A kind of composite titanate negative electrode material of lithium ion secondary battery and its synthesis method

A composite titanate and secondary battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of safety and long life hindering the wide application of lithium-ion batteries, rapid decay of battery cycle performance, and loss of reversible capacity , to achieve good processing performance, cheap raw materials, and good power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

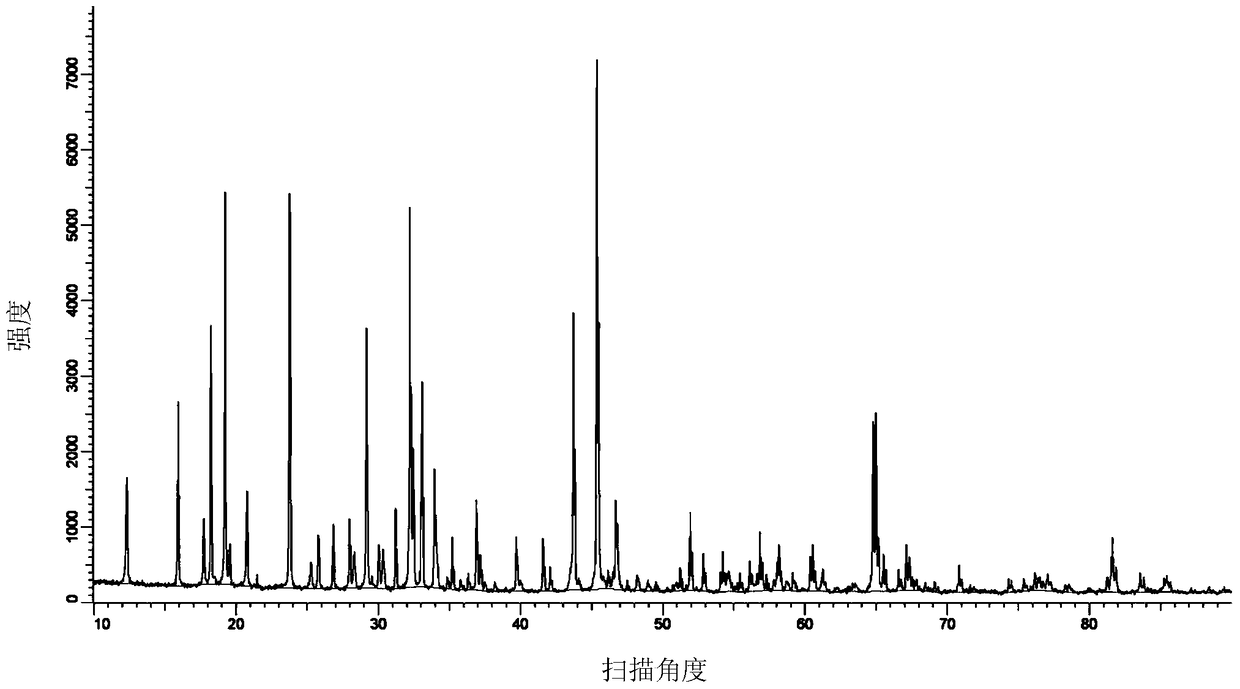

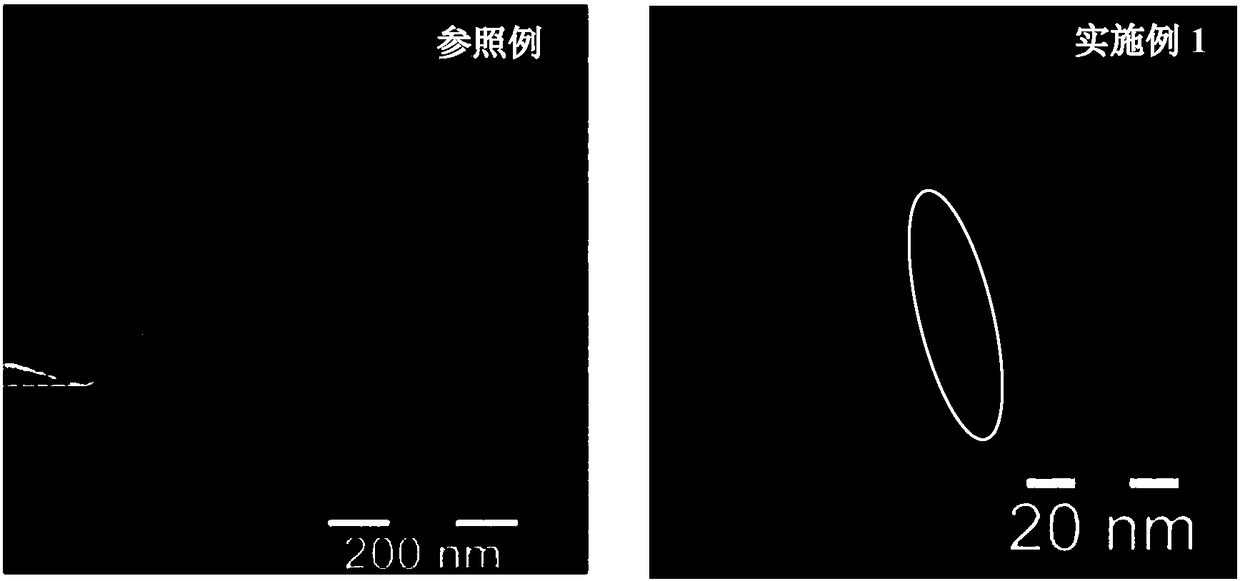

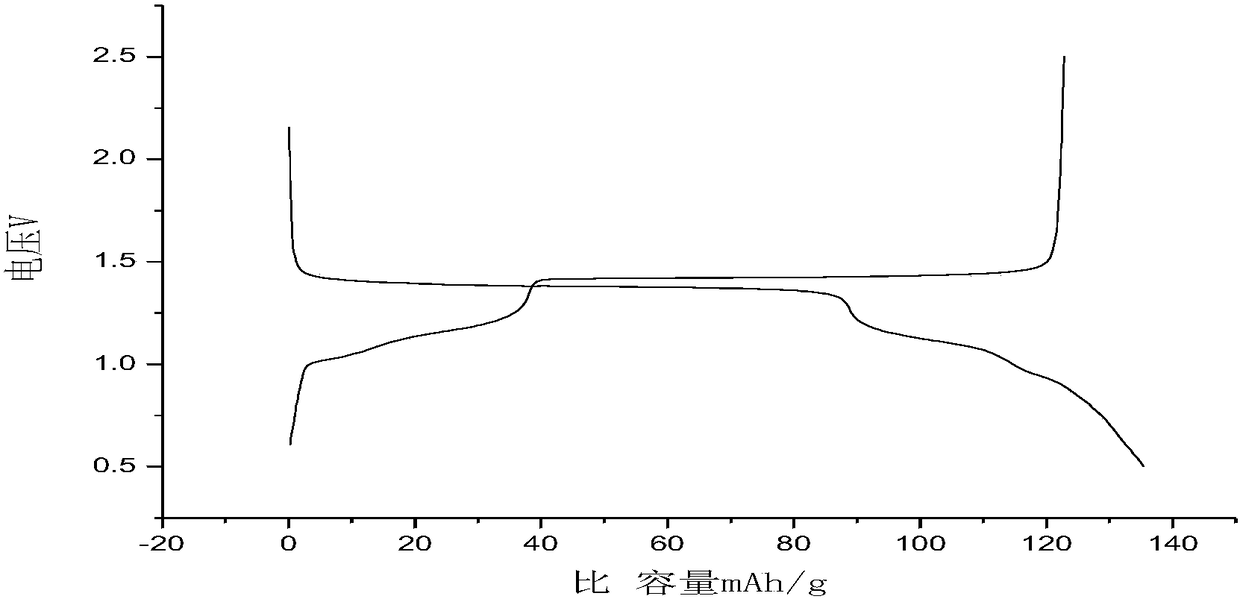

[0037] Li 2 SrTi 5.98 al 0.02 o 13.99 Preparation of -0.2C

[0038] Lithium carbonate, anatase titanium dioxide, aluminum hydroxide, strontium carbonate and glucose are selected as raw materials, and the molar ratio of the synthesized product is Li:Sr:Ti:Al:C=2:1:5.98:0.02:0.2. In the atmosphere furnace, flush the furnace with nitrogen until the oxygen content in the furnace is less than 100ppm, adjust the gas flow to 1.5L / min, raise the temperature to 500°C at a rate of 5°C / min, keep it for 8 hours, cool naturally to room temperature, and grind After pulverization, the temperature was raised to 1100°C at 5°C / min for 24 hours, and then naturally cooled to room temperature to obtain a gray-black product.

Embodiment 2

[0040] Li 2.01 Sr 0.8 Ba 0.2 Ti 5.95 Zr 0.05 o 13.98 Preparation of -0.01TiN

