Thermoforming mold for segmented reinforcing of boron steel material

A segmented strengthening and thermoforming technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effects of high product quality and stability, convenient mold maintenance, and convenient product changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

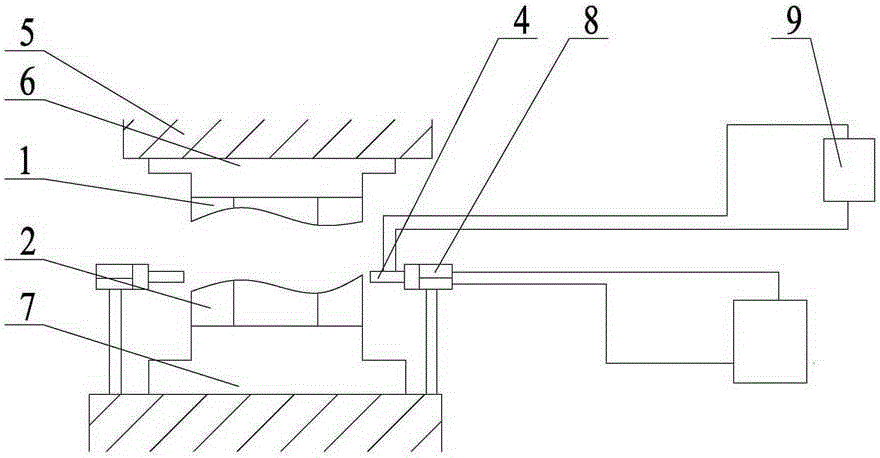

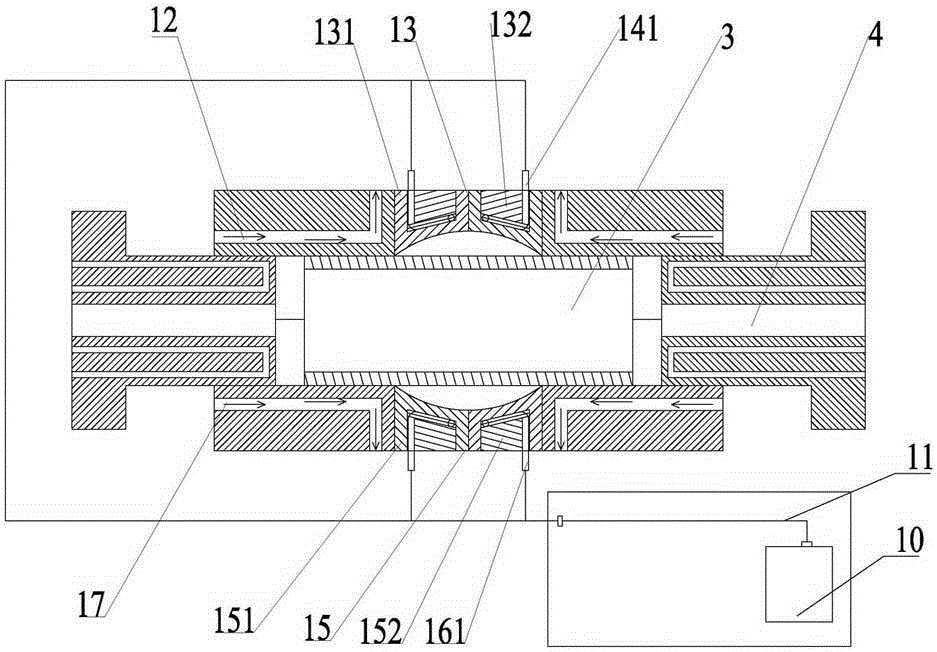

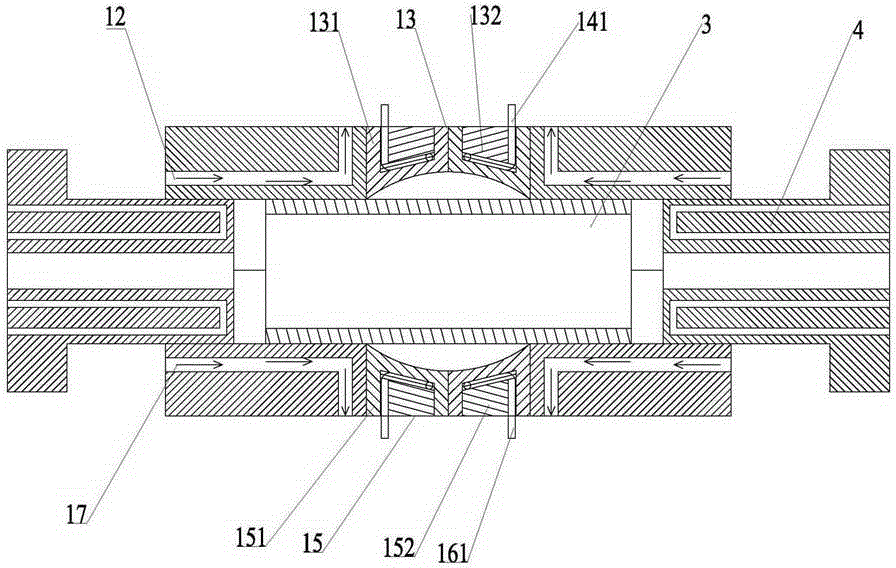

[0043] Embodiment one proposes the thermal forming die of boron steel plate: by Figure 1 to Figure 5 It can be seen that the present invention includes: upper mold base, upper mold hard zone forming insert, upper mold hard zone cooling water channel, upper mold soft zone forming insert, upper mold soft zone temperature control device, the temperature of the upper mold soft zone The control device includes a cooling water circuit in the soft zone of the upper mold and a heating device in the soft zone of the upper mold. The zone forming insert core is installed in the soft zone forming insert shell of the upper mold;

[0044] Lower mold base, lower mold hard zone forming insert, lower mold hard zone cooling waterway, lower mold soft zone forming insert, lower mold soft zone temperature control device, the lower mold soft zone temperature control device includes lower mold soft zone Cooling water circuit and lower mold soft area heating device; the lower mold soft area forming...

Embodiment 2

[0066] Embodiment two proposes the thermoforming die of boron steel pipe: by Figure 1 to Figure 5 It can be seen that the present invention includes an upper mold base, an upper mold hard zone forming insert, an upper mold hard zone cooling waterway, an upper mold soft zone forming insert, and an upper mold soft zone temperature control device. The device includes a cooling water circuit for the soft zone of the upper mold and a heating device for the soft zone of the upper mold. The forming insert core is installed in the forming insert shell in the soft area of the upper mold;

[0067] The present invention also includes the lower die base, the forming insert in the hard area of the lower die, the cooling water channel in the hard area of the lower die, the forming insert in the soft area of the lower die, the temperature control device in the soft area of the lower die, and the sealing head, the temperature control in the soft area of the lower die The device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com