Patents

Literature

35results about How to "Reduce vortex intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

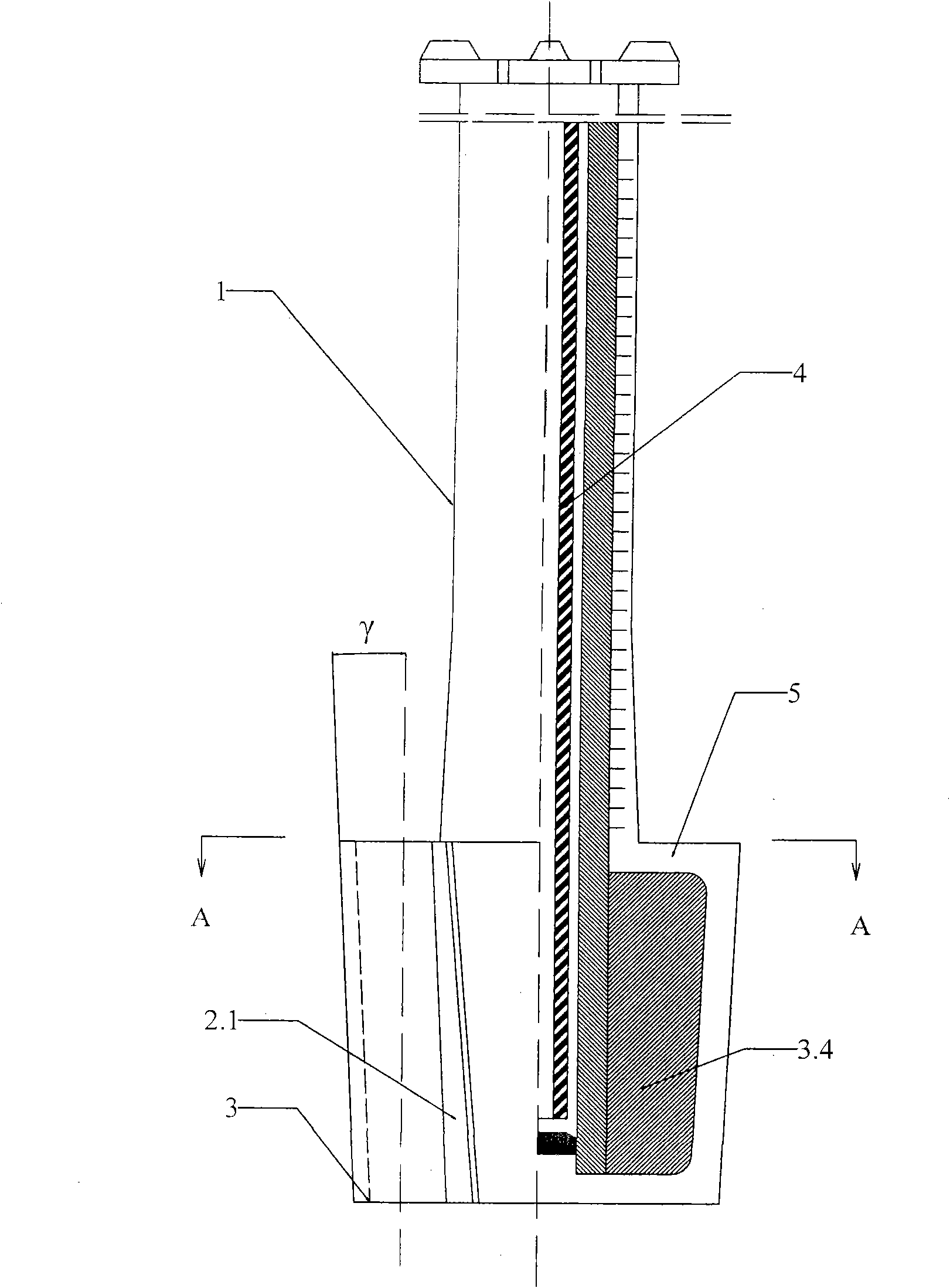

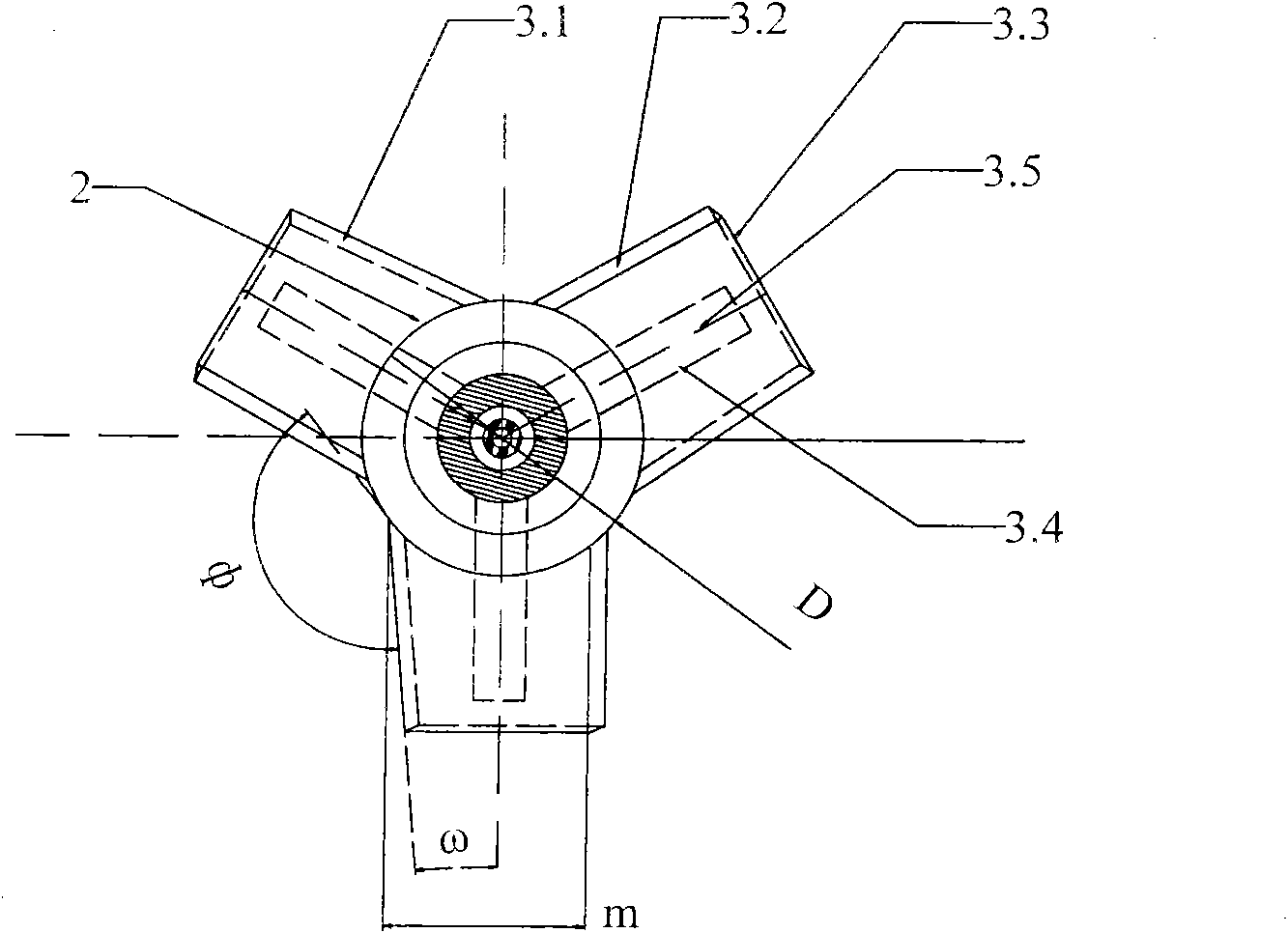

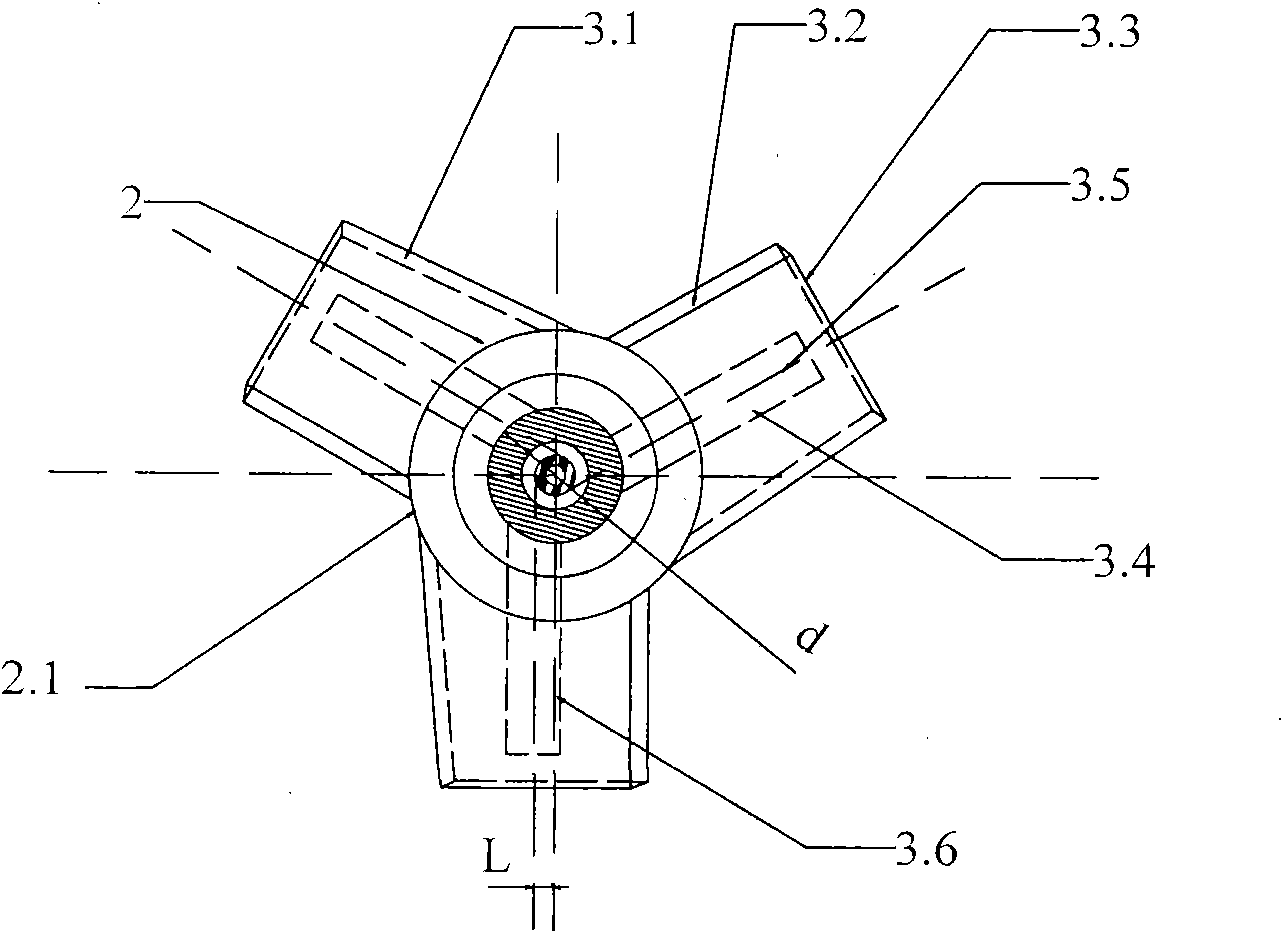

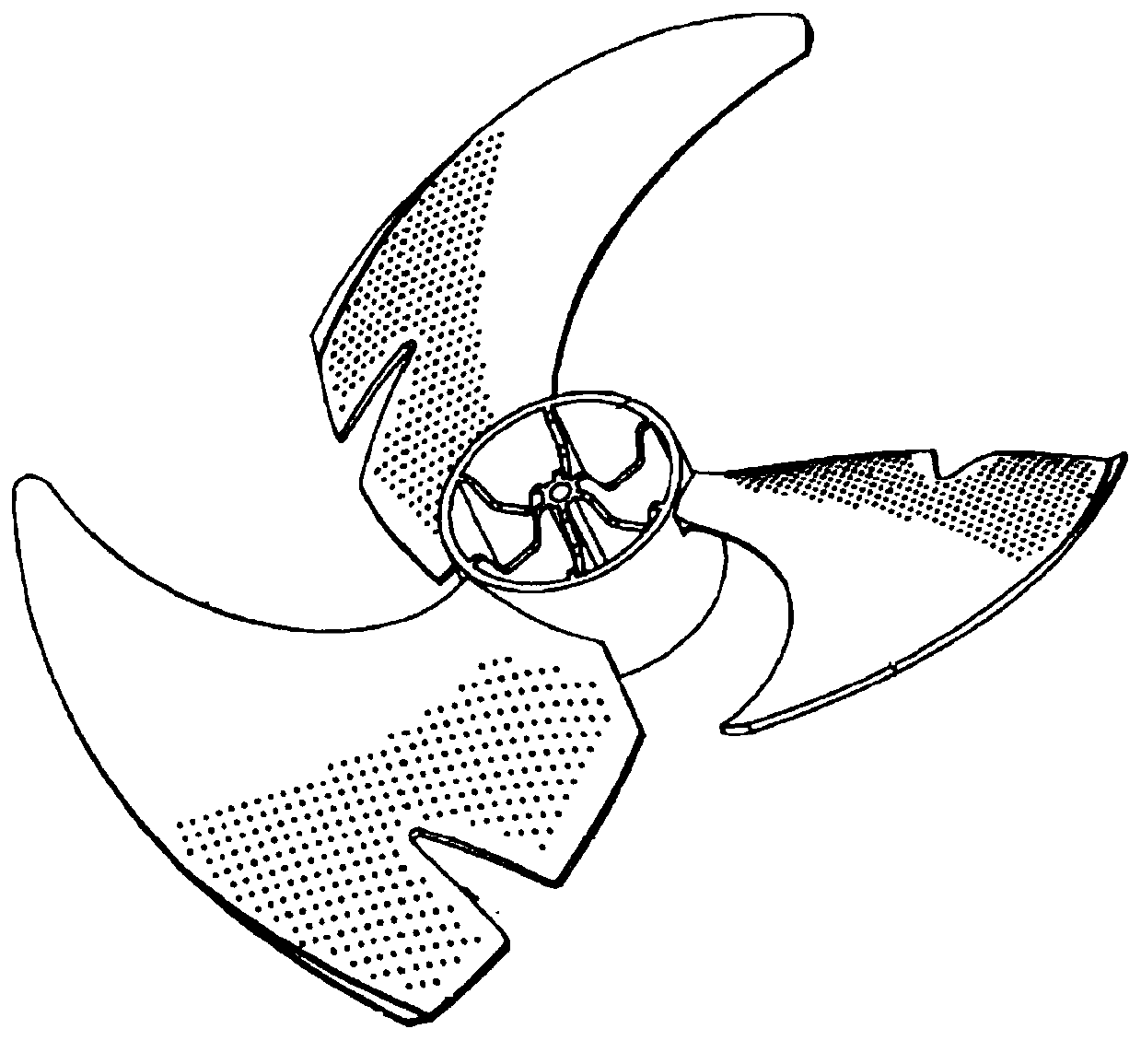

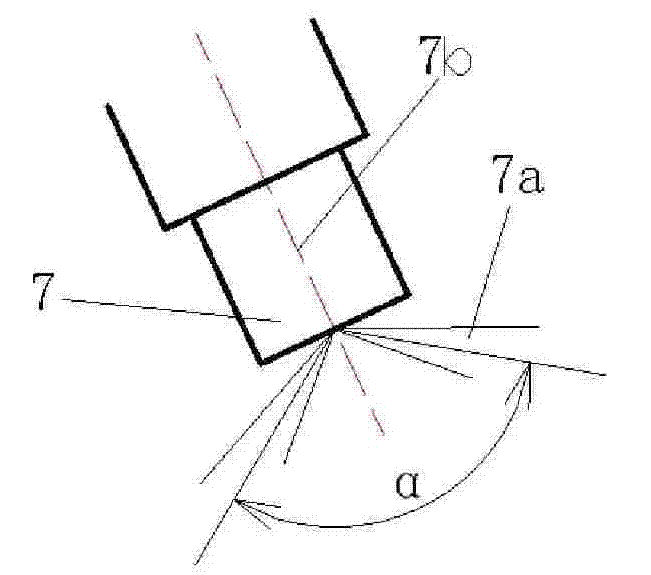

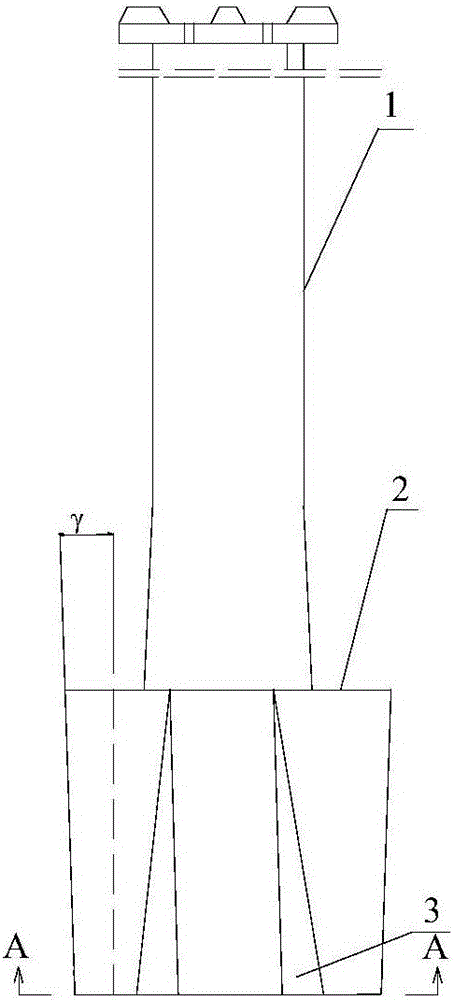

Turbine type stirrer used for molten iron mechanical stirring desulfuration

The invention discloses a turbine type stirrer used for molten iron mechanical stirring desulfuration, comprising a rotating shaft, a wheel hub and three stirring vanes, wherein, each stirring vane comprises a stirring vane metal core and is evenly distributed at the periphery of the wheel hub; the surface facing melt iron, the surface deviating melt iron and the side face of the stirring vane are all inclined planes inclining forwards from bottom to top, and the angles of inclination alpha, beta and gamma respectively satisfy the following conditions: alpha is more than or equal to 1 degree and less than or equal to 10 degrees, beta is more than or equal to alpha and less than or equal to 15 degrees, and gamma is more than or equal to 0 degree and less than or equal to 3 degrees; the stirring vane metal core is in eccentric arrangement; the flat surface on which the thickness symmetry plane of the stirring vane metal core is located is a first vertical plane; the flat surface parallel to the first vertical plane and passing the centre line of the rotating shaft is a second vertical plane; the first vertical plane is overlapped with the second vertical plane horizontally moving a distance of L towards the direction of the surface facing melt iron, wherein, L satisfies the condition that L is more than 0 and less than or equal to (d-a) / 2; d is the diameter of the metal core of the rotating shaft; and a is the thickness of the stirring vane metal core; by applying the invention, the stirring power consumption of the invention is low, the sticky dregs between the stirring vanes are less; and the dynamical condition of stirring desulfuration is good.

