Sliding door plate and sliding door with sliding door plates

A sliding door and door panel technology, which is applied in the direction of door leaf, door/window fittings, wing leaf arrangement, etc., can solve the problems of difficulty in realizing the exchange of left door and right door, and difficulty in realizing push-pull action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

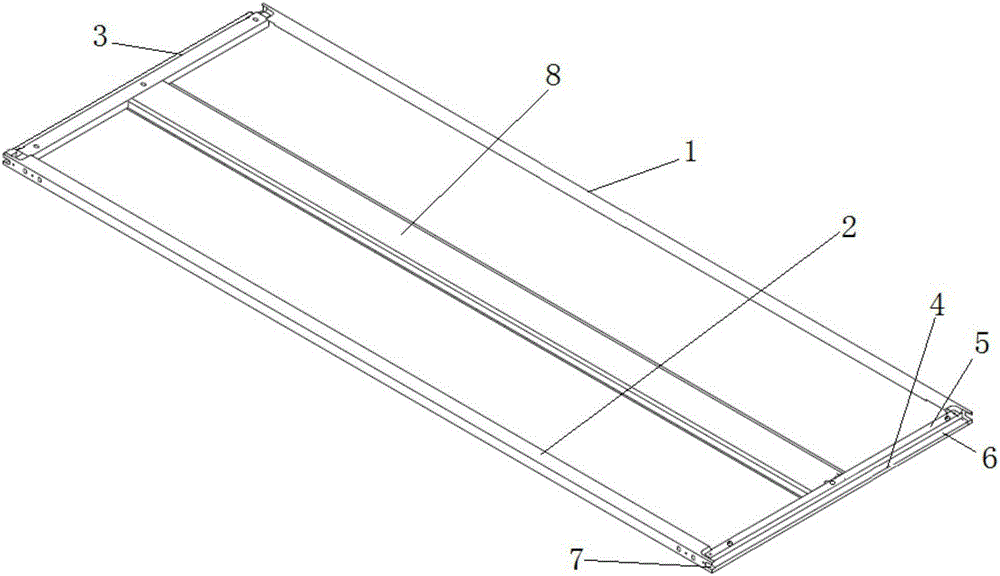

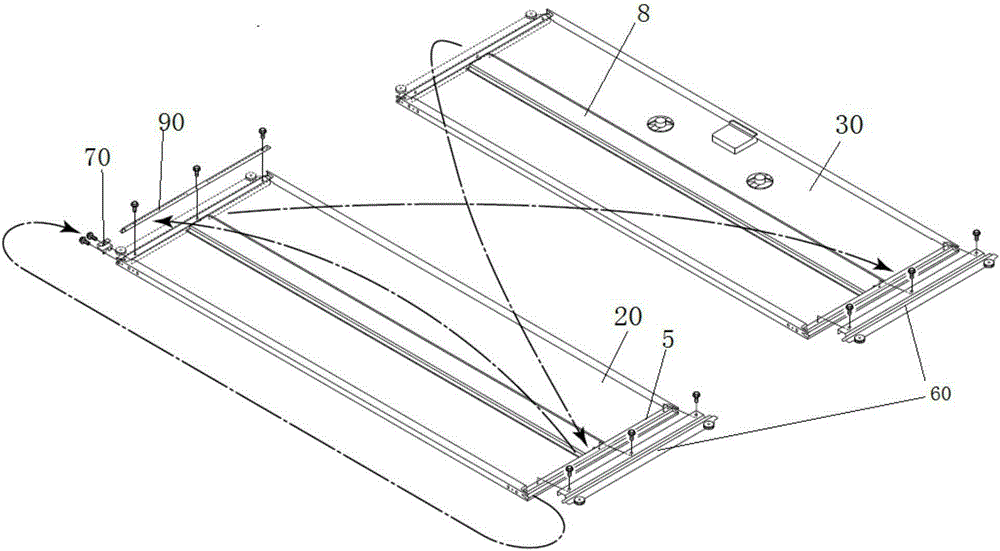

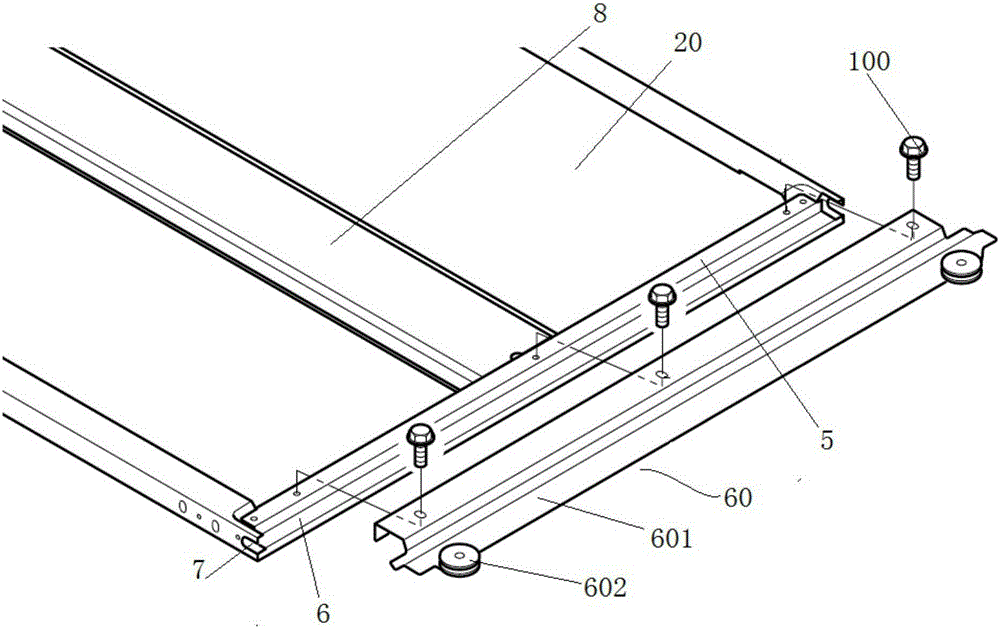

[0029] Such as figure 1 As shown in the structure, the present invention provides a sliding door panel. The door panel is formed by bending a steel plate, and its left and right sides are bent to form a symmetrical left panel frame 1 and a right panel frame 2, and its upper and lower ends are bent. A symmetrical upper frame 3 and a lower frame 4 are formed, and a convex structure 5 parallel to the surface of the door panel is respectively formed on the upper frame 3 and the lower frame 4, and a plurality of screw holes are formed at intervals along the length of the convex structure 5 . Because the upper plate frame 3 and the lower plate frame 4 are symmetrical, and the left plate frame 1 and the right plate frame 2 are symmetrically ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap