Floating pin self-locking device for tunnel core-pulling mechanism

A technology of tunnel core-pulling and self-locking device, applied in the field of molds, can solve the problems of increasing the complexity of the mechanism, the difficulty of controlling the movement sequence, the disorder of the movement sequence, and the damage to plastic products, etc., so as to achieve the simple and easy operation of the self-locking device and the production efficiency Elevate and connect rigorous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

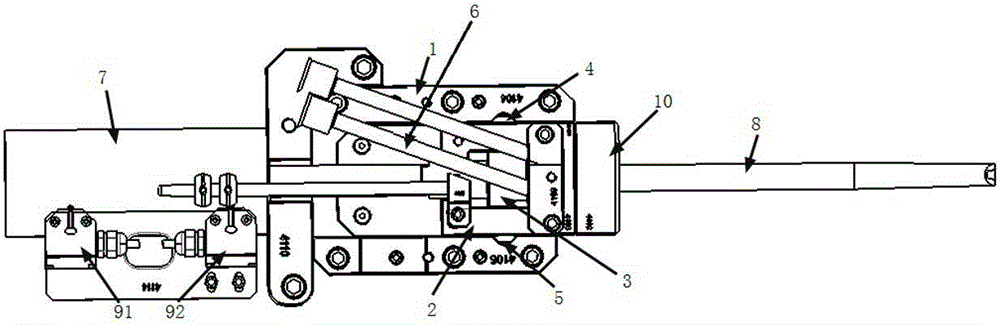

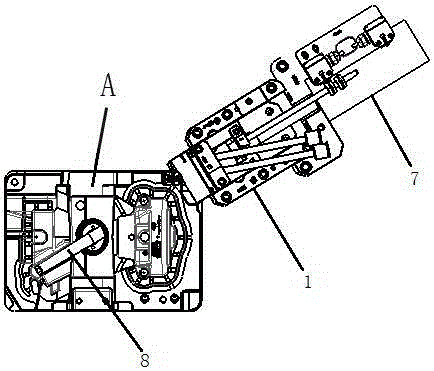

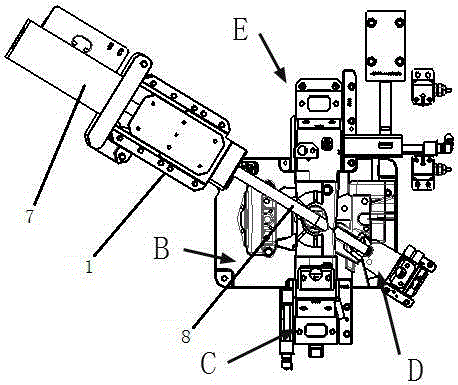

[0016] like figure 1 As shown, a floating pin self-locking device for a tunnel core-pulling mechanism includes a device body 1, a row seat 2 is arranged in the device body 1, and a medium 3 is provided in the row seat 2; the medium 3 The first floating pin 4 and the second floating pin 5 are arranged on both sides, and one end of the medium 4 is connected with a driving mechanism 7; the row position seat 2 is fixedly connected with a tunnel long needle 8, and the tunnel long needle 8 is located away from One end of the drive mechanism 7; the drive mechanism 8 is an oil cylinder; the oil cylinder transmits signals to control movement through the first induction sensor 91 and the second induction sensor 92; the long tunnel needle 8 is connected to the row seat 2 through the insert 10 Above; the travel seat 2 is connected to the device body 1 through a limit rod 6 ; the length of the limit rod 6 is smaller than the length of the device body 1 . In specific implementation, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com