Owner:武钢集团有限公司

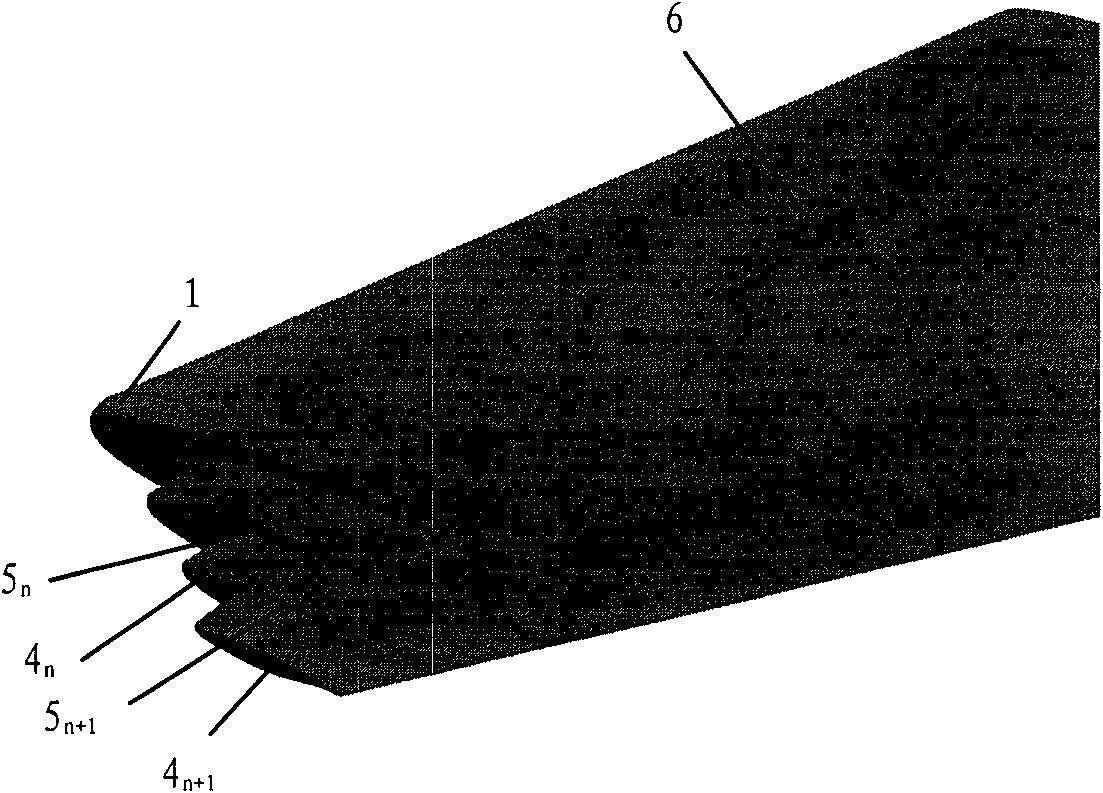

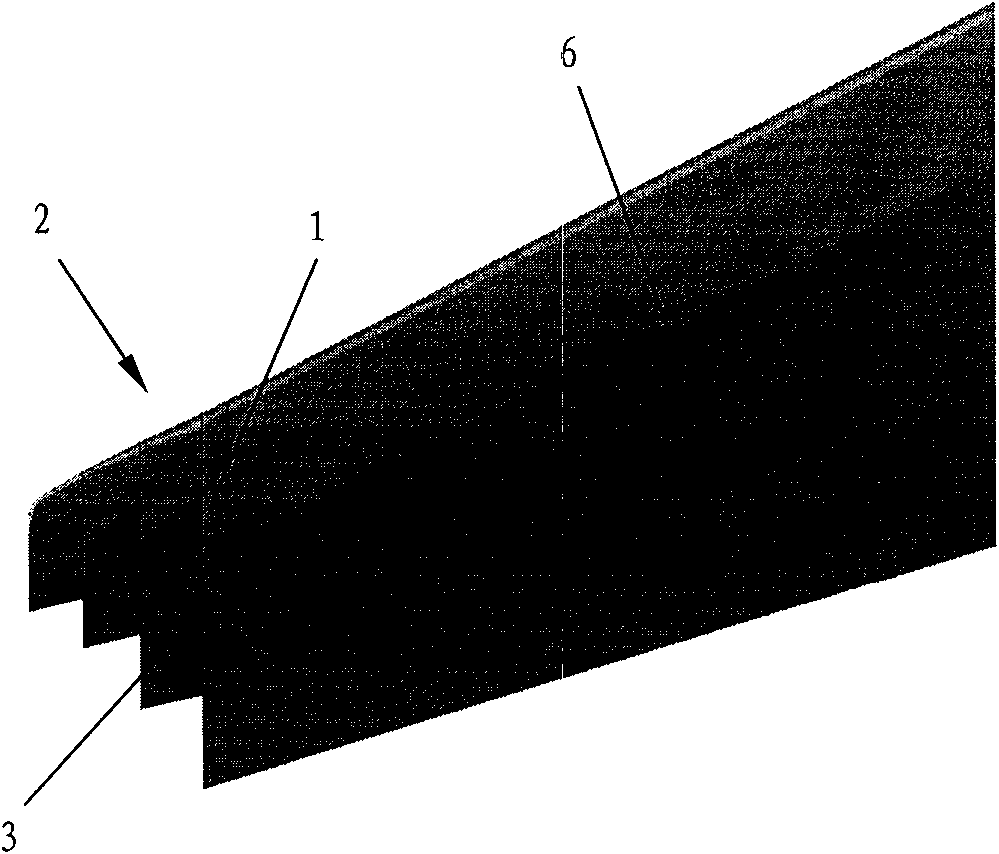

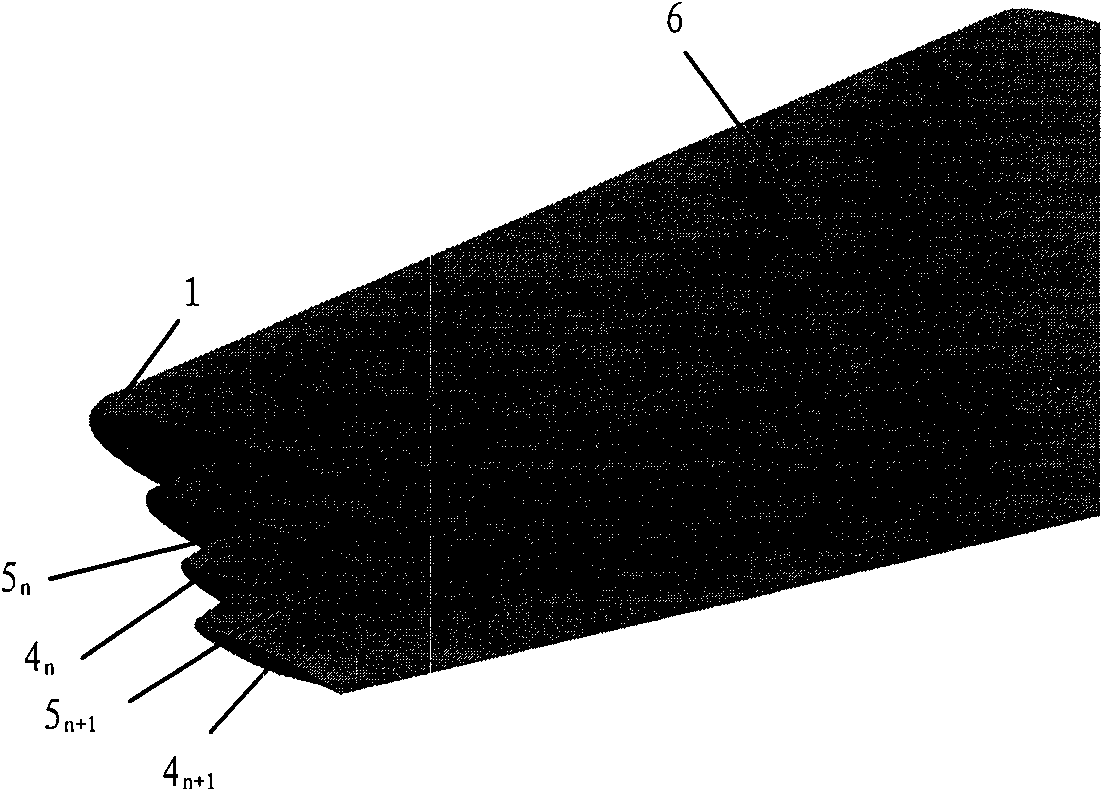

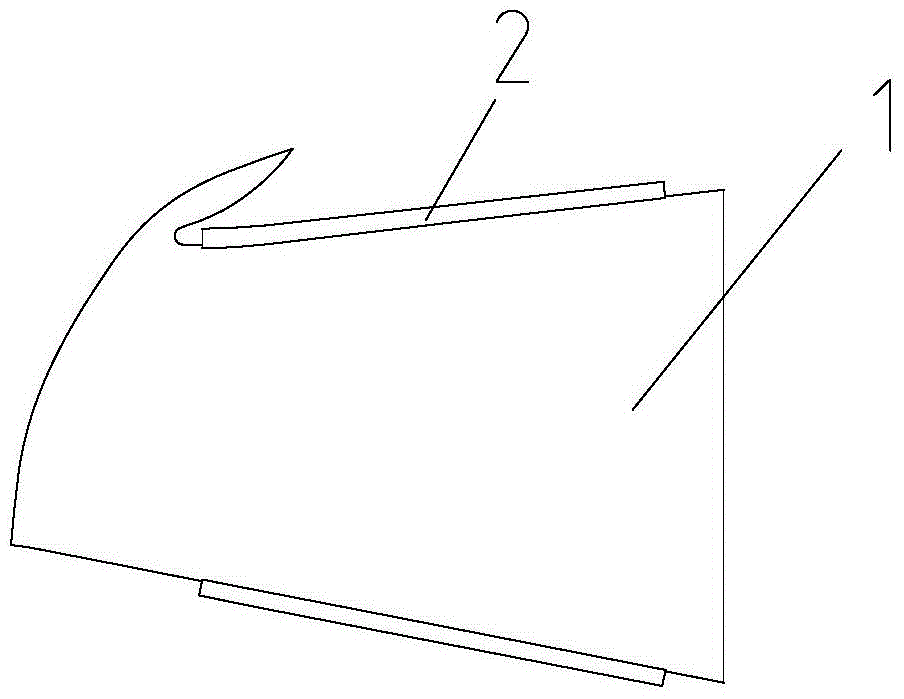

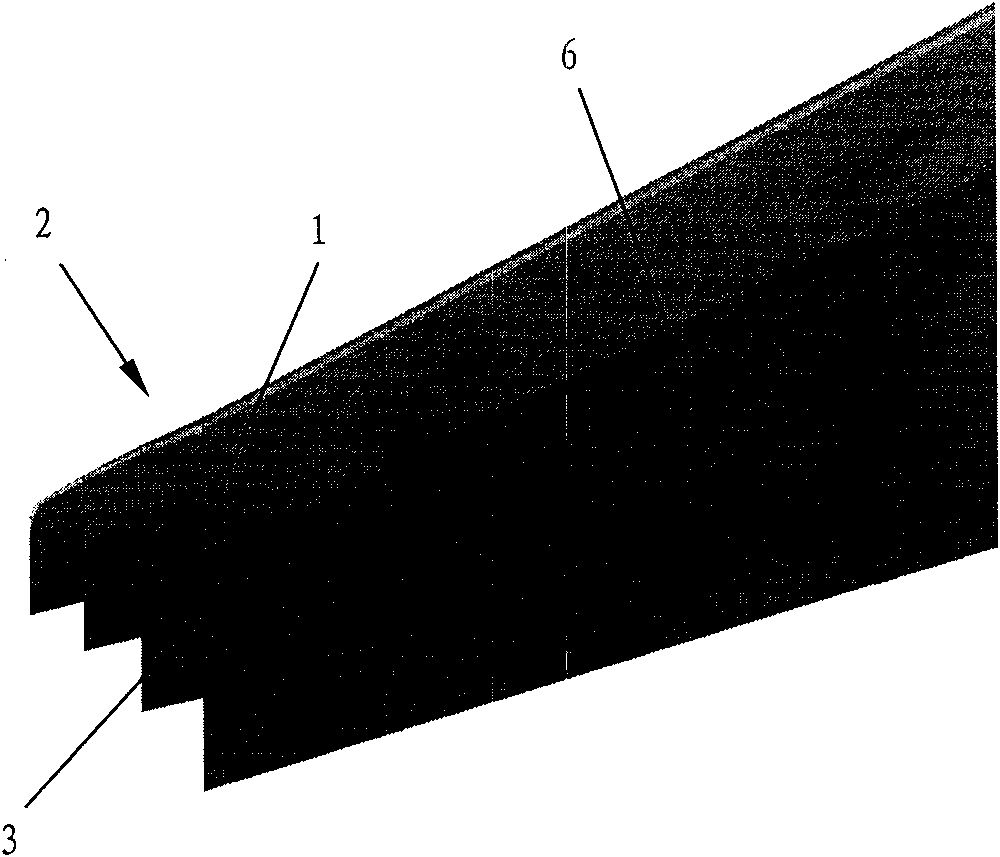

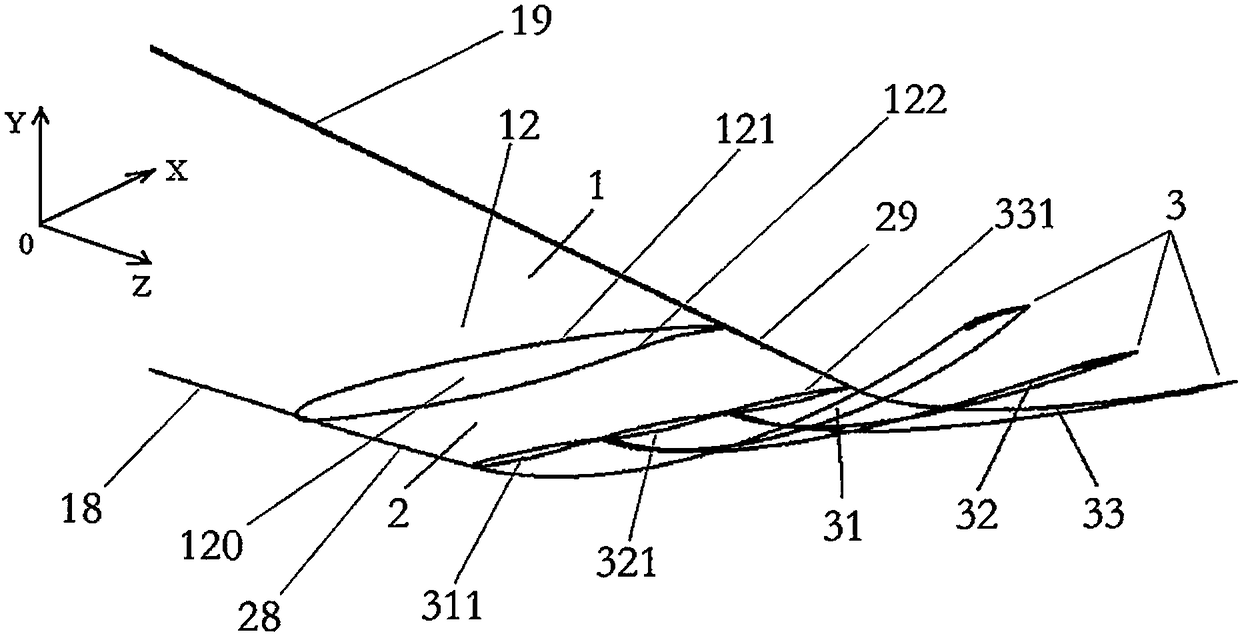

Airplane wingtip device with aligned front edge

ActiveCN102167152ASmall bending moment incrementReduce structural weightWing shapesDrag reductionWingtip deviceFront edge

The invention provides an airplane wingtip device with an aligned front edge, which comprises a transition part and a wingtip part, wherein the inside end of the transition part is connected with the far end of an airplane wing, the outside end of the transition part is connected with the wingtip part, the wingtip part comprises a plurality of wingtip segments, each wingtip segment comprises a wingtip and a wing root, the wing root of the first wingtip segment is connected with the outside end of the transition part and is aligned with the front edge at the outside end of the transition part, the wing root of the (n+1)th wingtip segment is arranged on the wingtip of the nth wingtip segment, and the wing root chord length of the (n+1)th wingtip segment is less than or equal to the wingtip chord length of the nth wingtip segment, wherein n is more than 0. The wingtip device is step-shaped, so that each wingtip is additionally provided with at least one of discontinuity surfaces, the wingtip vortexes induced by the wingtips are restrained with one another, and the vortex intensity is reduced, therefore the airplane wingtip device achieves a damping effect; and the bending moment incremental quantity of each wing root is less, so that the structural weight of the airplane is reduced, and the influence on the buffeting characteristic is less.

Owner:COMAC +1

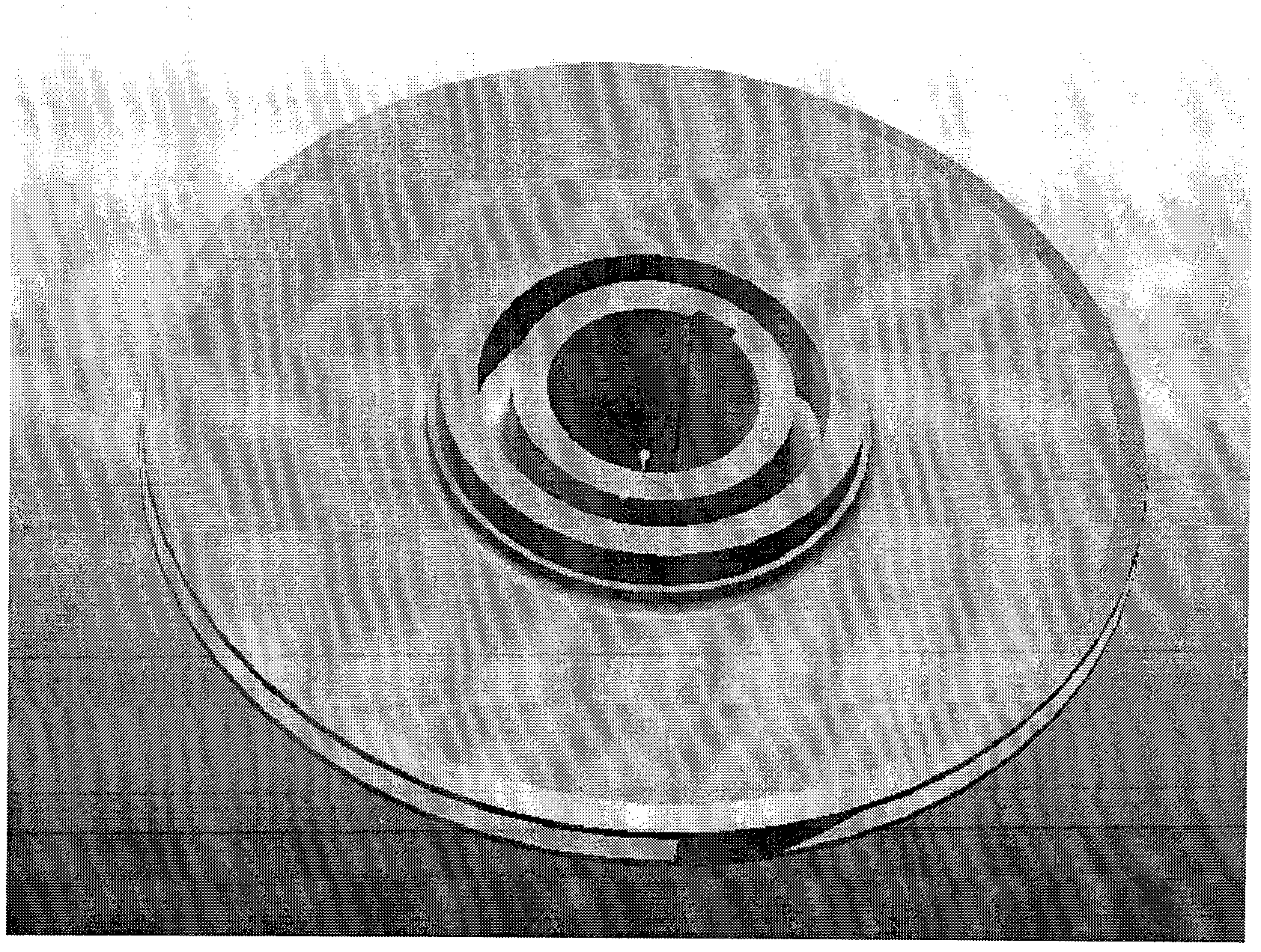

Low specific speed impeller with function of drag reduction by grooves

InactiveCN103195744AReduce roughnessReduce vortex intensityPump componentsPumpsImpellerThree phase asynchronous motor

The invention relates to a low specific speed impeller with the function of drag reduction by grooves. The low specific speed impeller provided with a dry three-phase asynchronous motor or a submersible motor is characterized in that series of grooves are made on pressure surfaces and suction surfaces of blades by machining or casting, and the grooves are 60-degree and 2-4mm in depth. The low specific speed impeller has the advantages that vortexes in an impeller passage are less strong, surface turbulent energy loss is reduced for the low specific speed impeller, and positive effects on improving the efficiency of a low specific speed pump, saving energy, absorbing shock and reducing noise are achieved.

