Lightweight automotive middle channel

A lightweight, mid-channel technology, applied in vehicle components, superstructure, and sub-assembly of the upper structure, etc., can solve the problems of increasing the weight of the whole vehicle, weak joints, fractures, etc., to ensure strength and rigidity, reduce weight, and ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

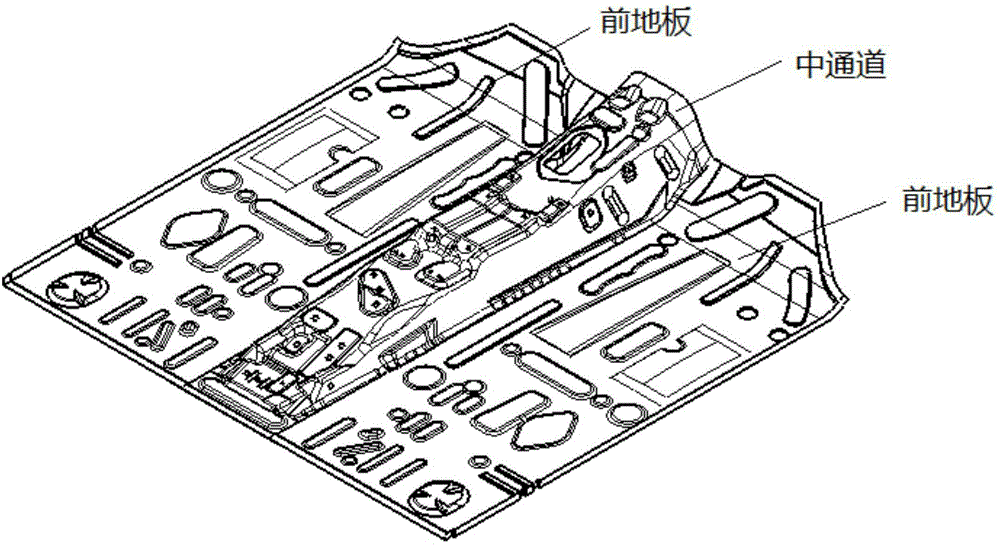

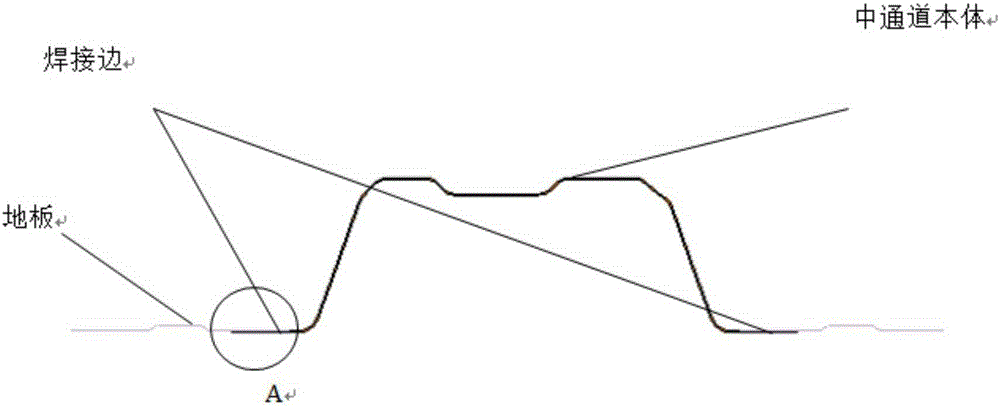

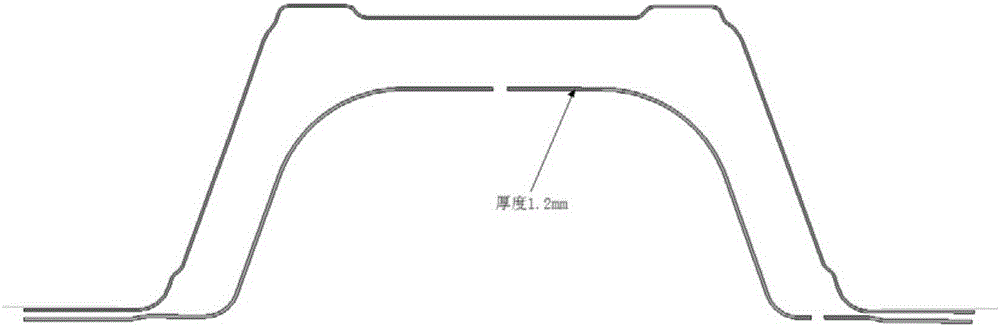

[0029] Embodiment of the present invention is a kind of passageway in lightweight automobile, please refer to Figure 4 , is a cross-sectional view of the middle passage in the embodiment of the present invention, the longitudinal section of the middle passage 1 is a few characters, and the two sides of the middle passage 1 are respectively connected with the front floor 2 of the car, and the front floor 2 includes the front floor main body, The front floor front crossbeam and the front floor rear crossbeam, the two ends of the front floor front crossbeam and the front floor rear crossbeam are respectively connected to the door sill and the middle channel of the car. Wherein, the front floor 2 is arranged under the middle passage 1, and the two sides of the middle passage 1 are provided with flanges, and the front floors 2 on both sides of the middle passage respectively extend to the middle of the middle passage 1 and form cavities 3 with the middle passage 1 respectively. , ...

Embodiment approach 2

[0033] see Figure 5 , the difference from Embodiment 1 is that in this embodiment, the two ends of the middle channel 1 are respectively welded to the corresponding front floor 2, so that the cavity 3 forms a sealed cavity, and in the The channel 1 or the front floor 2 is provided with a valve core 13 communicating with the sealed cavity, and the sealed cavity is evacuated by a vacuum device to form a negative pressure cavity.

[0034] In this embodiment, the cavity formed by the middle passage and the front floor is welded into a sealed cavity, and the air inside is removed to form a negative pressure cavity, so that the effect of atmospheric pressure is used to improve the connection between the middle passage and the front floor. The overall strength between the front floors improves the structural strength of the center channel without changing the structure of the center channel or adding any weight. Tests have proved that the negative pressure cavity improves the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com