Device for reading medical film

A technology for medical imaging and film reading, applied in optics, optical components, instruments, etc., can solve problems such as reducing the use experience, difficult to ensure the smooth fit between the light film and the backplane, and wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

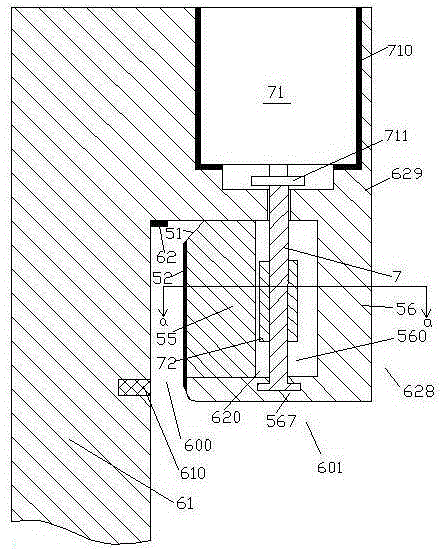

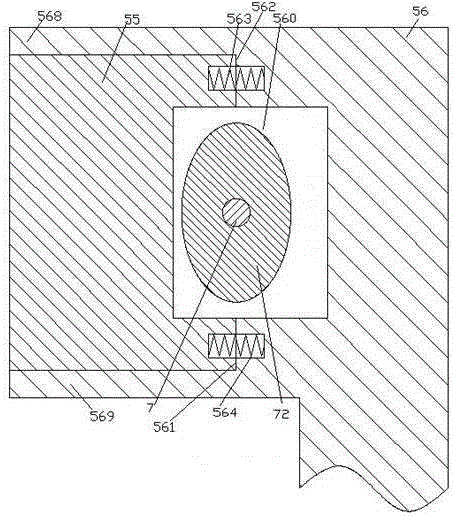

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] A film reading device for medical images according to an embodiment includes a backlight frame body 61 with a backlight source, the backlight source is used to illuminate medical image light films for reading, and the backlight frame body 61 A horizontally extending clamping protruding part 601 is provided at the upper edge of the backlight panel. The clamping protruding part 601 includes an upper supporting frame body 629 integrally formed with the backlight frame body 61 and used to carry the driving motor 71 and At least one lower bearing frame chamber 628 integrally connected with the upper bearing frame body 629, the lower bearing frame chamber 628 includes a front wall portion 569, a rear wall portion 568, a bottom wall 567, the upper bearing frame body 629 and the cavity 620 surrounded by the right side part 56 of the bearing frame chamber, the clamping slider 55 can be slid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com