Owner:JIANGSU UNIV

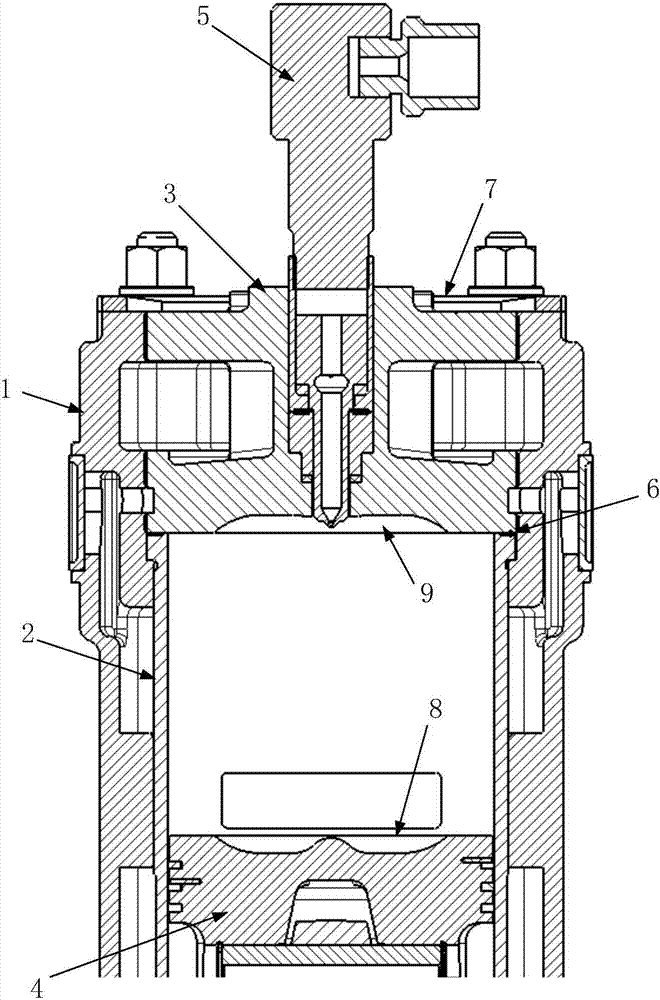

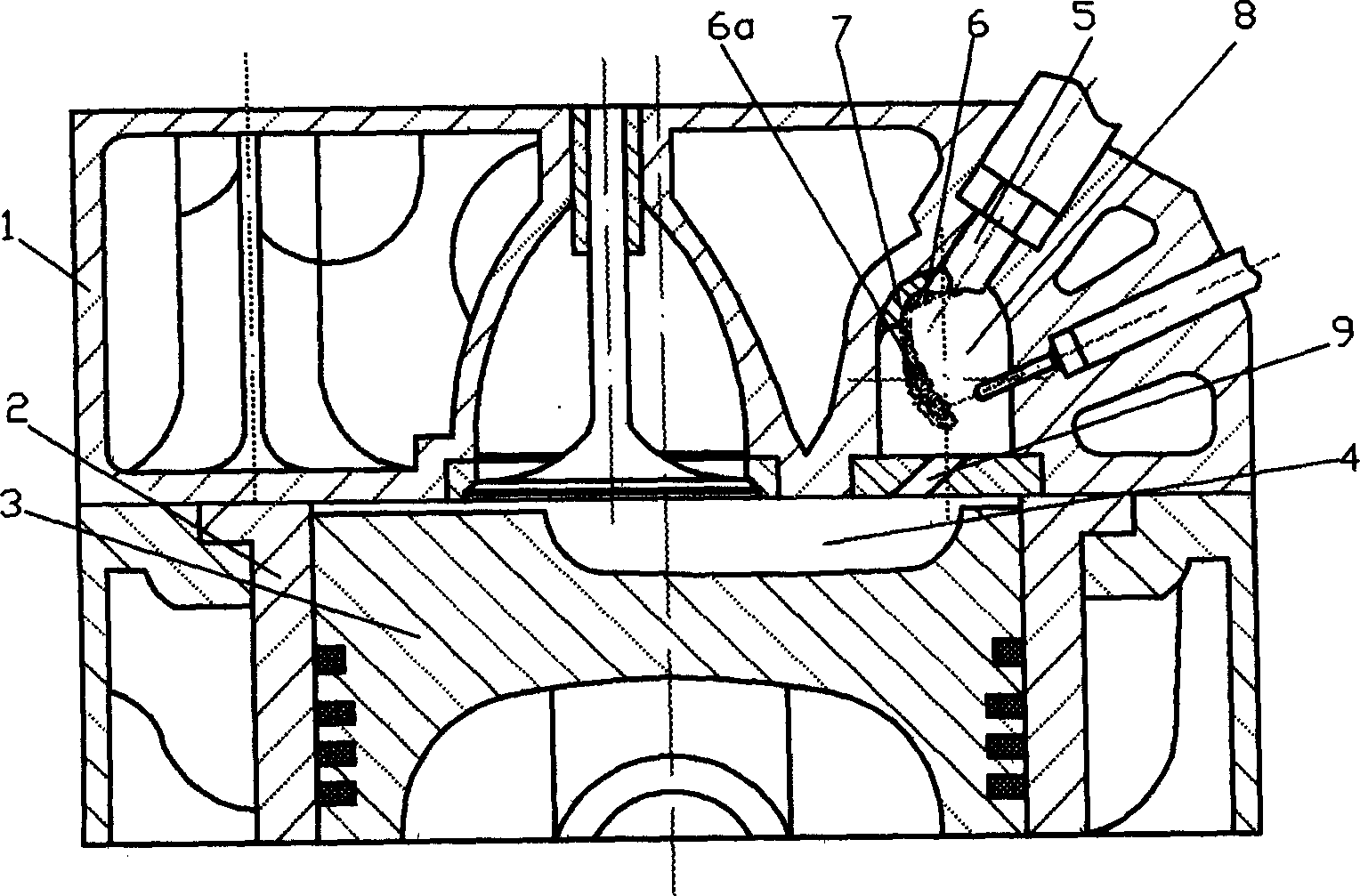

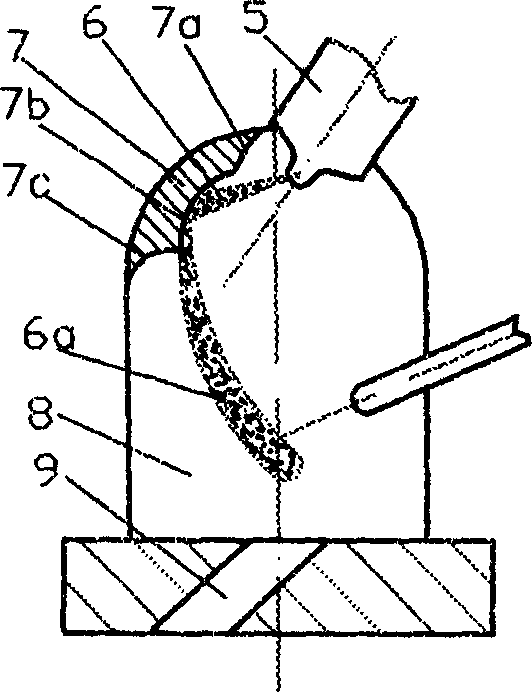

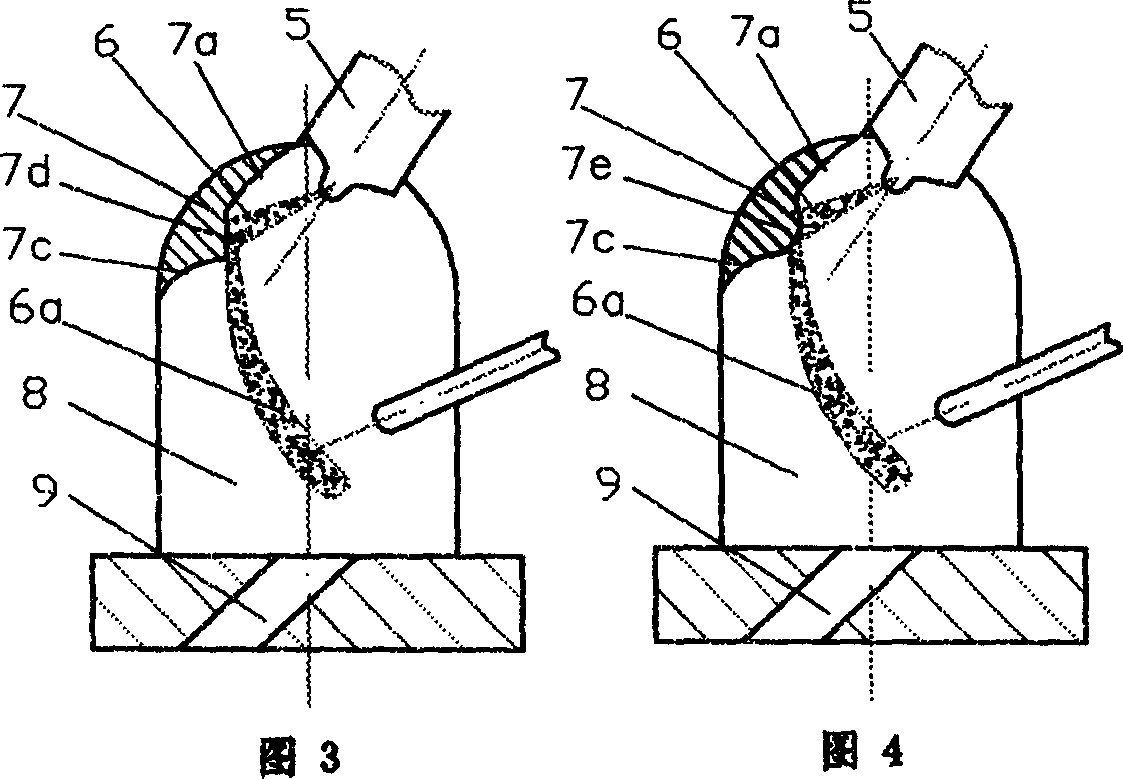

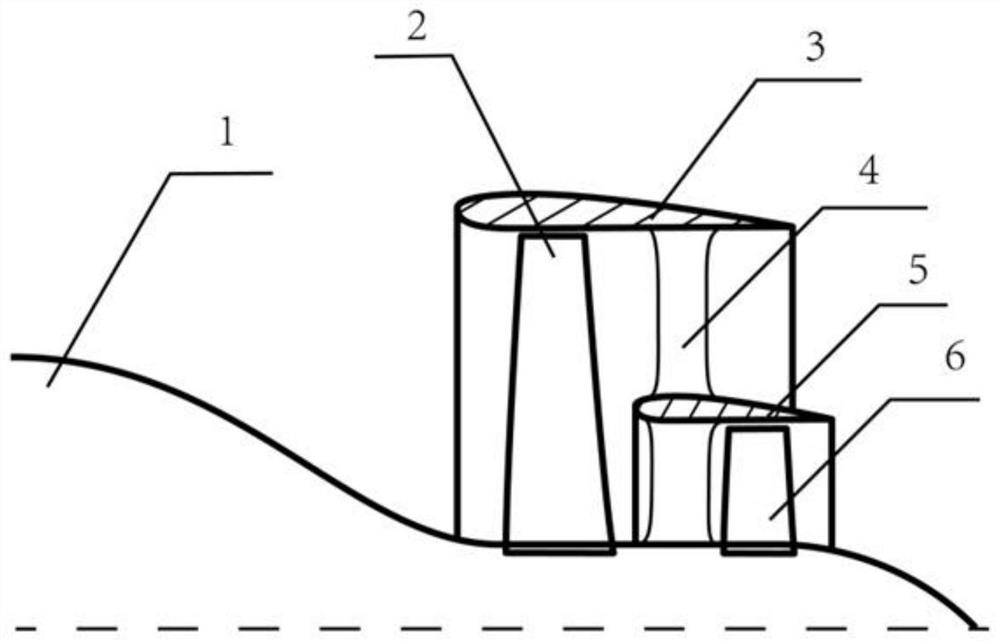

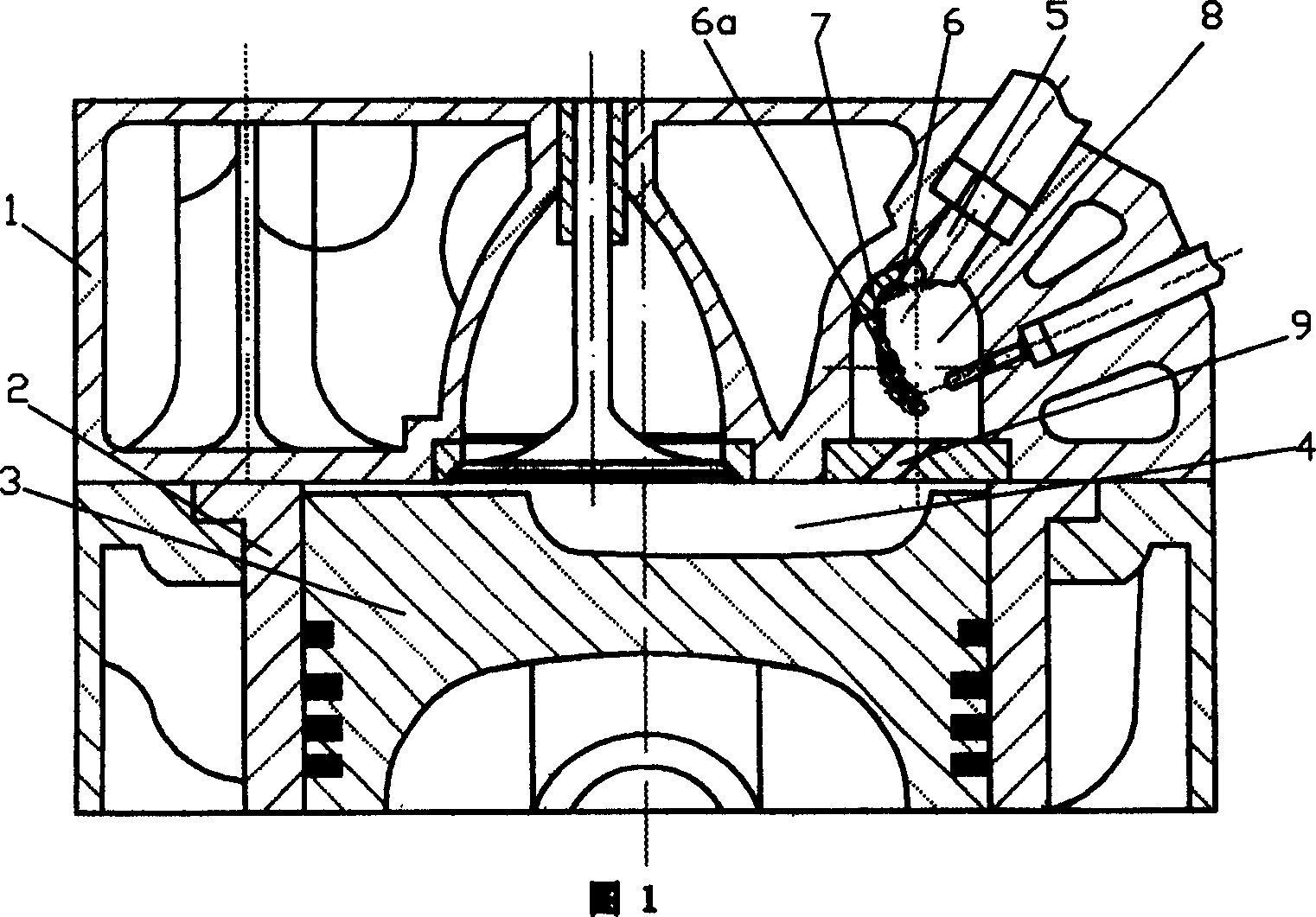

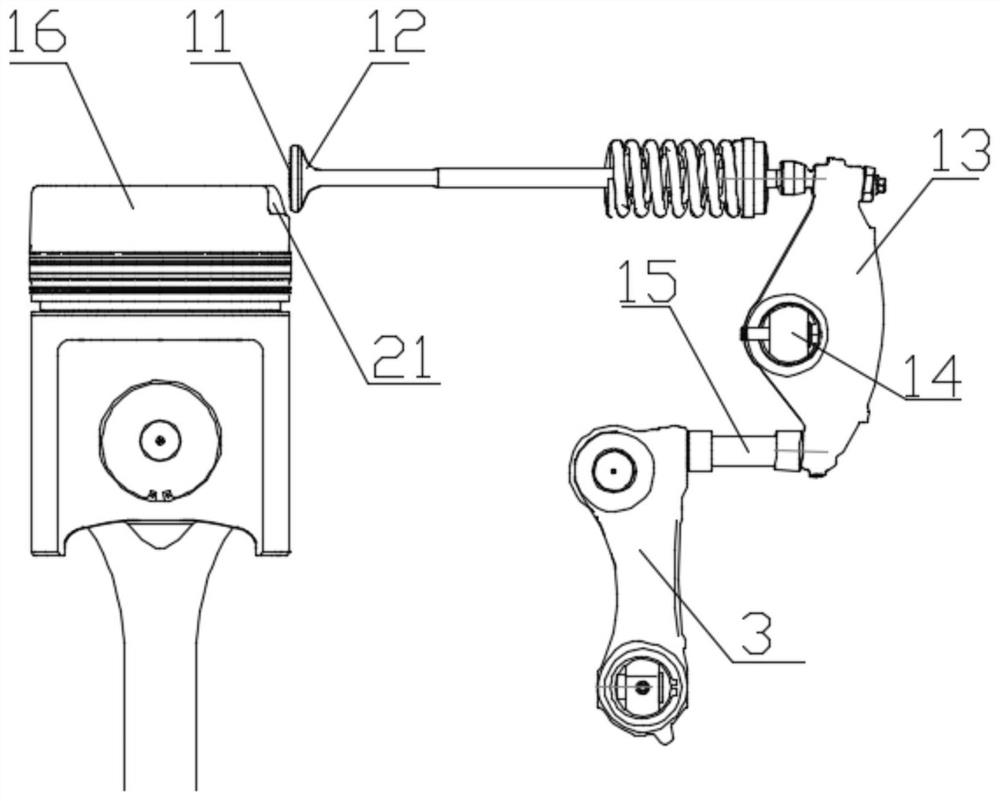

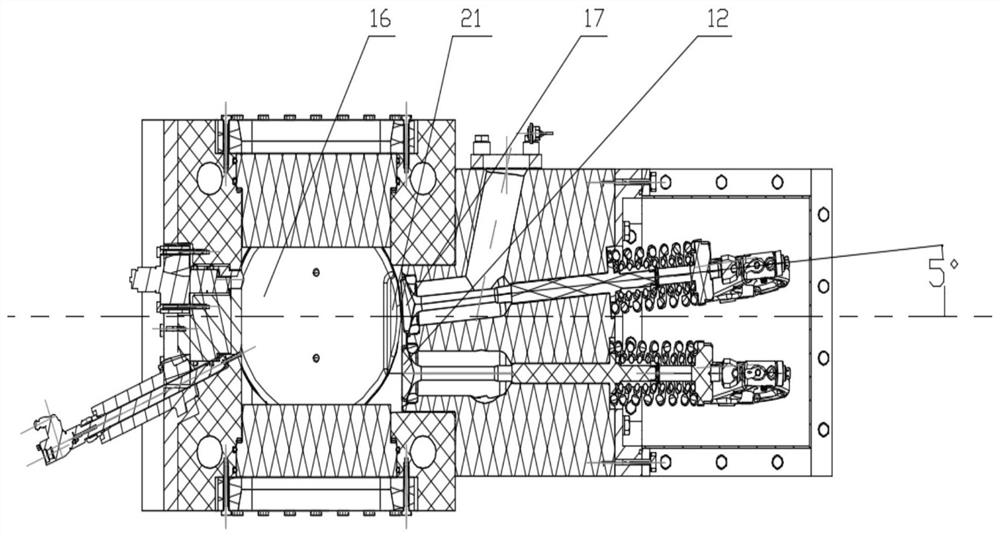

Combined type combustion chamber for two-stroke aviation heavy oil plunger engine

InactiveCN107060986ACompact structureReduce weightInternal combustion piston enginesCylinder headsAviationCross-ratio

The invention discloses a combined type combustion chamber for a two-stroke high-power cross-ratio aviation heavy oil plunger engine. The combined type combustion chamber comprises a cylinder body, a cylinder sleeve, a cylinder head, a plunger and a mono-block pump; the cylinder head is fixed to the top of the cylinder body, the cylinder sleeve is fixed in the cylinder body, and the plunger is arranged inside the cylinder sleeve; a concave pit A is designed in the middle of the top surface of the plunger, a concave pit B is designed in the middle of the bottom surface of the cylinder head, and the concave pit A and the concave pit B are all shallow pits; the concave pit A, the concave pit B and the cylinder sleeve are combined together to form the combined type combustion chamber; and the mono-block pump is fixed to the cylinder head, a nozzle of the mono-block pump extends into the combined type combustion chamber, and nozzle holes of the nozzle are located in the concave pit B. Two air inlets and one air outlet which are opposite to each other are designed and formed in the side wall of the lower portion of the cylinder body. According to the combined type combustion chamber, the structure is compact, the power to weight ratio is big, the combustion speed is high, and the maximum combustion pressure is small; the combustion temperature is low, and the air-exhausting quality is good; and the scavenging form is rotational flow scavenging, the charging loss is effectively lowered, and the volume efficiency is improved.

