Aluminum alloy extrusion die waste aluminum automatic removal device

An extrusion die and automatic removal technology, applied in the field of automatic removal devices, can solve the problems of inability to recycle aluminum alloys, low work efficiency, high labor intensity, etc., and achieve the effects of high work efficiency, reduced labor intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

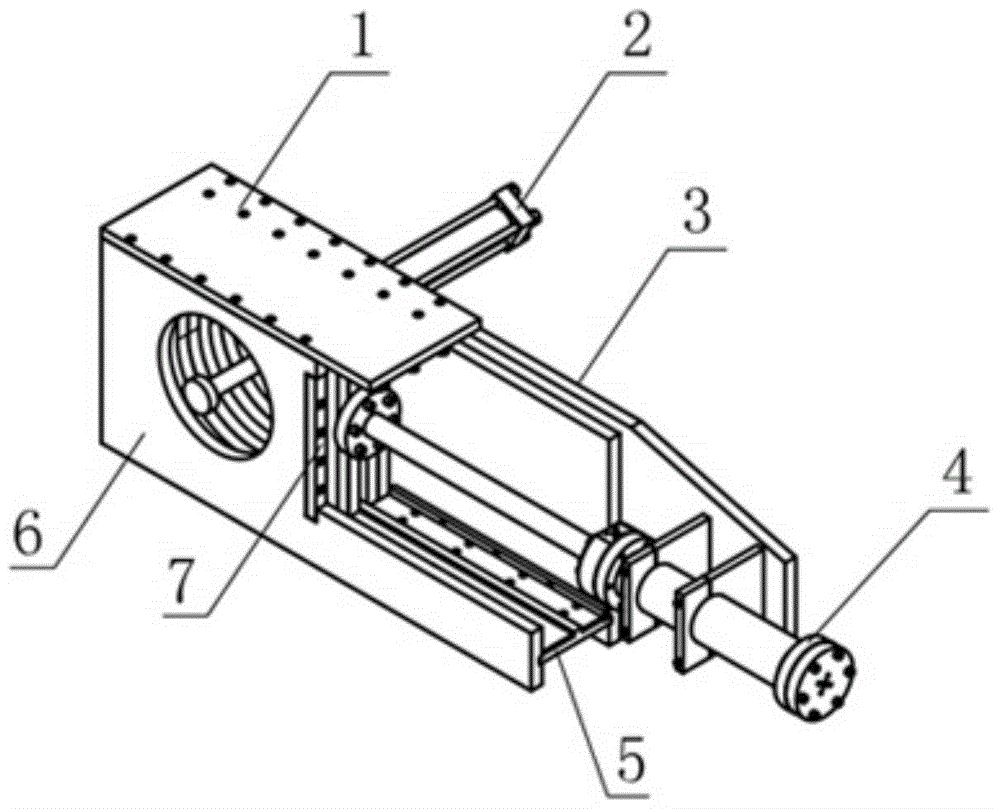

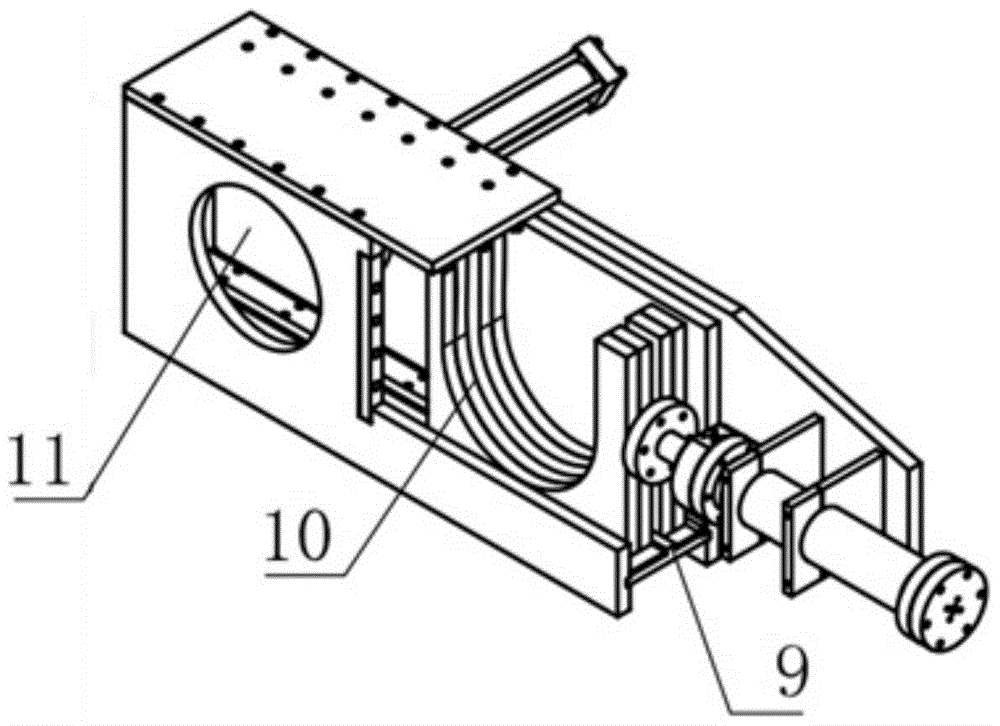

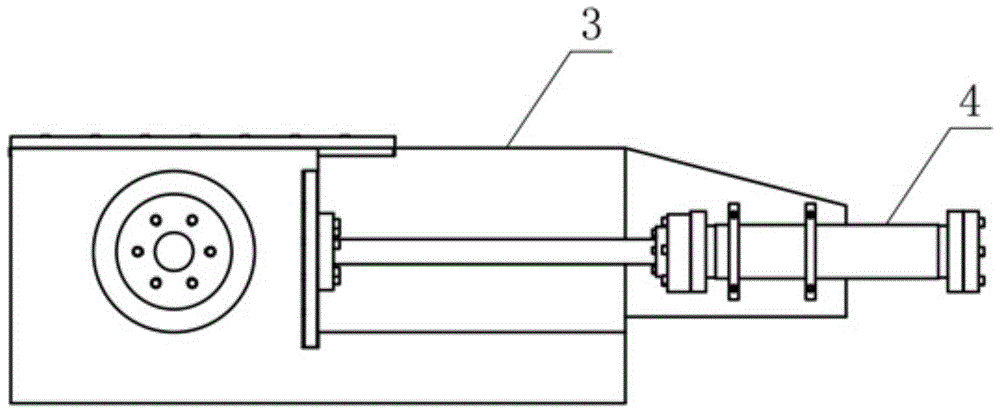

Embodiment 1

[0026] see as Figure 1-5 As shown, the aluminum alloy extrusion die automatic removal device for scrap aluminum of the present invention includes an upper platen 1, a demoulding hydraulic cylinder 2, a rear clamping plate 3, a shearing hydraulic cylinder 4, a base 5, a front clamping plate 6, a scissors blade 7, a left Splint 8, guide block 9, mold base 10 and die outlet 11; described splint includes front splint 6, rear splint 3 and left splint 8, front splint 6 is located at the front end of base 5, rear splint 3 is located at base 5 The rear end of the left clamping plate 8 is located at the left end of the base 5; the upper clamping plate 1 is installed on the top of the rear clamping plate 3, the front clamping plate 6 and the left clamping plate 8, and the upper clamping plate 1 and the base 5 are provided with guides. Block 9, the mold base 10 is installed on the upper platen 1 and the guide block 9 of the base 5; the hydraulic cylinder includes a demoulding hydraulic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap