Method and device for engraving three-dimensional image on glass with regular cambered surface

A three-dimensional image and glass technology, used in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problem of inability to achieve 360-degree one-week engraving, etc., to meet processing needs, meet diverse needs, and facilitate adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

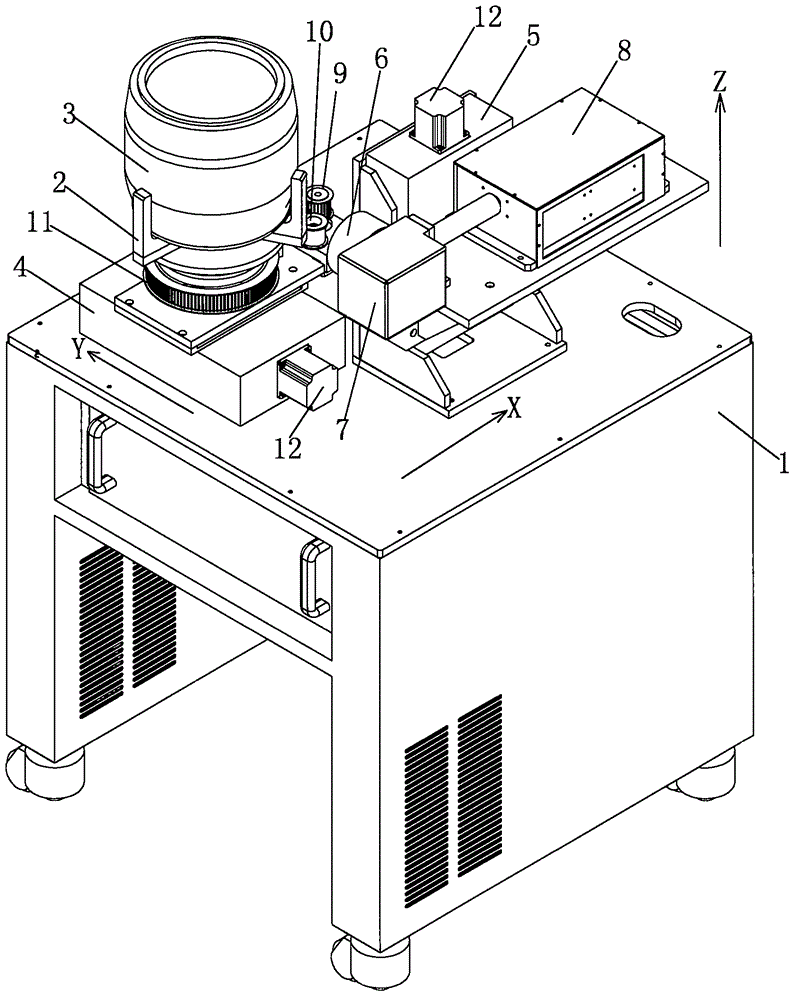

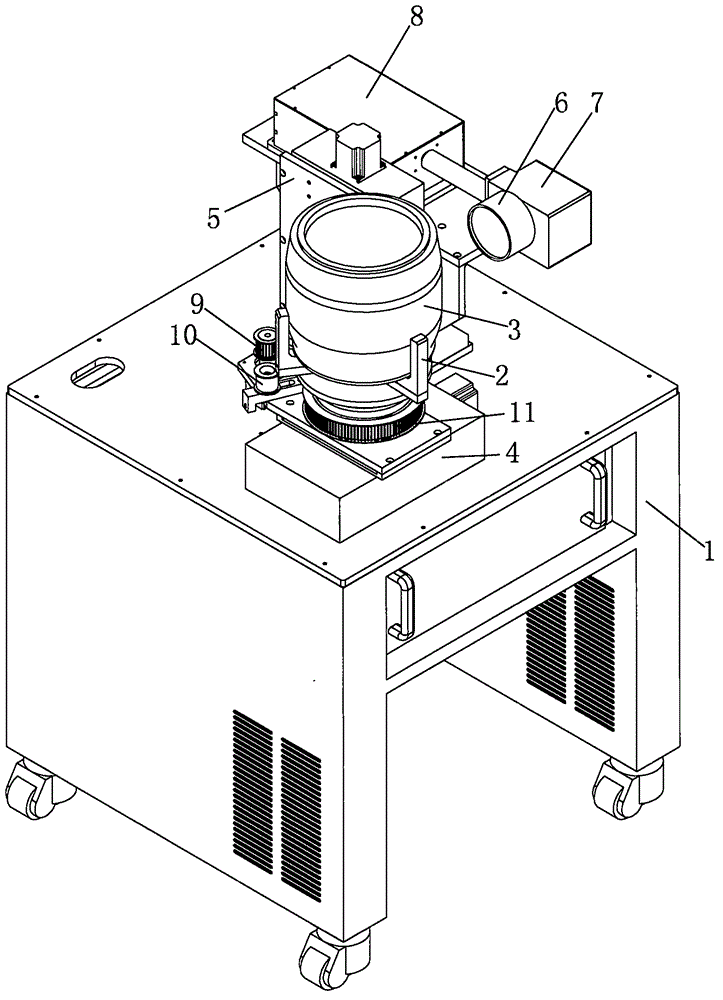

[0029] Embodiment: first define the lower position, the present invention makes the position agreement when the device is placed normally, the plane determined by the X-Y direction is the horizontal plane, the Y direction is the direction in which the moving parts move in the Y direction, that is, the front-to-back direction; the Z direction is the height Direction, that is, the up and down direction; the Y direction moving parts move back and forth to make the laser focus point engrave at different depths of the glass to achieve a three-dimensional engraving effect.

[0030] A method for engraving a three-dimensional image in a glass with a regular arc, including a process of using a laser focusing method to form a damage point in the glass with a regular arc, and also including a process of moving the laser focus in the glass with a regular arc point process, wherein, the distance between the glass and the laser focus point is adjustable, and the glass itself rotates so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com