Owner:BEIHANG UNIV

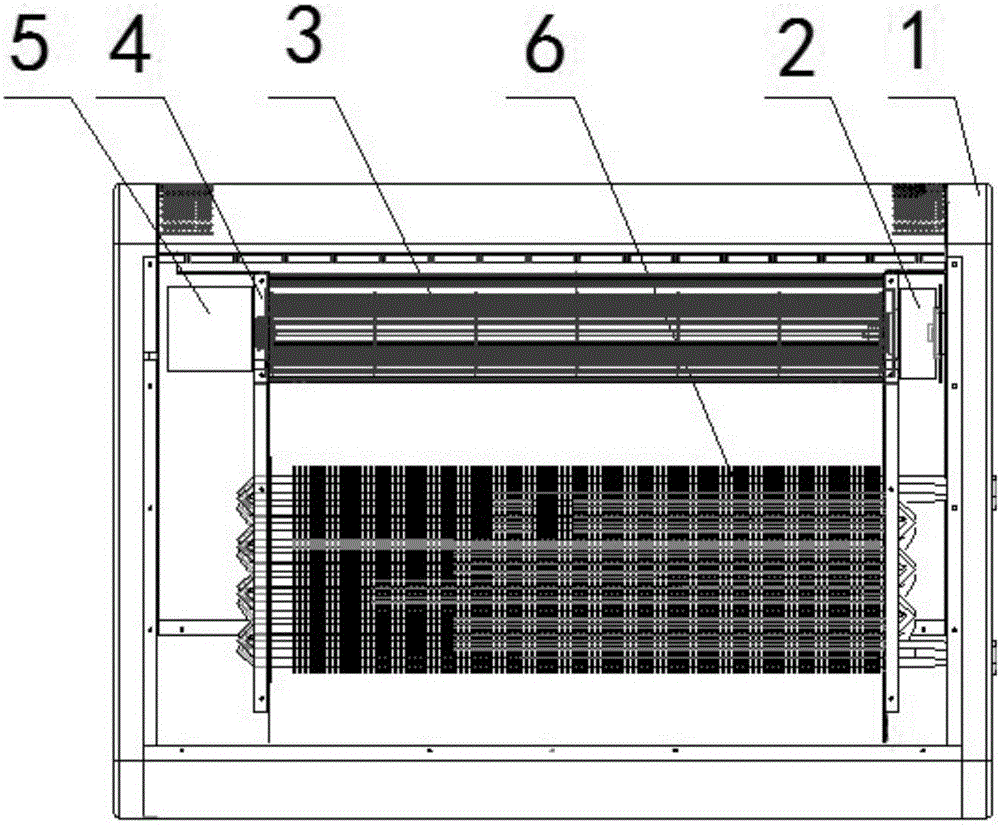

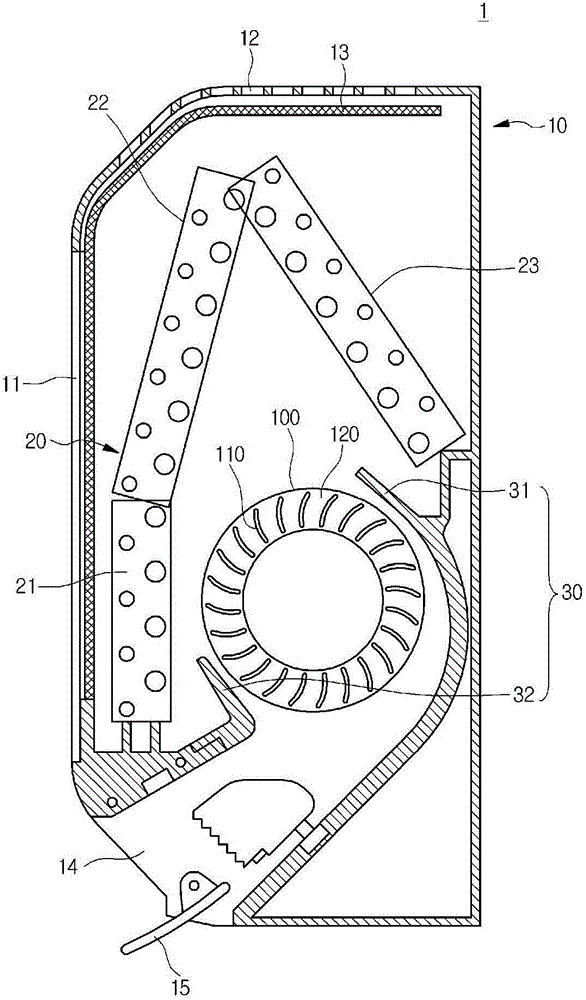

Novel variable frequency control radiator device

ActiveCN106091117AReduce vortex intensityReduce useless energy consumptionMechanical apparatusSpace heating and ventilation safety systemsImpellerMotor drive

The invention discloses a novel variable frequency control radiator device. The novel variable frequency control radiator device comprises an outer shell and a surface cooler, wherein a direct current variable frequency motor is arranged inside the outer shell; the direct current variable frequency motor drives a cross-flow impeller to rotate; the direct current variable frequency motor and the cross-flow impeller are mounted inside a combined guide mechanism inside the outer shell; a variable frequency controller is arranged at one end of the cross-flow impeller; the cross-flow impeller comprises a plurality of blades and a fixing disc used for fixing the blades; the blades are S-shaped structures; one parts of the blades extend out of the edge of the fixing disc; and the other parts of the blades are fixed in arc-shaped holes in the edge of the fixing disc. According to the variable frequency control radiator device, the fan coil radiator at the tail end can be controlled through frequency conversion, the system operation is automatically adjusted according to practical load, the useless energy consumption is reduced, the high energy consumption problem of a household central air conditioner is solved, the air blasting effect is better, the noise is low, and the vortex intensity inside the cross-flow impeller can be reduced.

Owner:山东中科能人工环境有限公司

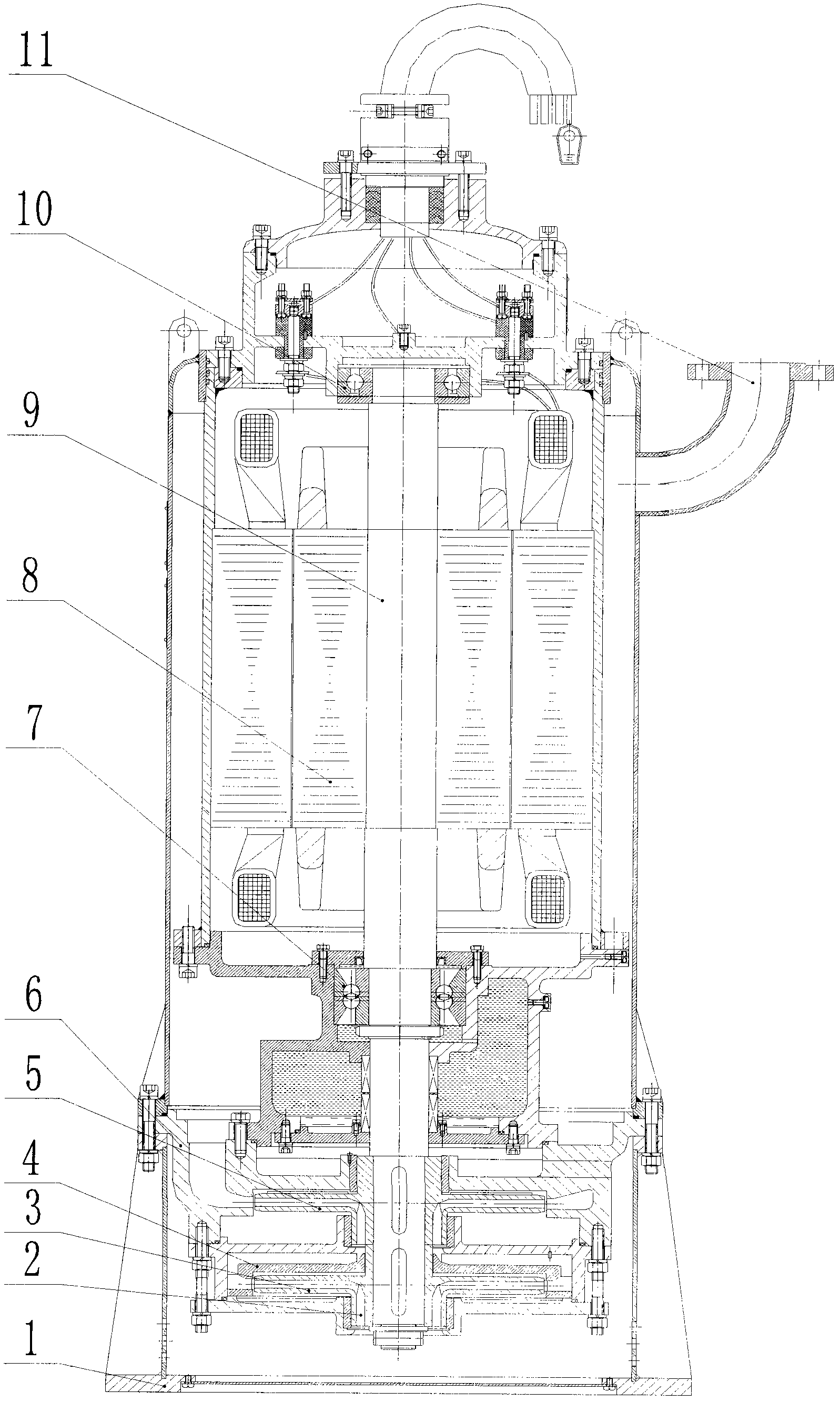

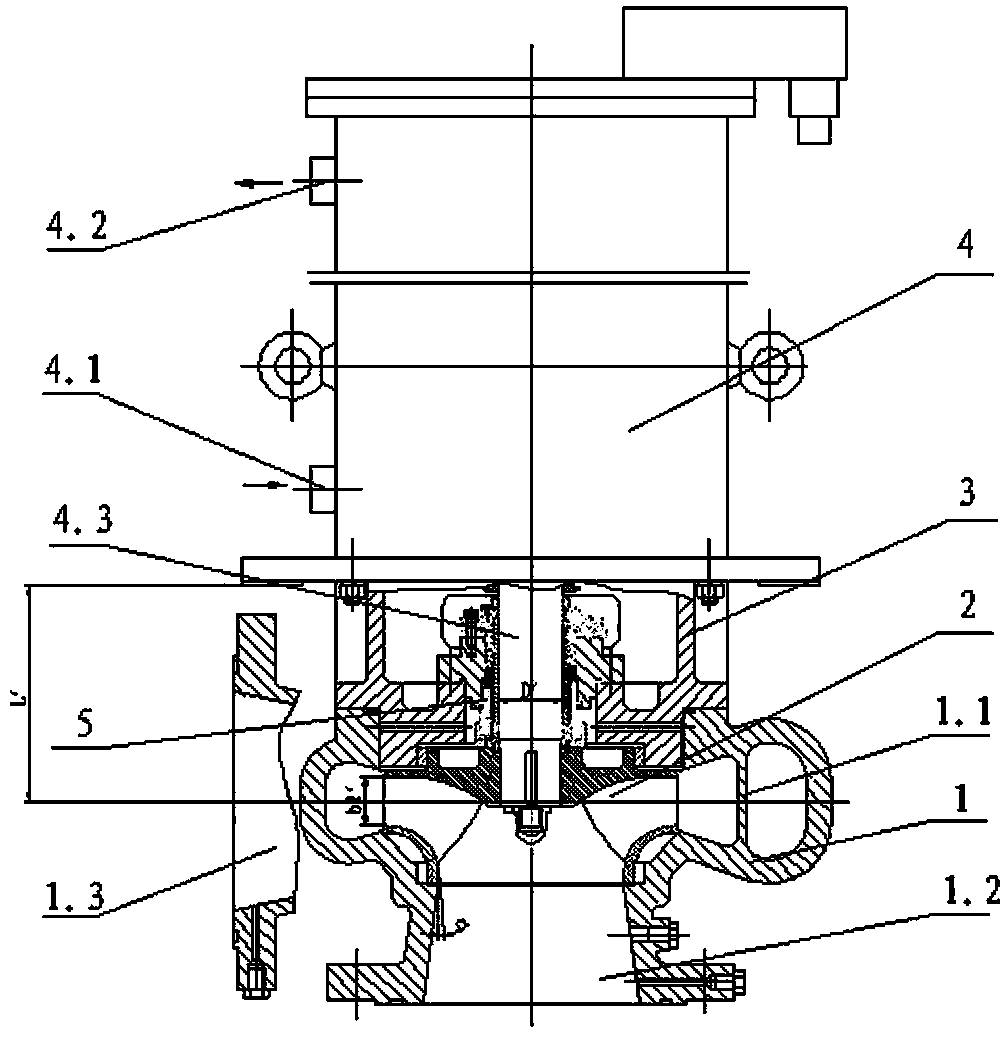

Vertical centrifugal pump unit with noise reduction function and low vibration level

InactiveCN104295506AImprove rigidityReduce vibration sourcesPump componentsPump installationsEngineeringNoise reduction

The invention discloses a vertical centrifugal pump unit with a noise reduction function and a low vibration level. The vertical centrifugal pump unit comprises a pump, an impeller, a bracket, a motor and a shaft seal. The pump is of a vertical structure, the impeller is arranged in a flow channel of an inner cavity of the pump, an upward opening of the pump body is connected to the lower side of the bottom surface of the bracket, the motor is connected to the upper end surface of the bracket in a positioned manner, and a downward extending shaft of the motor penetrates the bracket and then is connected with the shaft seal and the impeller in a positioned manner. A water inlet is formed in a side surface of an output shaft seat of the motor, a water outlet is formed in a side surface of the shaft seat and is positioned at the other end of the motor, and the water inlet and the water outlet are communicated with each other in the motor to form an inner water cooling structure. The vertical centrifugal pump unit has the advantages that the vertical centrifugal pump unit is designed for meeting running matching requirements of manned deep diving devices at special working conditions, the pump, the impeller, the bracket and the motor are structurally optimally designed on the premise that the hydraulic performance of the pump unit is guaranteed, mechanical and hydraulic vibration sources of the pump unit can be weakened, and accordingly the purpose of reducing vibration and noise can be achieved.