[0041] Lithium carbonate, metatitanic acid, zirconium dioxide, strontium hydroxide, barium hydroxide and urea were selected as raw materials, and the ingredients were prepared according to the molecular formula of the above synthetic products. After mixing, they were placed in an atmosphere furnace and passed through N 2 Wash the furnace until the oxygen content in the furnace is less than 100ppm, then introduce reducing gas (N 2 with H 2 The mixture gas, volume ratio N 2 :H 2 =95:5), raised to 600°C at a heating rate of 5°C / min, kept for 4 hours, cooled naturally to room temperature, ground and pulverized, raised to 1000°C and kept for 24 hours, and naturally cooled to room temperature to obtain a light blue product.

Embodiment 3

[0043] Li 2.05 SrTi 5.9 Y 0.1 o 14 -0.03Al 2 o 3 preparation of

[0044] Lithium carbonate, anatase titanium dioxide, strontium carbonate and yttrium oxide are first selected as raw materials, and the ingredients are mixed according to the molar ratio Li:Sr:Ti:Y=2.05:1:5.9:0.1. After mixing, they are placed in a muffle furnace and blown into air. , first raise the temperature to 600°C at a rate of 5°C / min, keep it warm for 4 hours, and then cool it down to room temperature naturally, then raise the temperature to 1100°C and keep it for 12 hours, and then cool it down to room temperature naturally to get Li 2.05 SrTi 5.9 Y 0.1 o 14 matrix. Then according to the synthesis target product Li 2.05 SrTi 5.9 Y 0.1 o 14 :Al 2 o 3 (Molar ratio)=1:0.03, in Li 2.05 SrTi 5.9 Y 0.1 o 14 Aluminum hydroxide was added to the mixture, and after grinding and mixing, the powder was placed in an atmosphere furnace, and kept at 600°C for 8 hours in an air atmosphere, and natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com