A thermal insulation storage type asphalt pavement comprehensive maintenance vehicle

A technology for asphalt pavement and maintenance vehicles, which is applied to roads, roads, road repairs, etc., can solve the problems of reducing labor intensity of workers, large heat exchange area, low heating efficiency, etc., and achieves high construction efficiency, large heat exchange area, and output No card material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

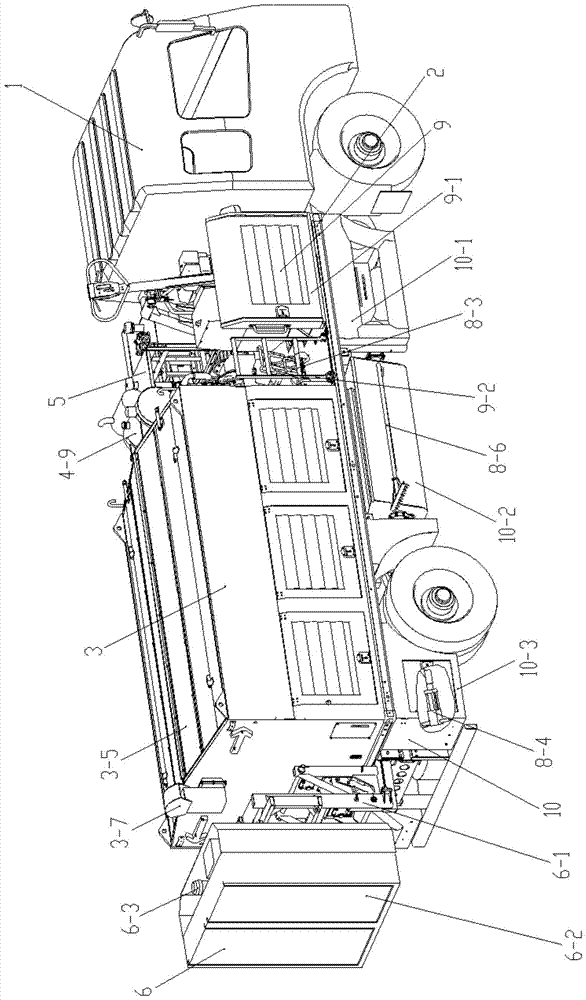

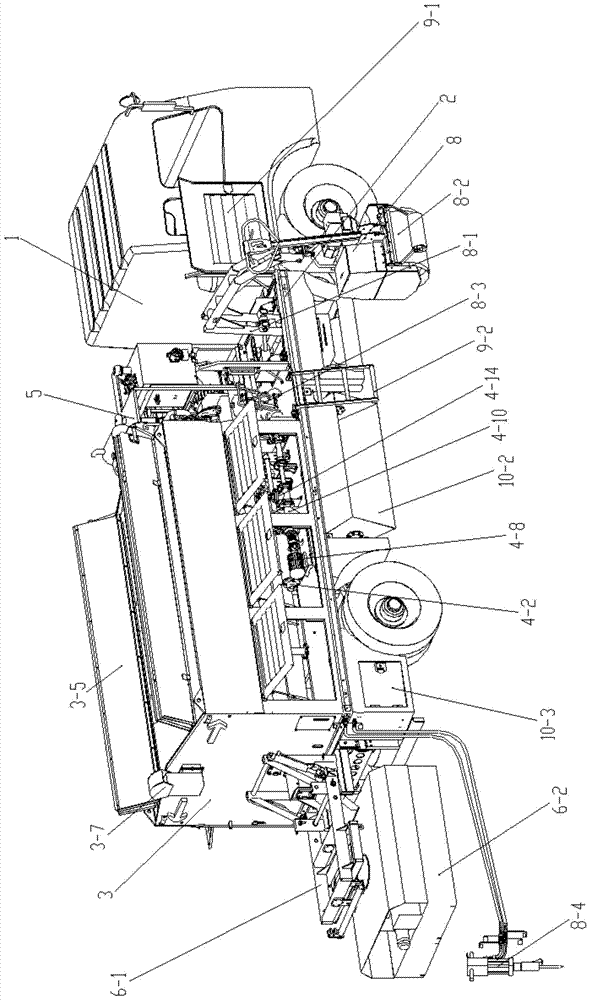

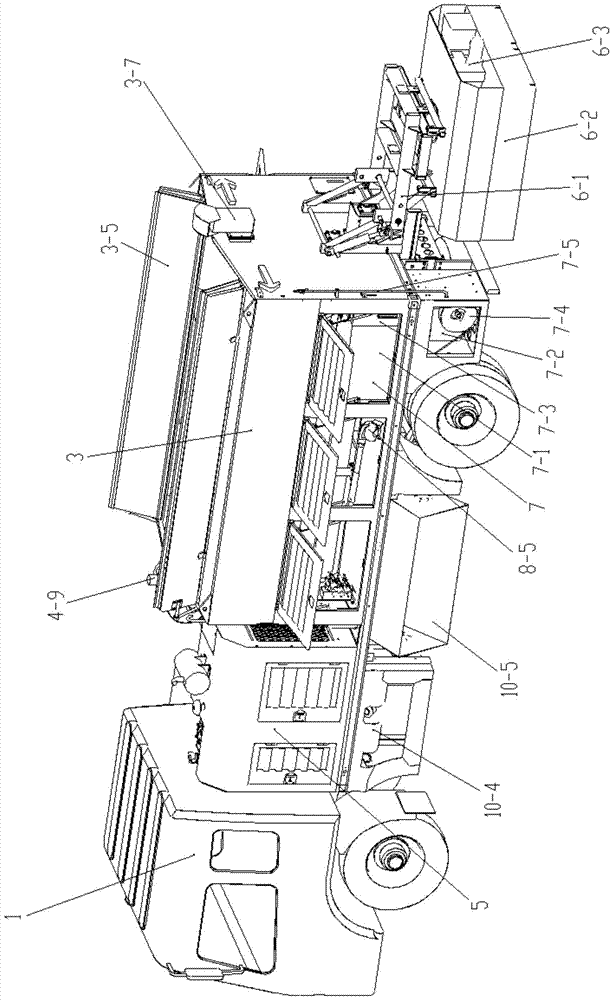

[0032] Such as Figure 1 to Figure 7 As shown, a kind of thermal insulation storage type asphalt pavement comprehensive maintenance vehicle of the present invention includes automobile chassis 1, vehicle frame 2, thermal insulation silo 3, heating system 4, generator set 5, heating wall system 6, emulsified asphalt system 7, Auxiliary tool 8, surrounding 9 and getting off protection 10.

[0033] The frame 2 is fixed on the support beam of the automobile chassis through the U-shaped screw, the upper and lower connecting blocks, and the thrust plate. The thermal insulation silo 3, the heating system 4, the generator set 5, the emulsified asphalt system 7, and the auxiliary tools 8 are fixed on the frame 2 The heating wall system 6 is set on one side of the thermal insulation silo 3, and the upper enclosure 9 and the getting off protection 10 are respectively set above a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com