Owner:江苏振华海科装备科技股份有限公司

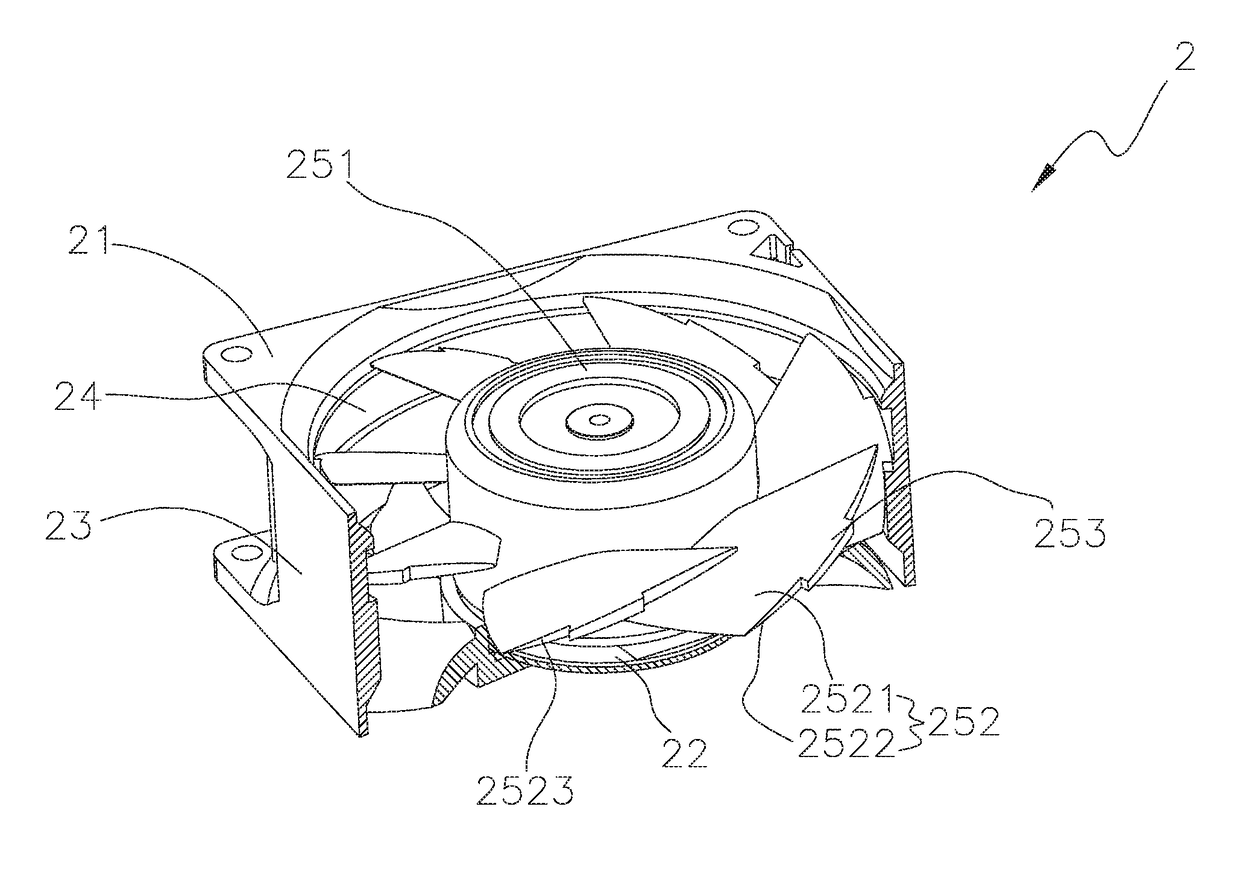

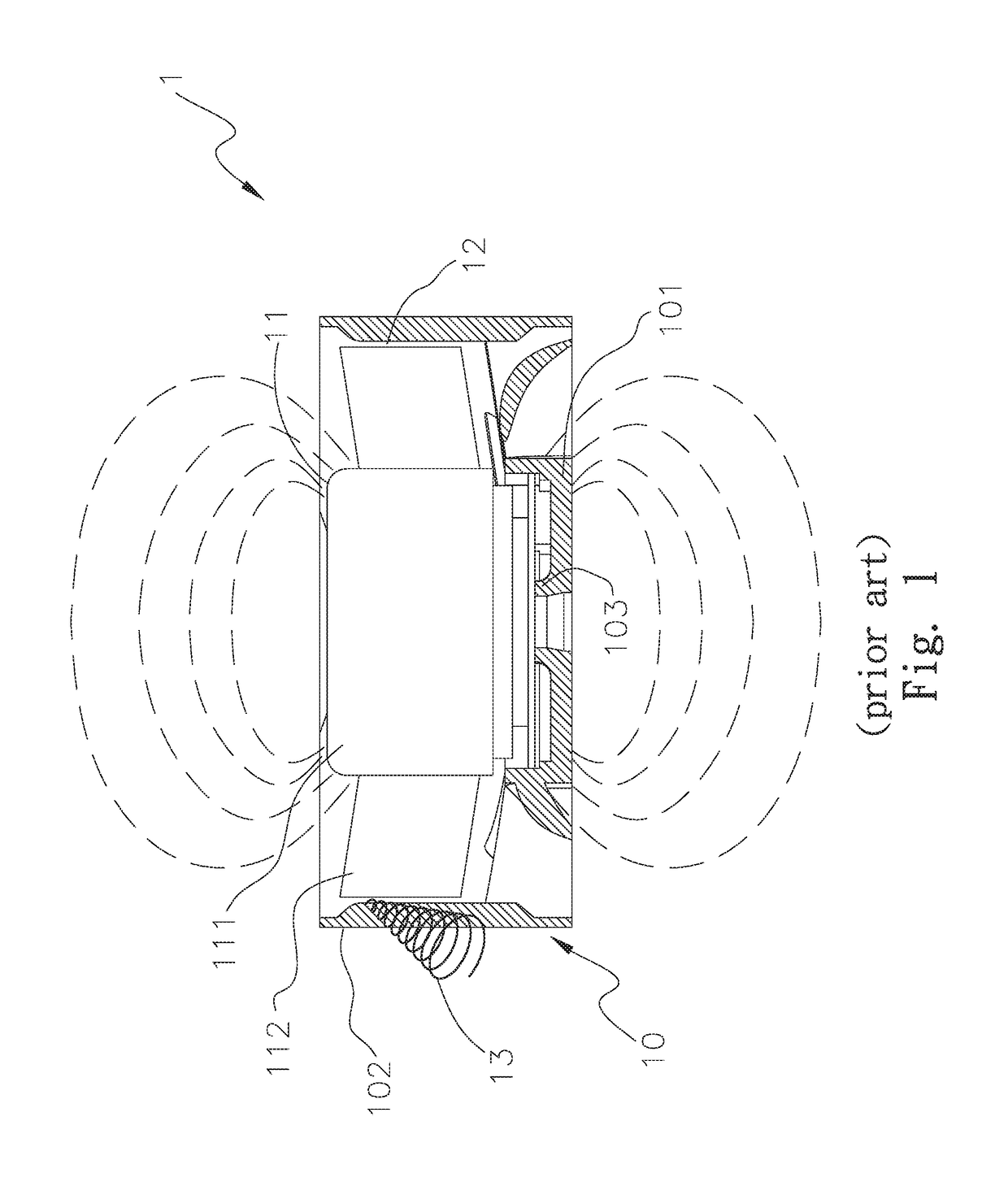

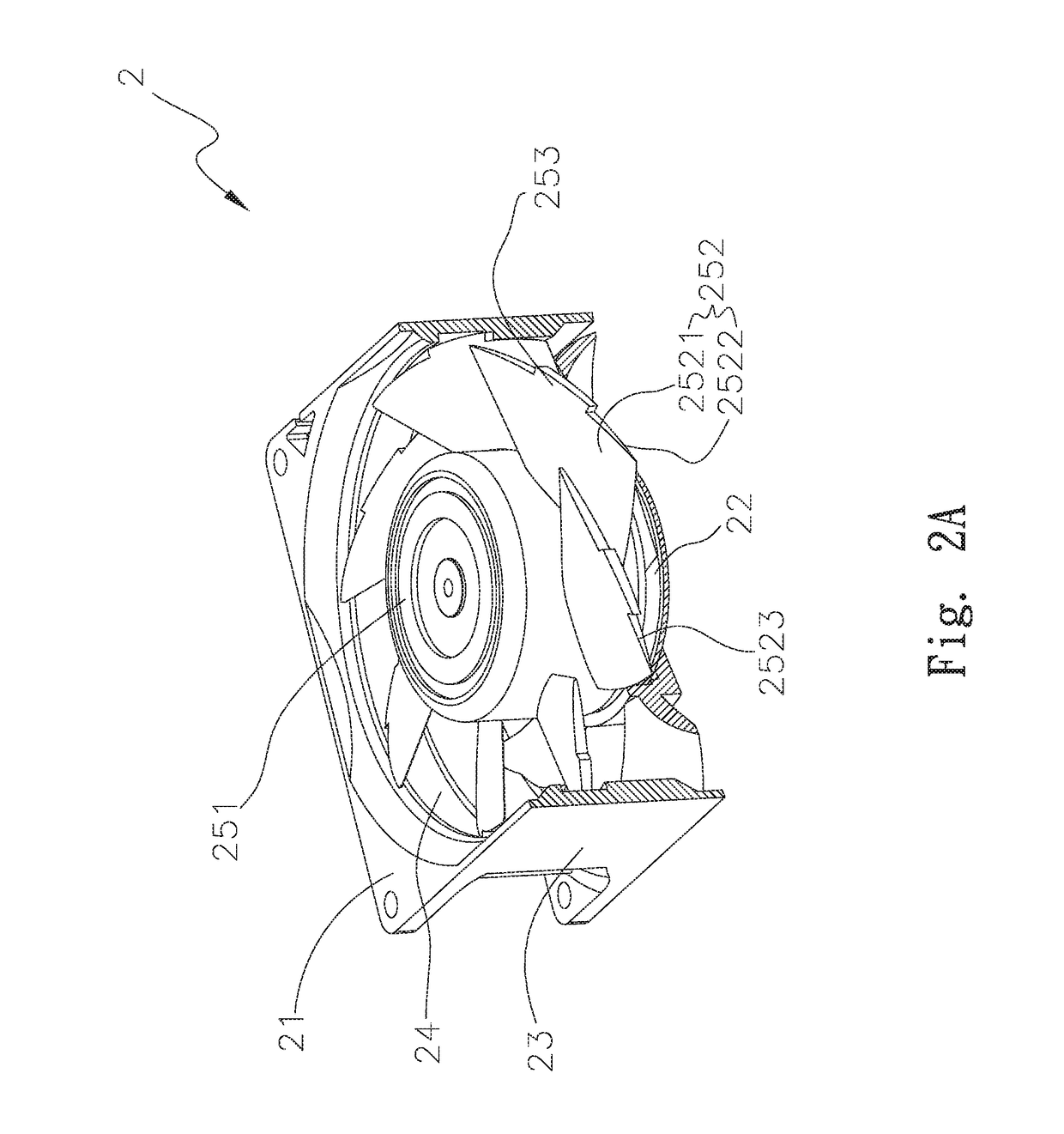

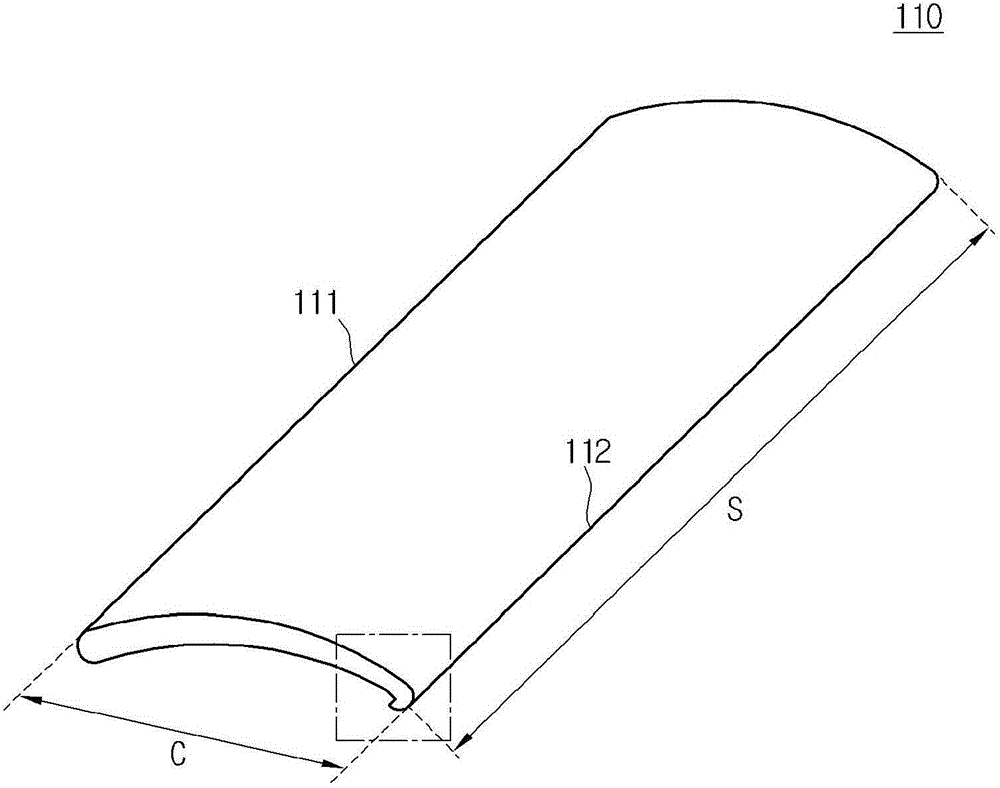

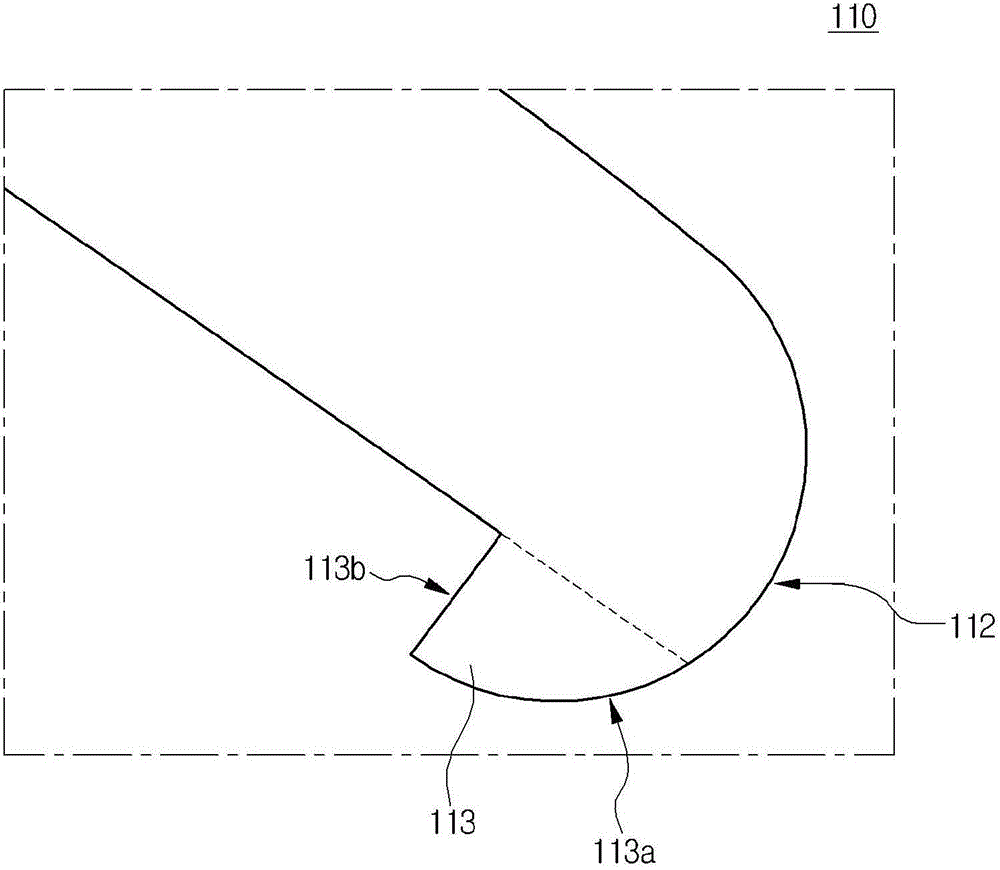

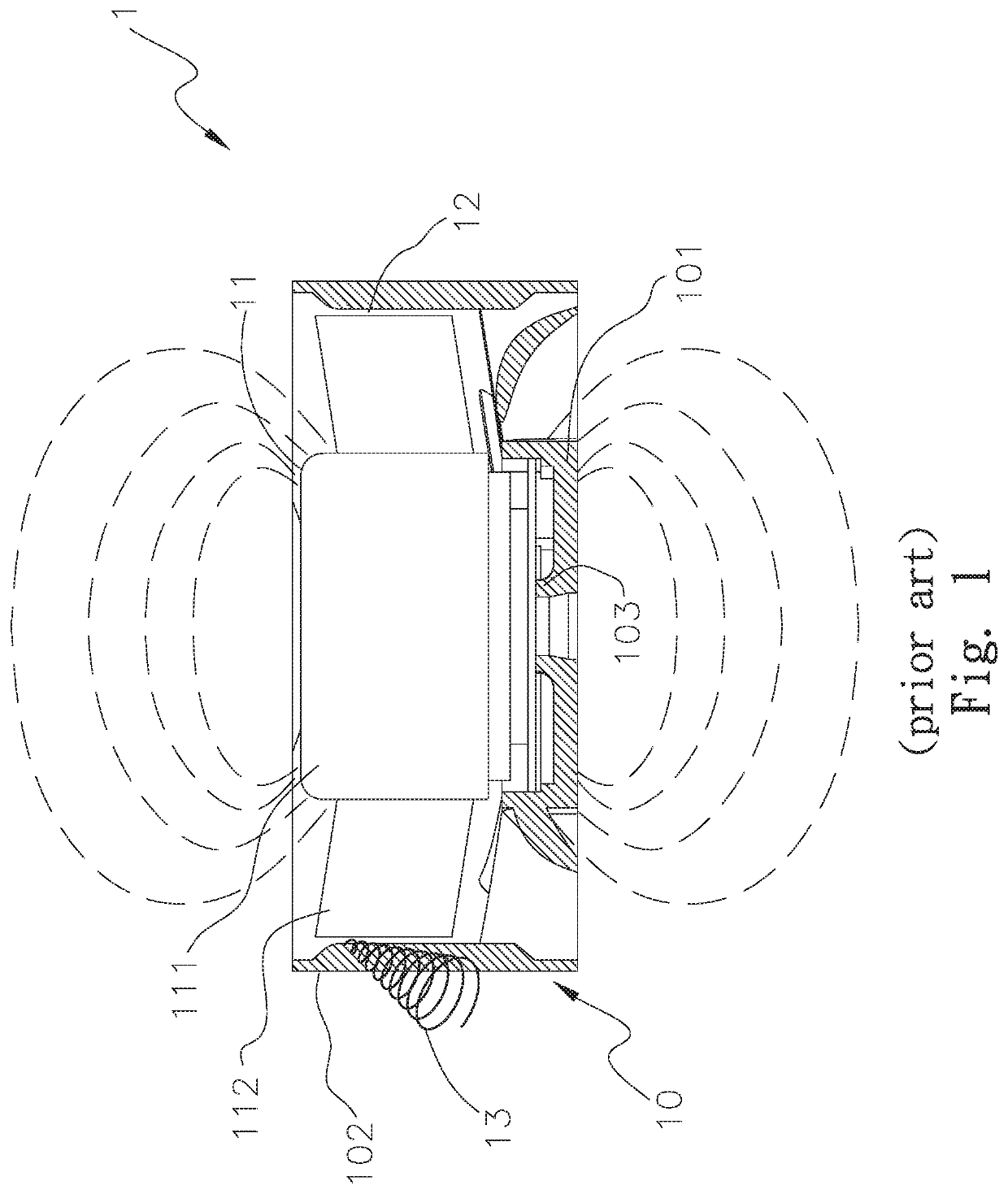

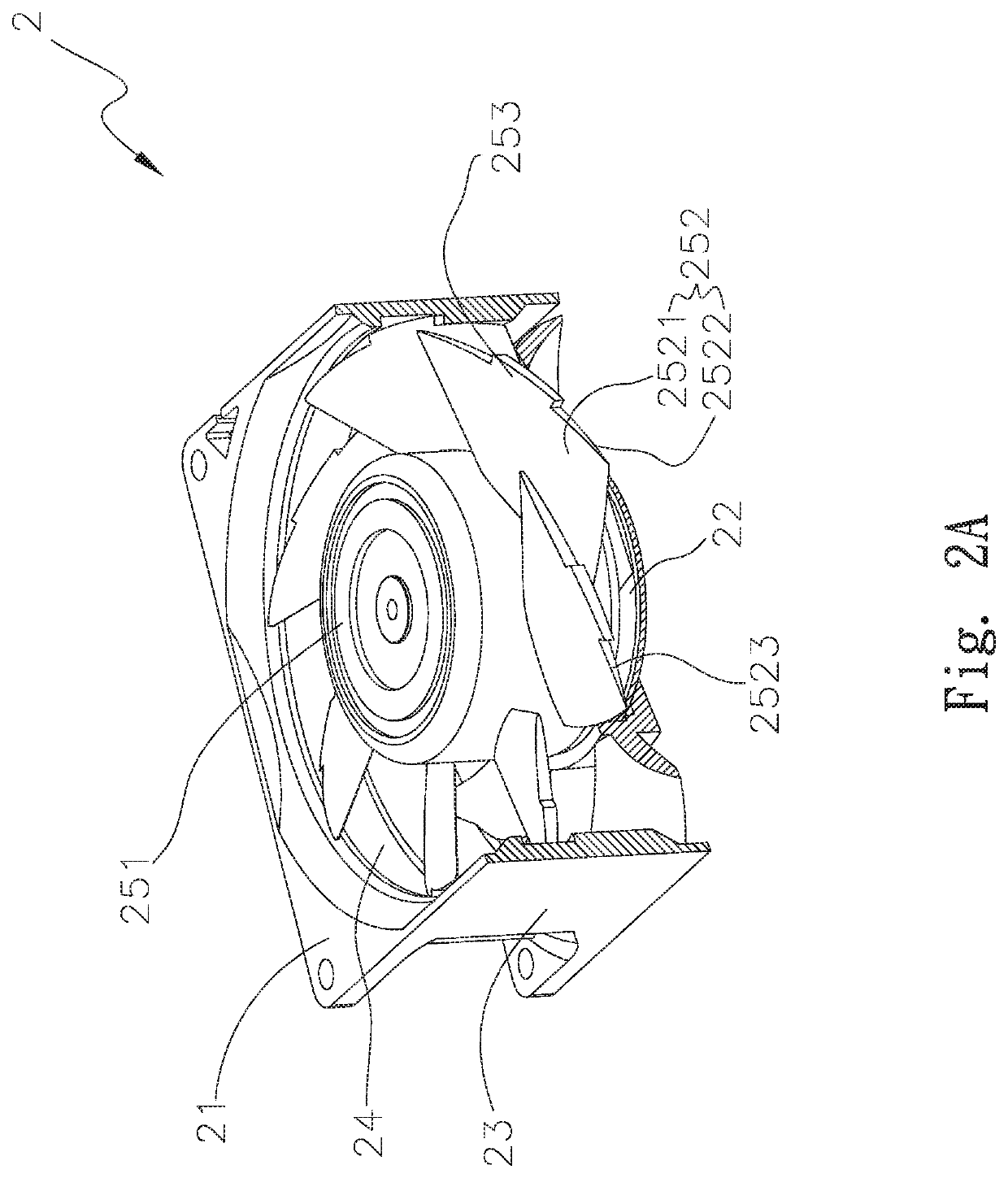

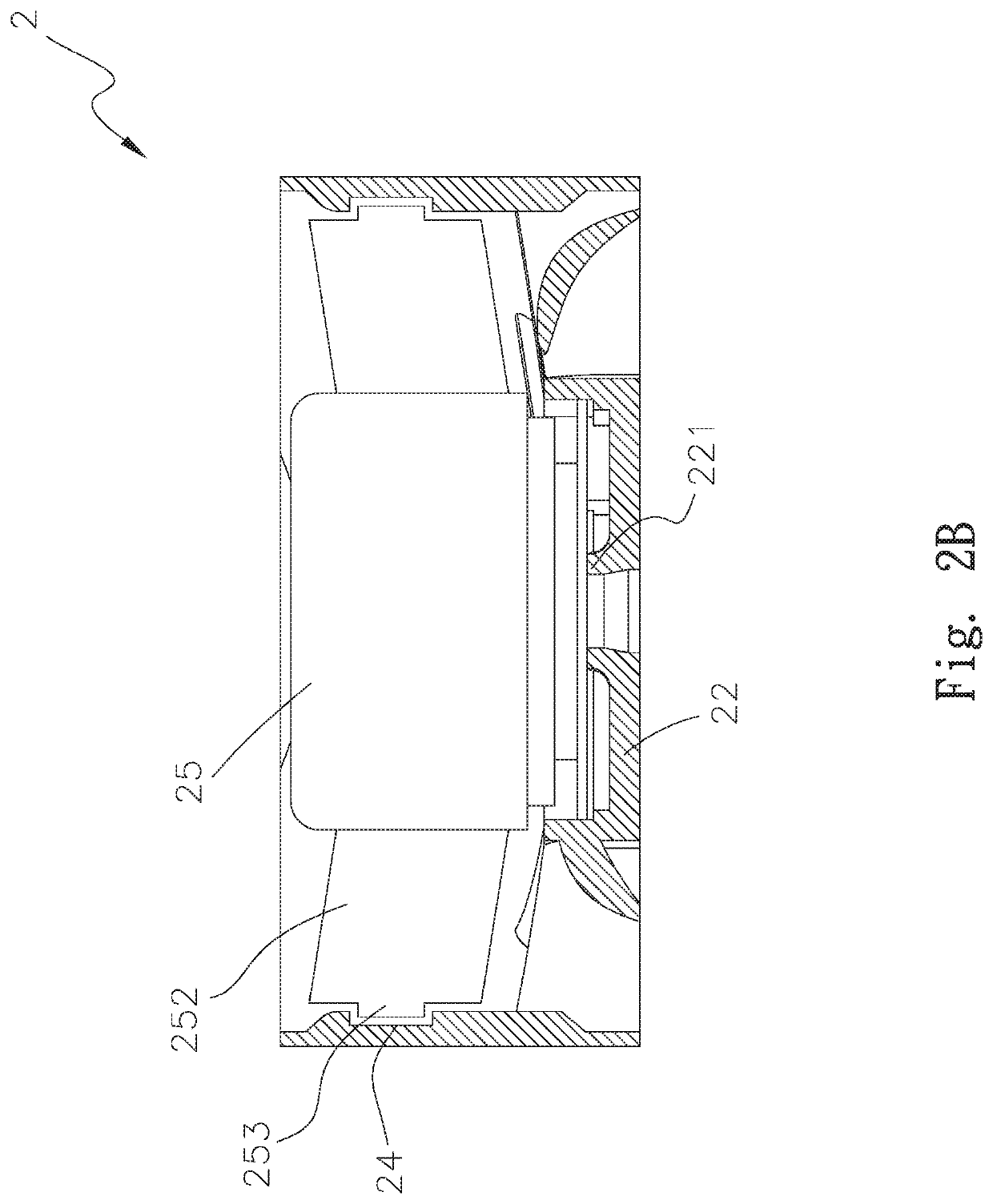

Fan structure

ActiveUS20180306207A1Strength of be greatly minifyWeak in strengthPump componentsEngine fuctionsImpellerEngineering

A fan structure includes a frame body and a fan impeller. The frame body has a base seat and an annular wall. A bearing cup upward extends from a center of the base seat. At least one groove is annularly formed on inner wall face of the annular wall. The fan impeller is pivotally disposed in the bearing cup and has a hub and multiple blades outward extending from the hub. Each blade has an end edge. At least one protrusion section outward protrudes from the end edge into the groove. According to the design of the fan structure, the protrusion section can destroy the production of the vortex of the blade of the conventional fan so as to greatly minify the strength of the vortex. Therefore, the structure of the sound field of the vortex is changed so that the noise of the fan structure is lowered.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

