Specially-shaped compound bag die-cutting machine

A composite bag and die-cutting machine technology, applied in container manufacturing machinery, paper/cardboard containers, box making operations, etc., can solve problems such as low work efficiency and high noise, and achieve improved production efficiency, low noise, and smooth movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

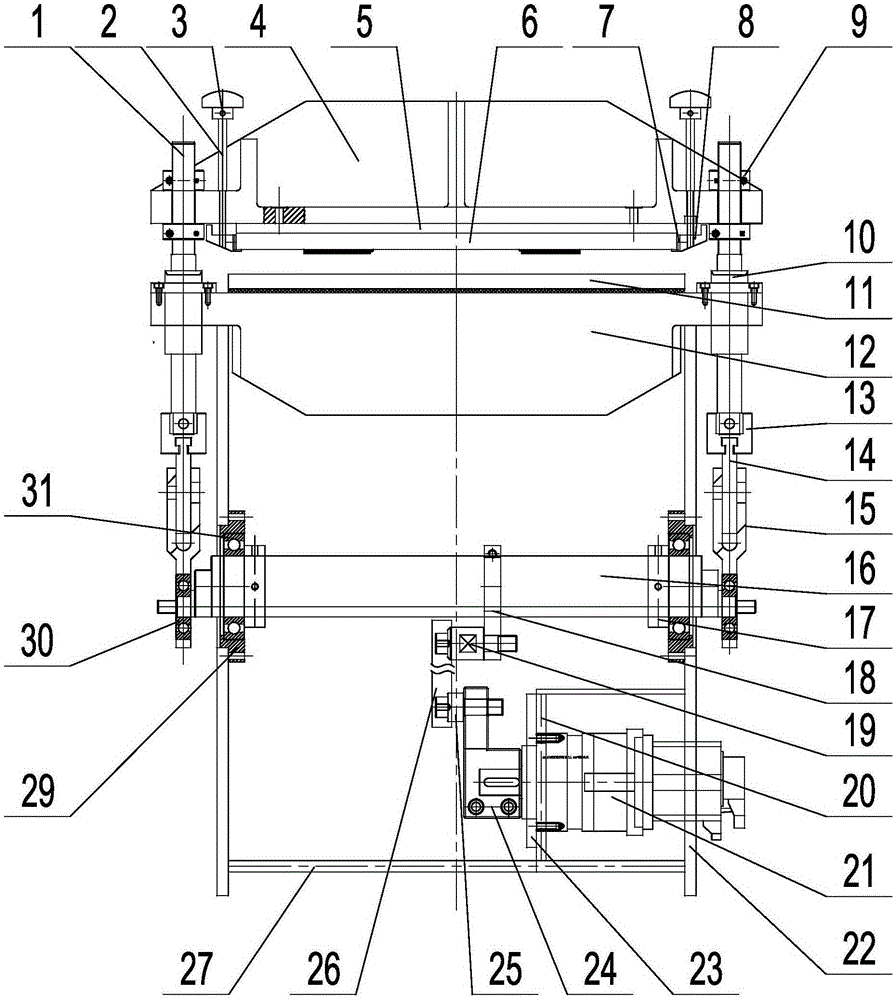

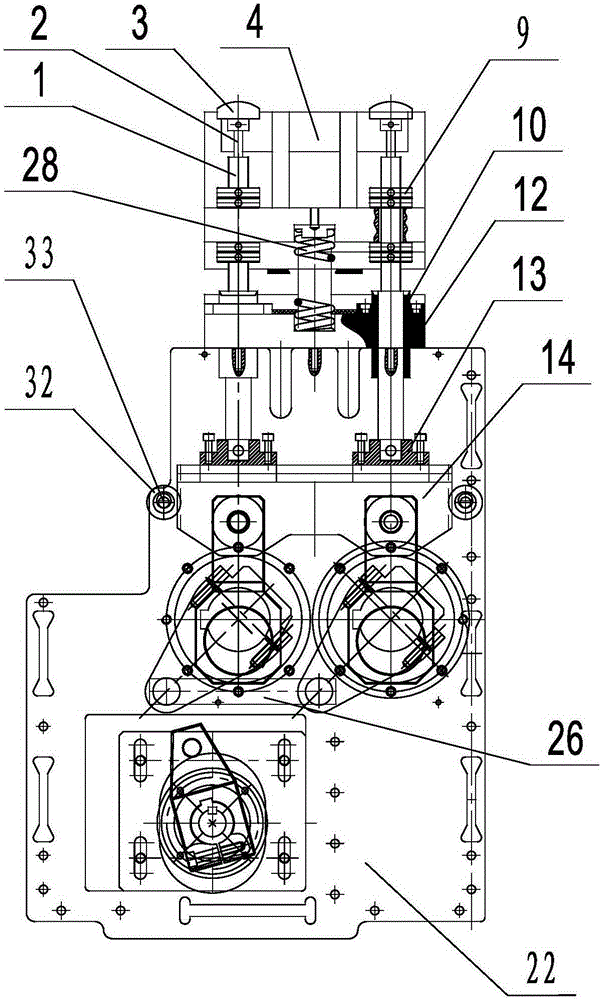

[0017] As shown in the figure: the special-shaped composite bag die-cutting machine in the embodiment is mainly composed of a guide shaft 1, a screw rod 2, an adjustment cap 3, an upper mold base 4, a knife plate 5, a cutter 6, a knife plate 7, a knife holder 8, and a nut 9. Guide sleeve 10, pressure plate 11, lower mold base 12, slider 13, guide plate 14, lifting U-shaped fork 15, eccentric shaft 16, tight ring 17, swing arm 18, first pile head shaft 19, motor bracket 20 , servo motor 21, wall plate 22, motor fixing seat 23, eccentric arm 24, second pile head shaft 25, connecting plate 26, bottom plate 27, spring 28, bearing seat 29, small bearing 30, large bearing 31, positioning bearing 32 And components such as eccentric minor shaft 33 are formed.

[0018] Such as figure 1 , figure 2 As shown, the lower mold base 12 is fixedly installed on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com