Heavy-duty shuttle wheel side drive system integrating differential transfer and wet brake

A drive system, wet brake technology, applied in the direction of the transmission device driven by the electric motor, can solve the problems of poor steering differential function, large braking impact, etc., achieve small braking impact, high power utilization, and reduce control requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

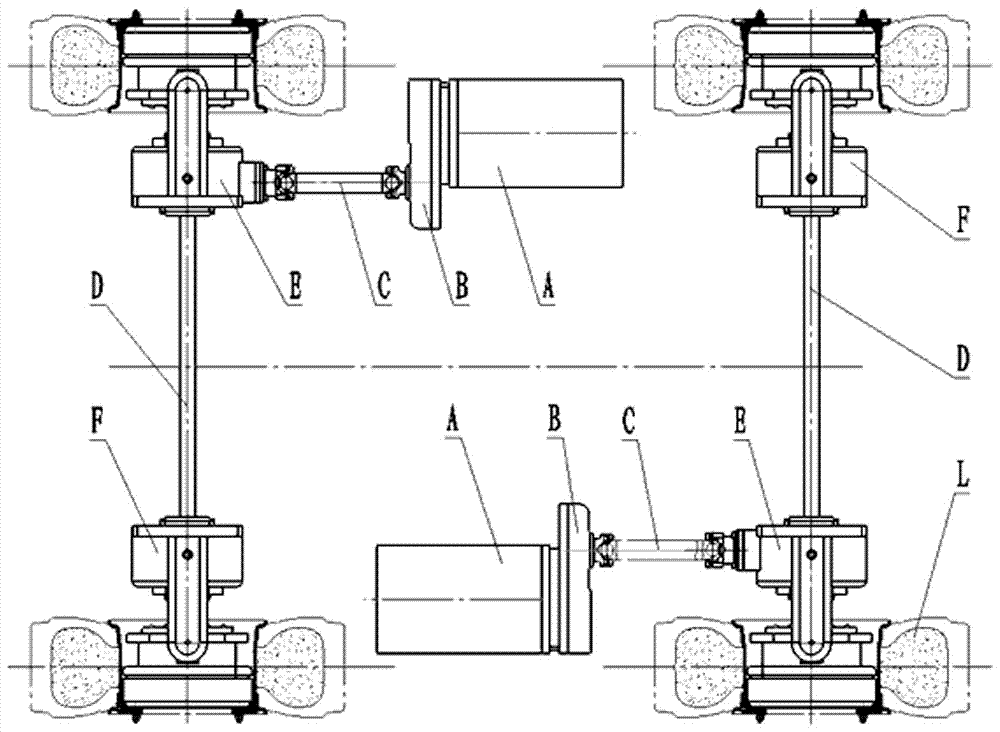

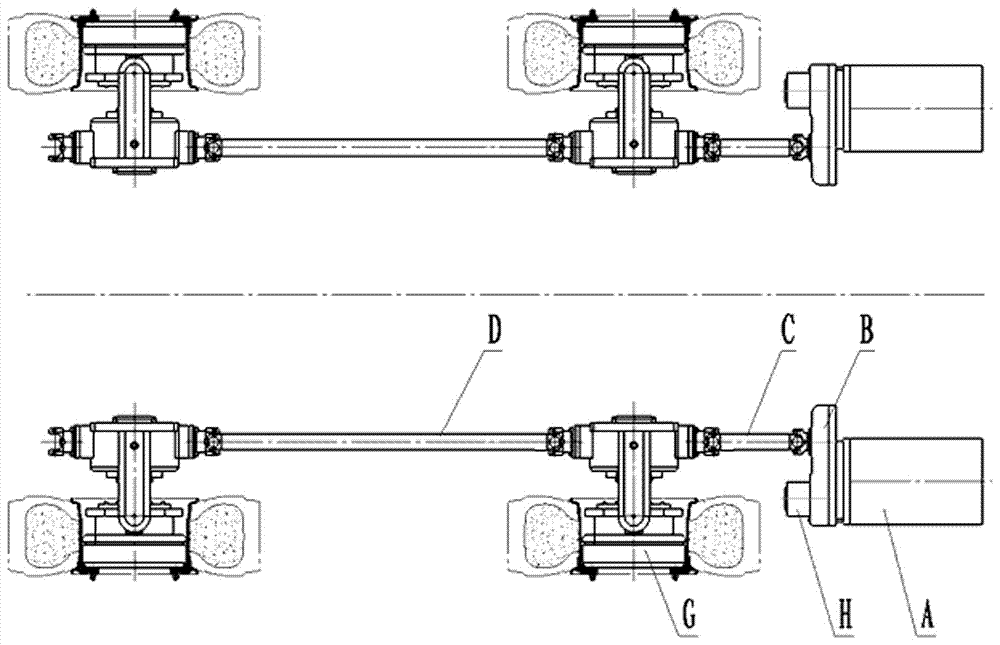

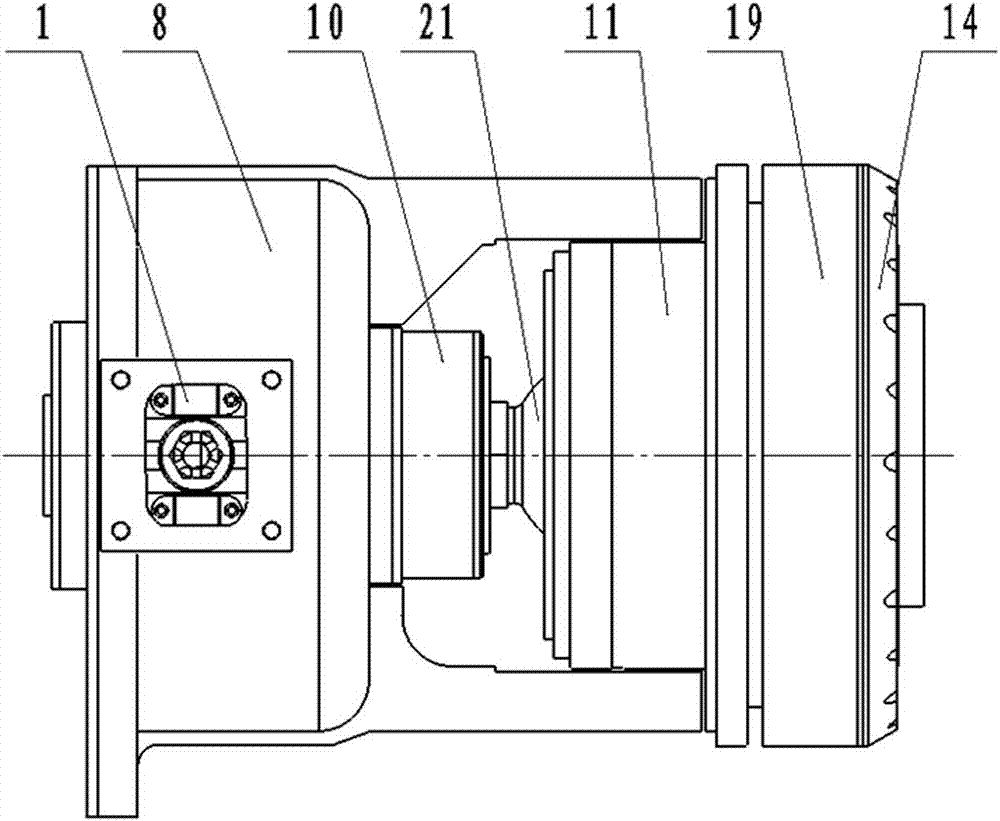

[0029] The present invention is mainly used in mine conditions of medium-thick coal seams, and is applied to heavy-duty shuttle cars (shuttle cars of 20t and above) with larger body height and width. Such as figure 1 As shown, the driving front axle and the driving rear axle of the shuttle car are driven / braked separately, that is, parallel control, and are respectively controlled by the drive system of the present invention. The drive system includes a motor A, a primary speed reducer B, a wheel edge Reducer IE and wheel reducer IIF, wheel reducer IE and wheel reducer IIF are symmetrically installed at both ends of the transverse drive shaft D of the corresponding shuttle car drive axle, and wheel reducer IE and wheel reducer IIF are located at On the inner side of the running rubber wheel L of the shuttle car, the wheel side reducer IE is connected to the output end of the first-stage reducer B through the transmission shaft C, and the first-stage reducer B is driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com