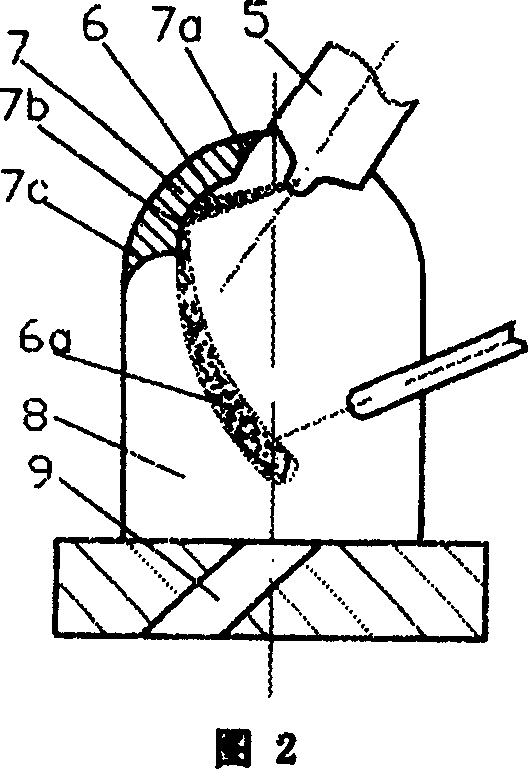

Collision spray vortex chamber of internal combustion engine

InactiveCN1558106AReduce vortex intensityEmission reductionInternal combustion piston enginesFuel re-atomisation/homogenisationCombustorExternal combustion engine

The present invention is collision atomizing eddy current chamber for internal combustion engine and belongs to the field of mixed gas formation and combustion in internal combustion engine. The colliding stage set inside the eddy current chamber makes the primary oil beam jetted from the oil nozzle form fast even fine secondary oil beam, and the comprehensive effects of the secondary oil beam and air eddy current inside the eddy current chamber form excellent inflammable gas mixture resulting in fast and perfect combustion. The area of the connecting channel between the main combustor and the eddy current chamber is increased to lower the eddy current strength inside the eddy current chamber. The present invention results in raised economic performance, improved cold starting performance and load adaptability and obvious reduced lower-load carbon smoke exhaust, while maintaining the available compression ratio.

Owner:DALIAN UNIV OF TECH

