Equipment for pressing rotor shaft in rotor ring of motor

A rotor shaft and equipment technology, which is applied to welding equipment, metal processing equipment, manufacturing stator/rotor body, etc., can solve the problems of less functions and waste of manpower, and achieve the effect of high automation and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

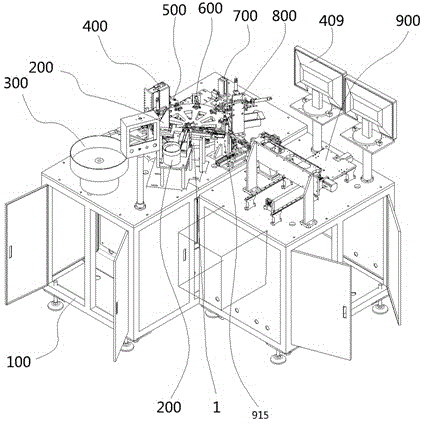

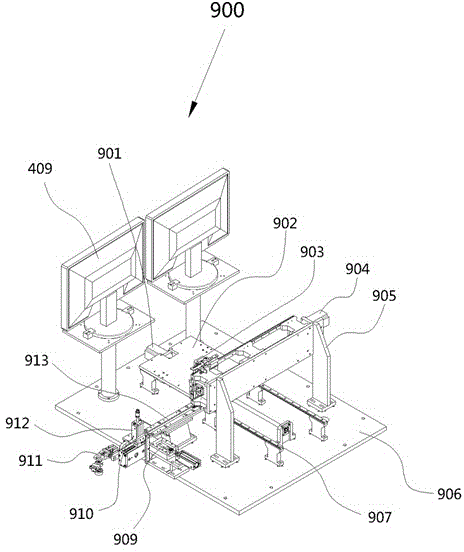

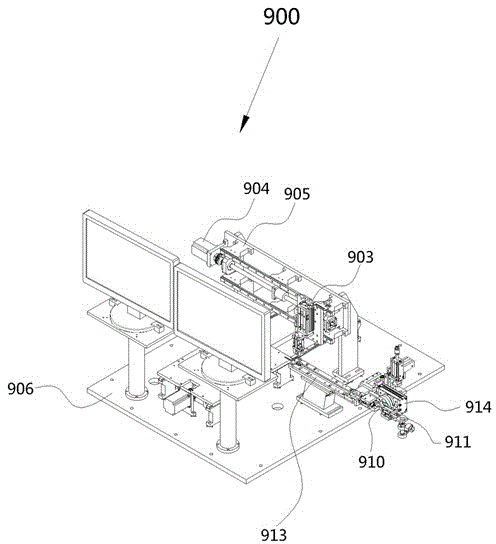

[0034]The equipment for rotating the motor to press the rotor shaft includes a workbench 100 on which the turntable device 1 is installed. The workbench 100 is sequentially installed with a rotor shaft supply device 200 along the side, a circle supply mechanism 300, a CCD camera mechanism 400, a pressure welding Mechanism 500, slag removal mechanism 600, defective product removal mechanism 800 and unloading mechanism 900. Described turntable device 1 comprises disc 15, and support 14 is installed below disc 15, and the motor one 13 that drives disc 15 rotation is installed on described support 14 side; Motor one 13 drives disc 15 to rotate through belt 12 transmission, Motor one 13 is a PLC controlled motor, and a workpiece placement groove 16 is installed on the disc 15 . The workpiece puts groove 16 side also to be equipped with stopper 11, and the main function of stopper 11 is to be used for blocking workpiece.

[0035] The rotor shaft supply device 200 includes a base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com