Optimal Control System Method Based on Exemplary System

An optimization control and control system technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as inability to ensure optimization results, complex identification algorithms, and difficulty in popularization, etc., to achieve easy mastery and popularization, The steps and algorithms are intuitive and simple, and the implementation conditions are easy to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

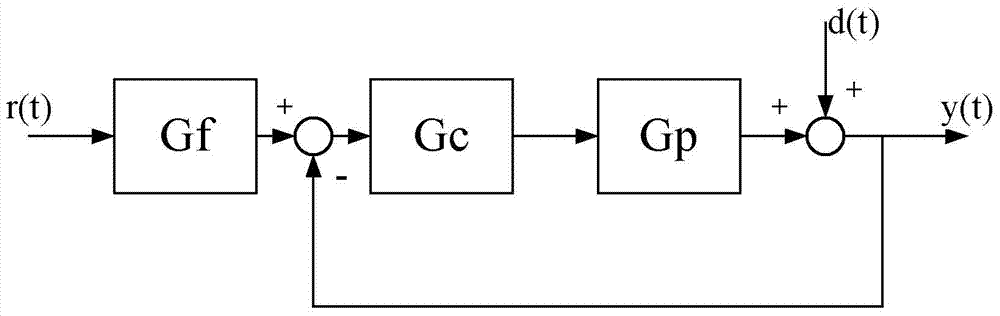

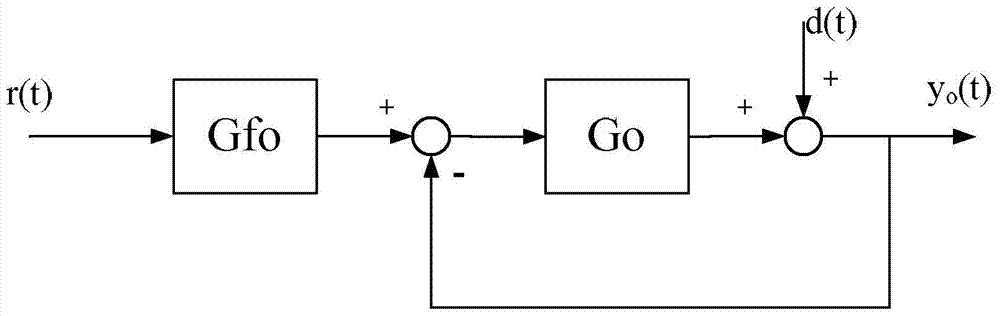

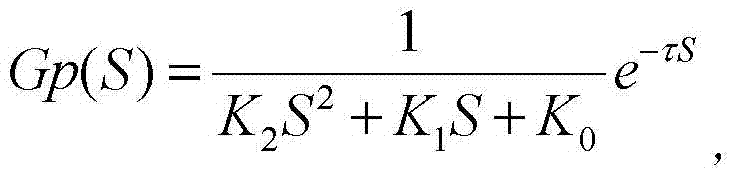

[0035] According to an embodiment of the present invention, the control system includes a filter Gf, a controller Gc, and a controlled object Gp, wherein the mathematical model specifying the controlled object Gp is:

[0036]

[0037] (K 2 ≥0;K 1 >0;K 0 ≥0;τ>0)

[0038] This model basically covers the common first-order (K2=0), second-order, integral (K0=0), non-integral and time-delay (τ>0) objects that account for the majority of industrial processes, where , S is the Laplace operator, K 0 is the integral factor, K 1 is the scaling factor, K 2 Be differential factor, τ represents time lag value; The mathematical model of specifying described controller Gc is:

[0039]

[0040]

[0041] Ti=K 1 / K 0

[0042] Td=K 2 / K 1

[0043]

[0044] In the formula, Kp, Ti, Td and Tf are controller parameters, Kp is proportional coefficient, Ti is integral coefficient, Td is differential coefficient, Tf is filter coefficient;

[0045] Specify the mathematical model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com