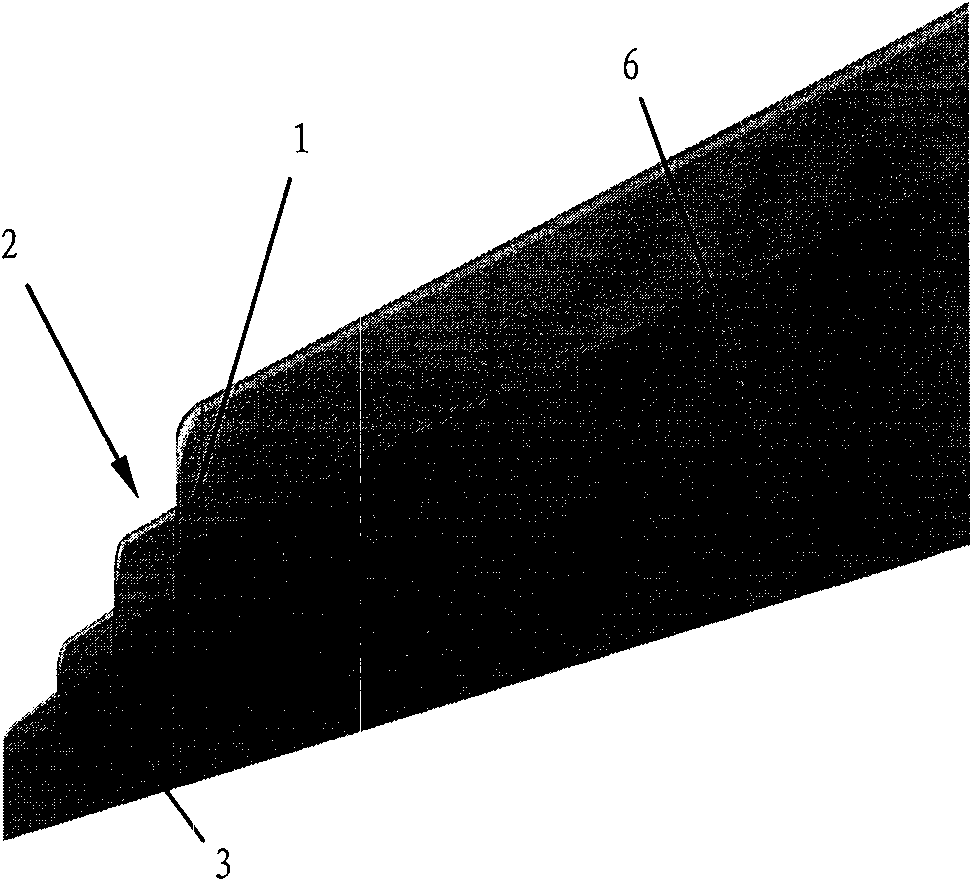

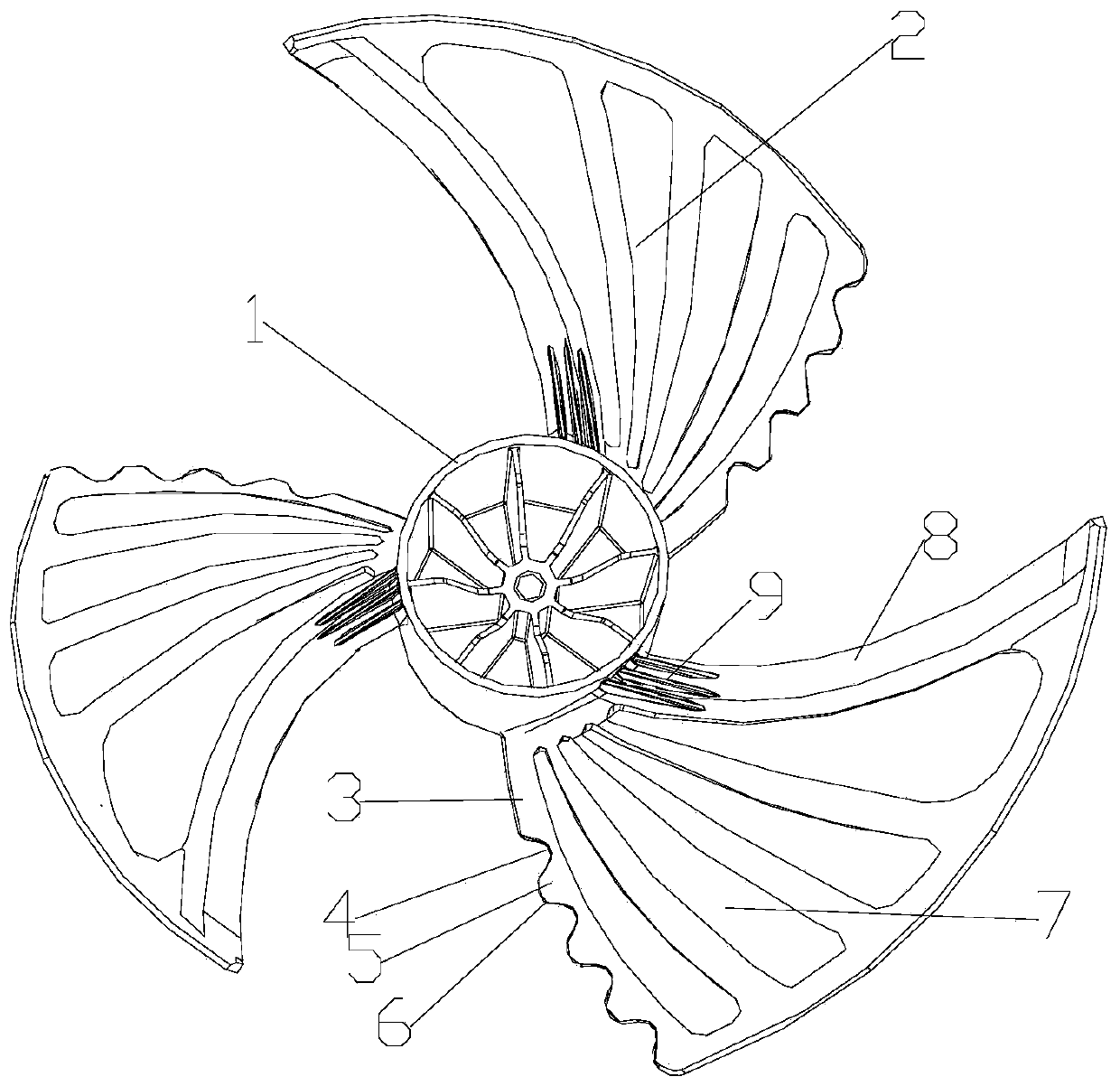

Axial flow fan blade and fan with the same

The invention relates to an axial flow fan blade and a fan with the same. The axial flow fan blade comprises a hub and a plurality of blades arranged around the hub, wherein a plurality of groove structures recessed in the direction perpendicular to a tail edge are arranged on a tail edge of each blade in the tail edge direction, a protrusion is formed between every two adjacent groove structures,the axial projection lines of edges of the protrusions are arcs, and the circle centers of the axial projection lines of the edges of the protrusions are located on the same circumferential line. A plurality of groove structures are formed on the tail edge of the blade, so the airflow on the pressure surface part dispersedly flows into a back pressure surface, the vortex generated by the back pressure surface is dispersed, the vortex intensity of the back pressure surface of the axial flow fan blade can be effectively weakened, and the impact of the wake vortex of the previous axial flow fanblade on the next axial flow fan blade is reduced, so the air volume can be effectively increased, and the noise of the axial flow fan is reduced.

