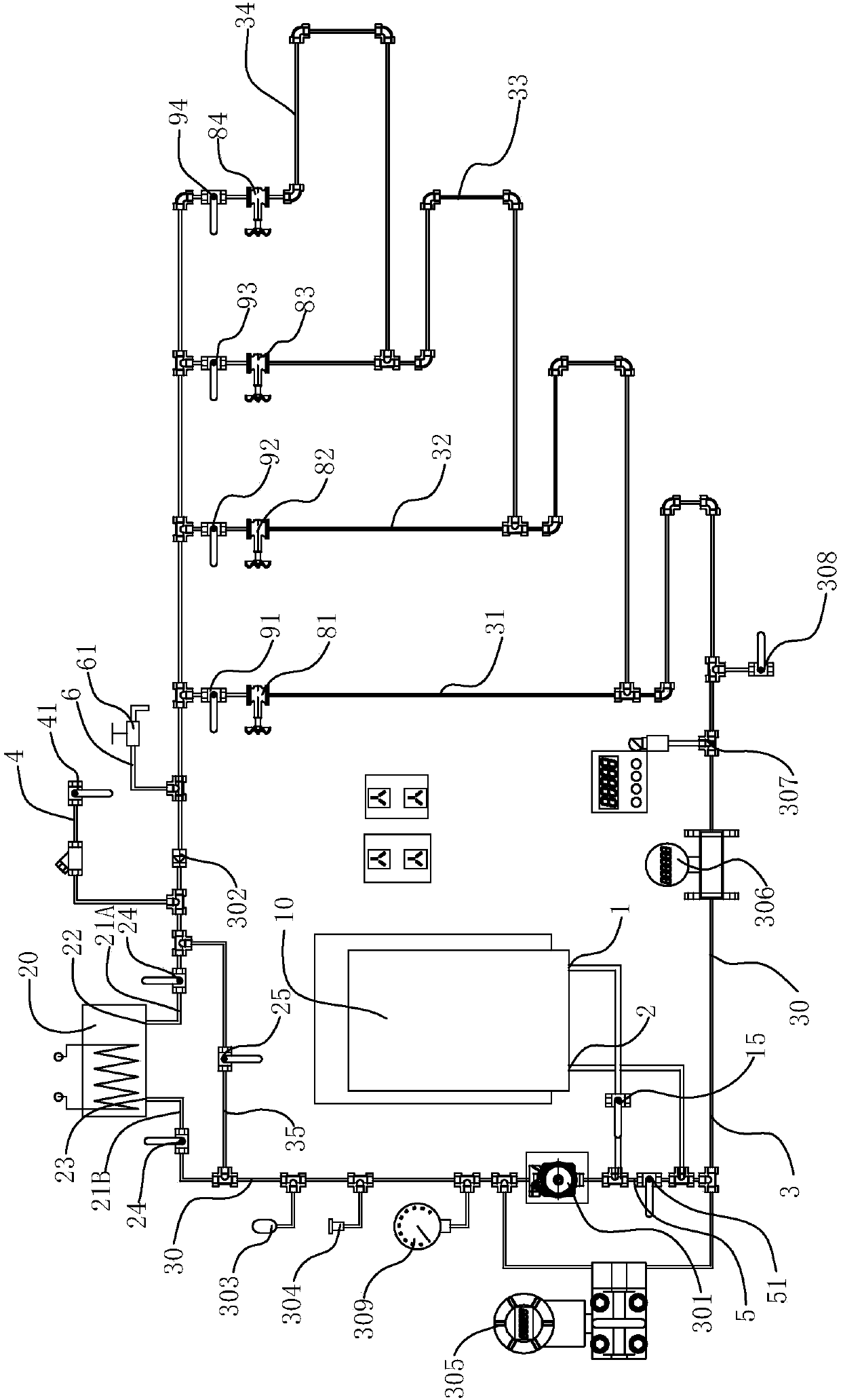

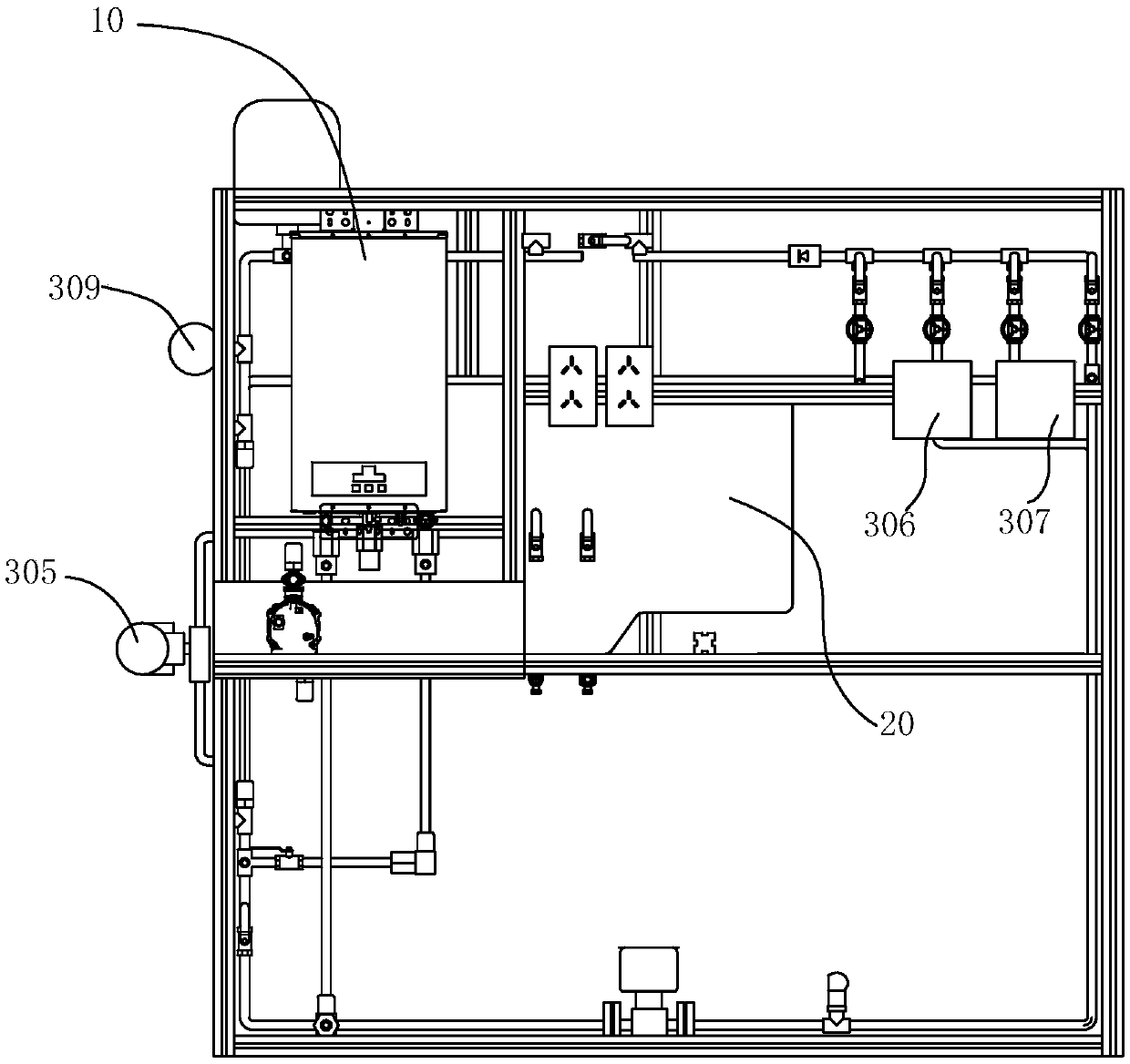

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] Such as Figure 1-2 As shown, the detection test bench for the circulating pressurization function of the gas water heater of the present invention includes an electric water heater 20 located in the middle of the test bench. There is a pipeline for connecting the gas water heater on the test bench, and the pipeline has two ports connected to the gas water heater 10 to be tested, and the two ports are the water inlet port 1 and the water outlet port 2 respectively. A circulating water pipe 3 is connected between the two ports, and the circulating water pipe is provided with a water pump 301 so that the water in the circulating water pipe 3 can circulate. 4 is provided with a replenishment gate valve 41, so that the circulating water pipe 3 can replenish cold water through the cold water replenishment pipe 4. The circulating water pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap