Fangmu Planer Machine Tool

A technology of plane planing and machine tools for square wood, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., which can solve the problems of low efficiency, labor and time, etc., reduce labor force, solve labor intensity, and save processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

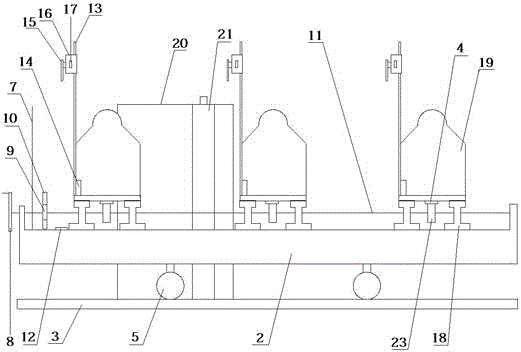

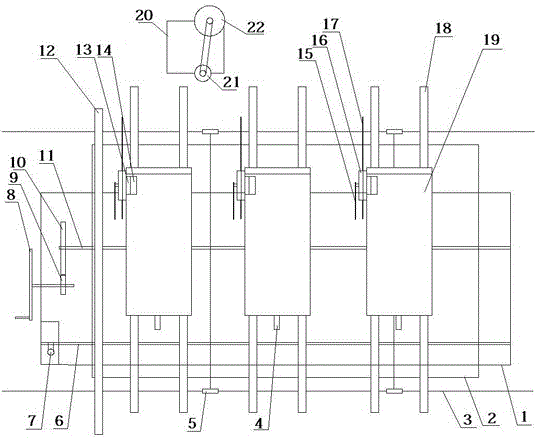

[0027] During processing, the imitation wood that needs processing is placed on the guide rail 18 one sides on the sports car frame 2, and imitation wood contacts with fixed mount 19.

[0028] By turning the hand wheel 8, the driving gear 9 drives the driven gear 10 to rotate, and the driven gear 10 drives the rotating shaft 11 to rotate; the transmission gear 23 on the rotating shaft 11 rotates, and the transmission rack 4 meshed with the transmission gear 23 moves, and the transmission gear 4 is engaged with the transmission gear. The fixed plate 19 that bar 4 is fixed moves, and the movement of fixed plate 19 on the guide rail 18 can regulate the position of imitation wood, selects processing size by scale 12, stops rotating hand wheel 8.

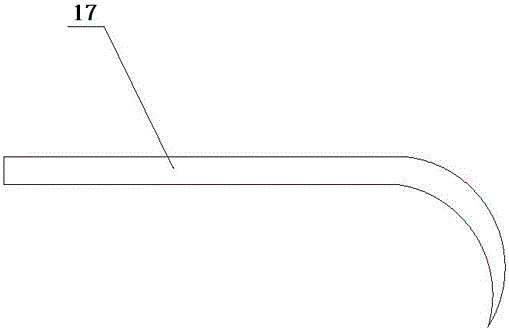

[0029] The fixed claw 17 suspended above the fixed frame 19 contacts with the imitation wood, and the fixed claw 17 is blocked by the clamping assembly 16 and the clamping handle 15 to prevent the imitation wood from shifting during proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com