Device and method for laterally guiding a rolled or cast product on a transport track

A technology for guiding devices and transport lines, which is applied in the field of devices for rolling or casting products, and can solve the problems of loss of guiding length, affecting the length of abutment, and the length of guiding guide plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

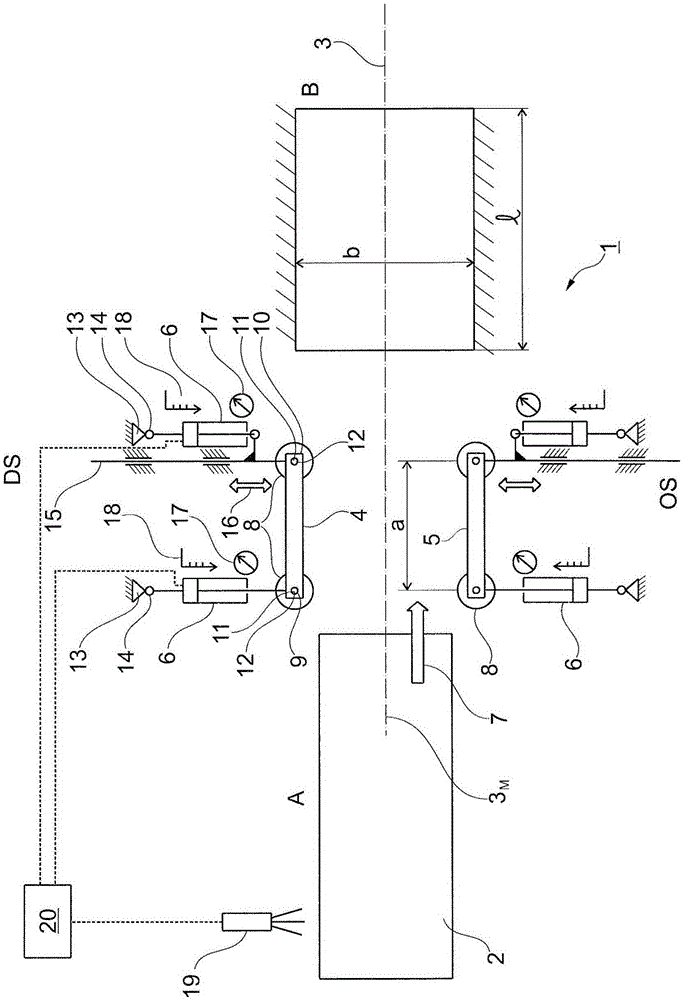

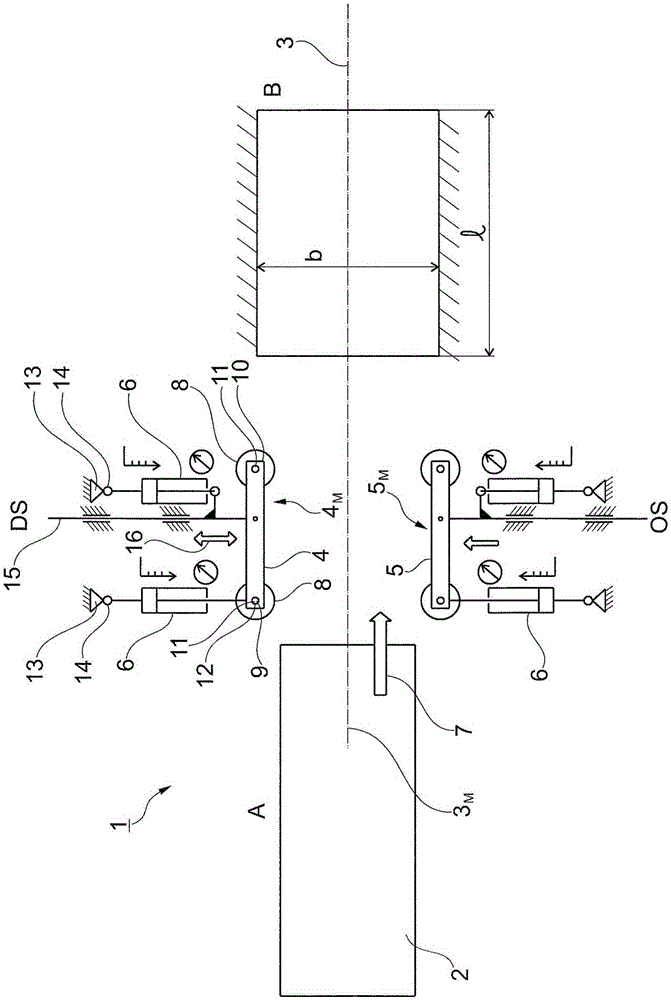

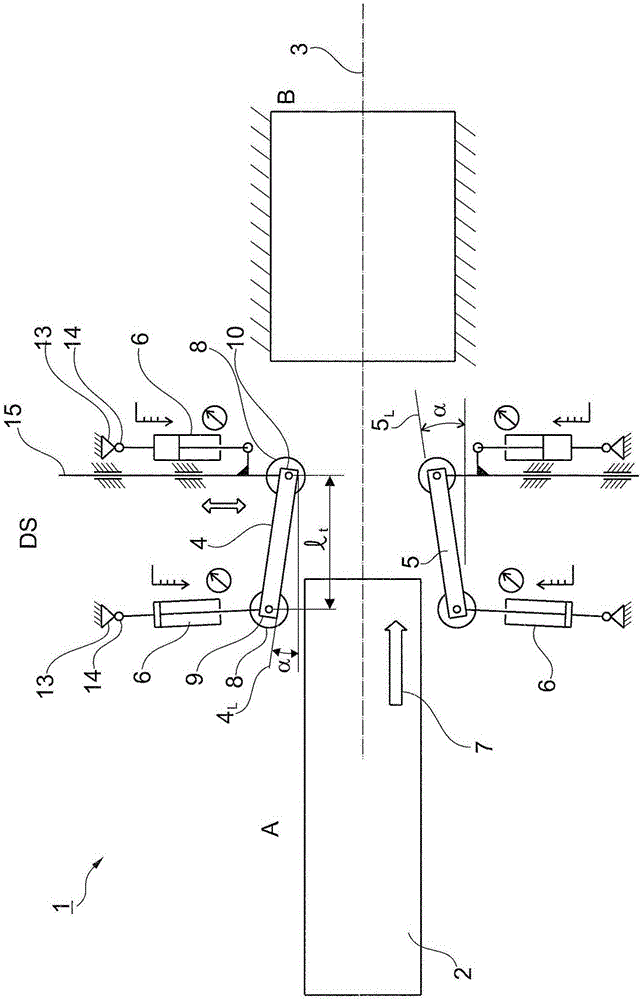

[0028] exist figure 1A schematically simplified top view of the device according to the invention is shown in FIG. 2 , with which a cast product 2 can be guided laterally on or along a transport line 3 . Transport line 3 in figure 1 In simplified form, it is indicated by a dotted line, wherein the conveying line 3 can be a component (roller table) of a rolling line. Hereinafter, the symmetrical middle part of the transportation line 3 is referred to as the middle part of the transportation line and in figure 1 Using "3 M " to indicate. The cast product 2 can be a metal strip, a slab or other rolled parts. This should not be considered restrictive, and the cast product 2 will always be referred to as a slab hereinafter.

[0029] The device 1 comprises a first guiding fence 4 and a second guiding fence 5 . The guide rails 4 , 5 are arranged on both sides of the transport line 3 and opposite each other. exist figure 1 "DS" or "OS" is used in , to designate the drive side or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com