a centrifugal pump

A technology of centrifugal pumps and front pumps, applied in the field of centrifugal pumps, which can solve problems that do not involve improving the flow characteristics inside the front chamber, and achieve the effects of weakening disturbances, improving working conditions, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

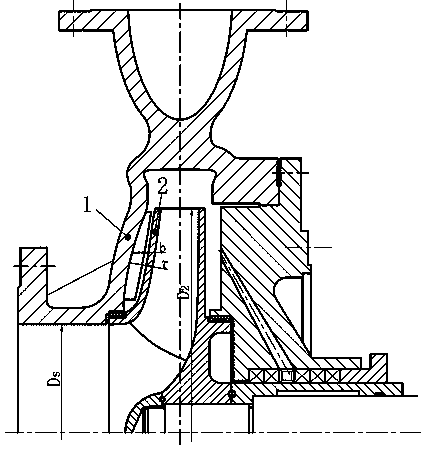

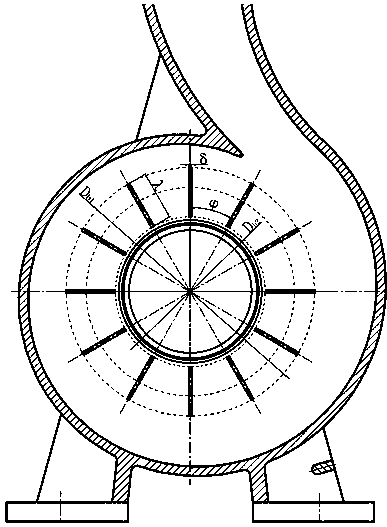

[0017] In the present invention, taking a centrifugal pump as an example, 12 annular blades are arranged inside the front pump cover of the volute, such as figure 2 shown. The angle φ between two adjacent front blades is determined by the number of blades Z, which is 360° / Z. In this example, Z is 12 pieces, then φ=30°; the inlet diameter of the front blades is D b1 According to formula D b1 =(0.95~1)×D2, determined by the impeller outer diameter D2, in this example D2=240 mm, D b1 =228mm, the outlet diameter D of the front blade b2 by D b2 =(1.1~1.3)×Ds, Ds is impeller inlet diameter, in this example D b2 =140mm. Such as figure 1 As shown, the diameter of the outlet of the front blade is above the mouth ring, and the meridian section of the front cavity shrinks rapidly; the length of the front blade λ=(D b1 -D b2 ) / 2, in this example λ=44 mm. The height of the front blade changes due to the change of the geometric structure of the front cavity. The gap τ between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com