Owner:NINGBO LANGDI IMPELLER MACHINERY

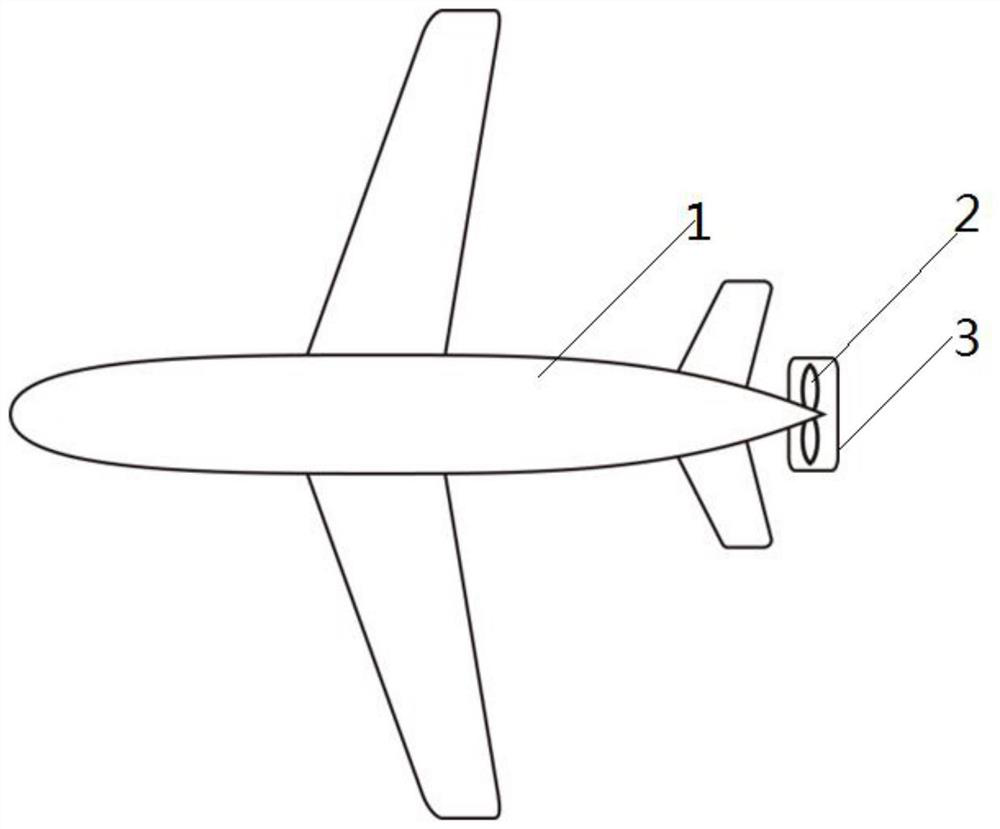

Boundary layer suction type propeller adopting large and small two-stage blades

ActiveCN113443124AIdeal circulation distributionSatisfy climb performancePropellersDrag reductionFlight vehicleClassical mechanics

The invention discloses a boundary layer suction type propeller adopting large and small two-stage blades. The boundary layer suction type propeller is mounted at the tail part of the aircraft; a large rotor and a small rotor are arranged on the thruster, blades of the large rotor adopt low rotating speed, thrust of a main part is generated, and the requirement for the climbing performance of the aircraft is met. the blades of the small rotor rotate at a higher speed, so that the load of the root can be increased, the load of the blades of the propeller is close to an ideal load, and energy contained in downstream airflow of the propeller is weakened to the maximum extent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

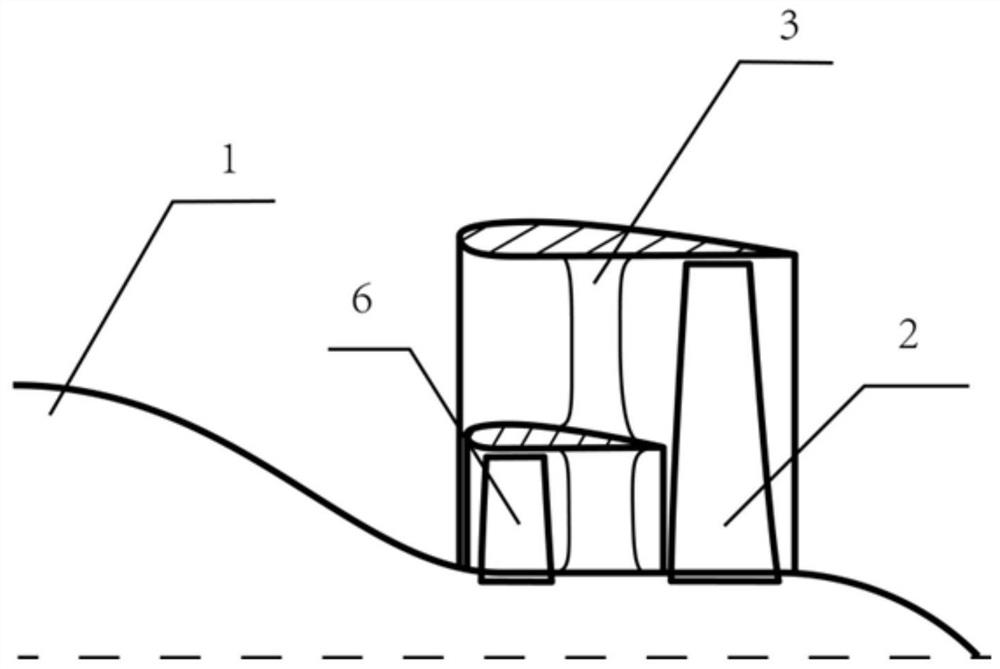

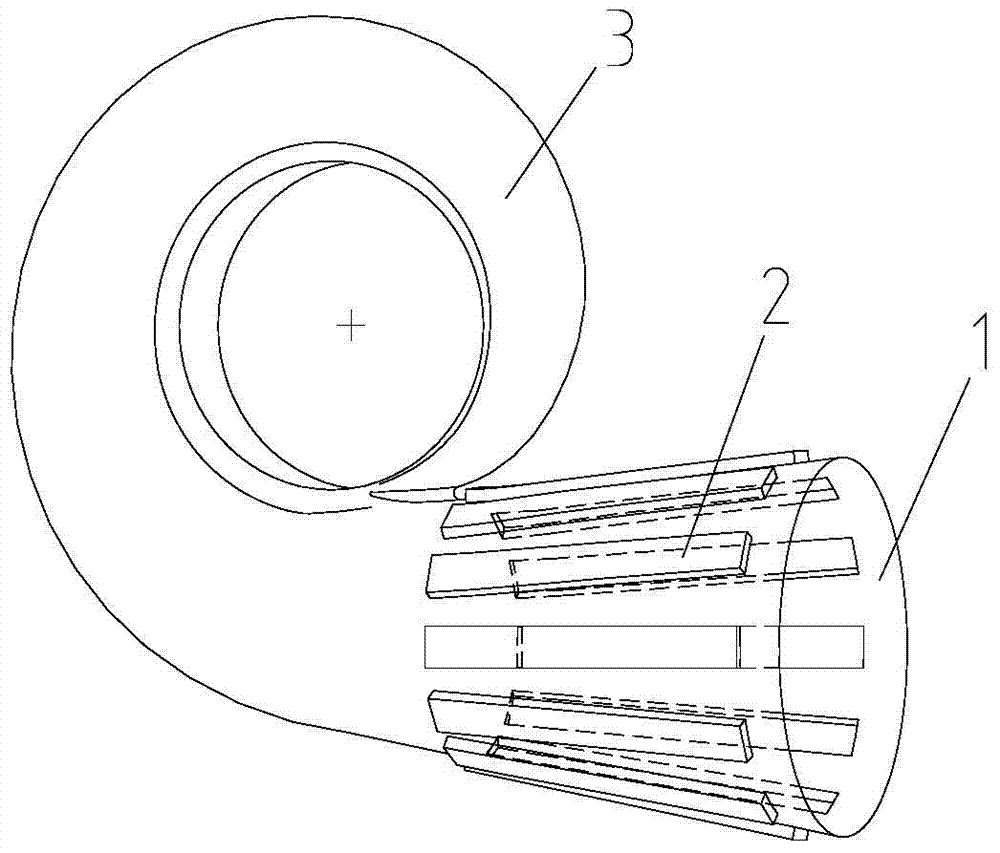

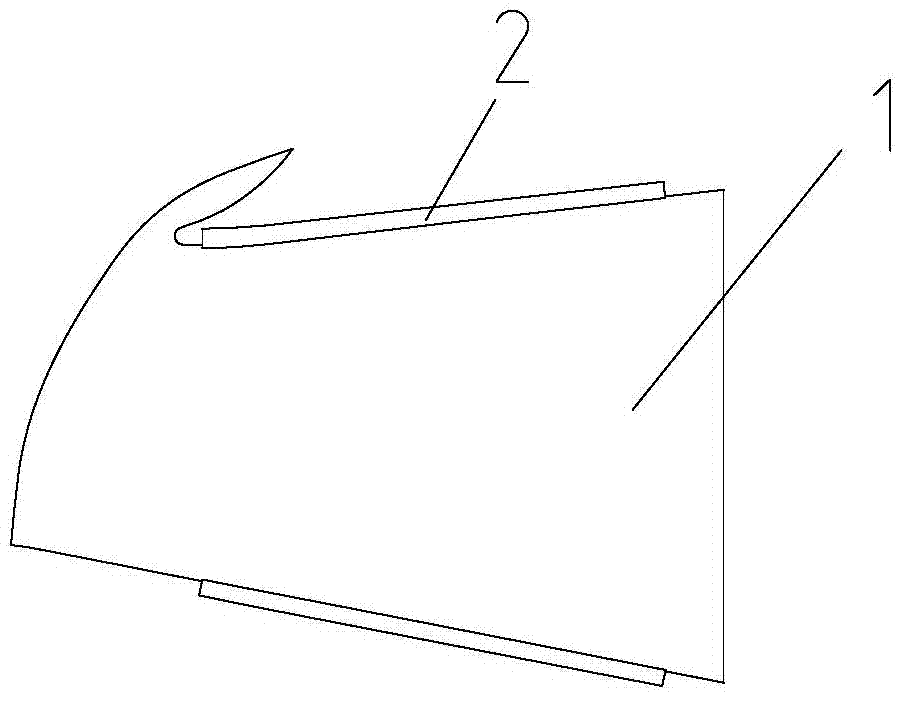

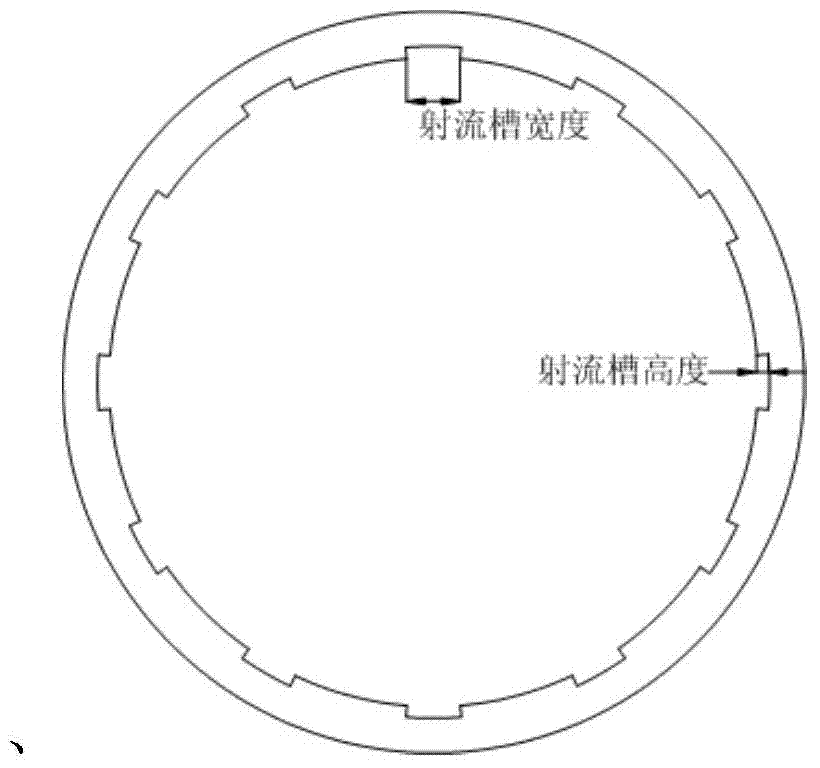

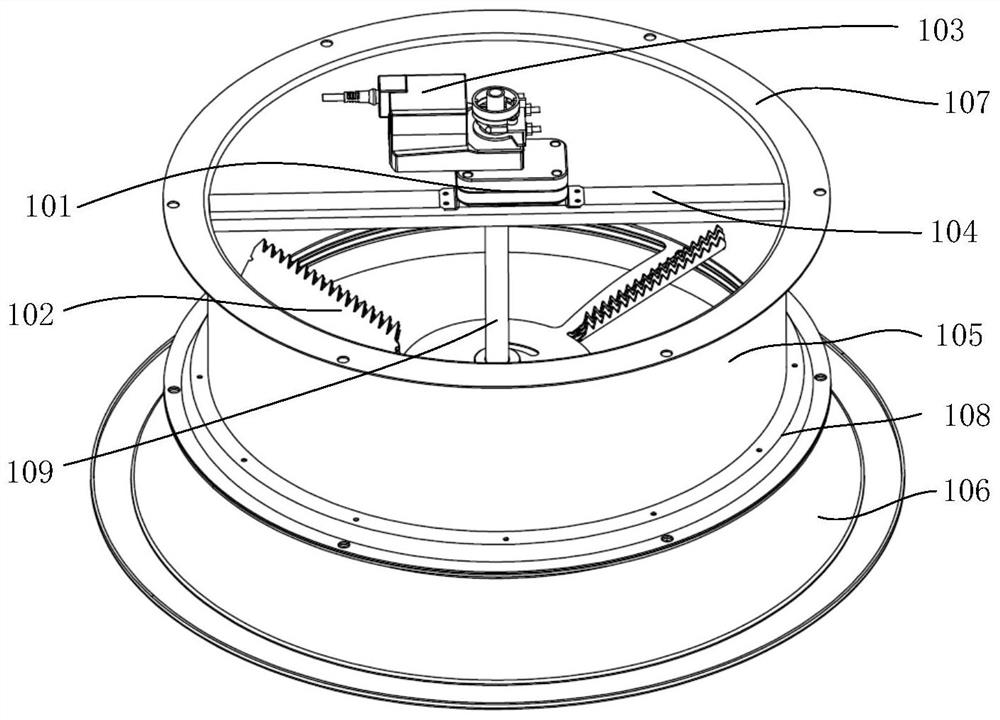

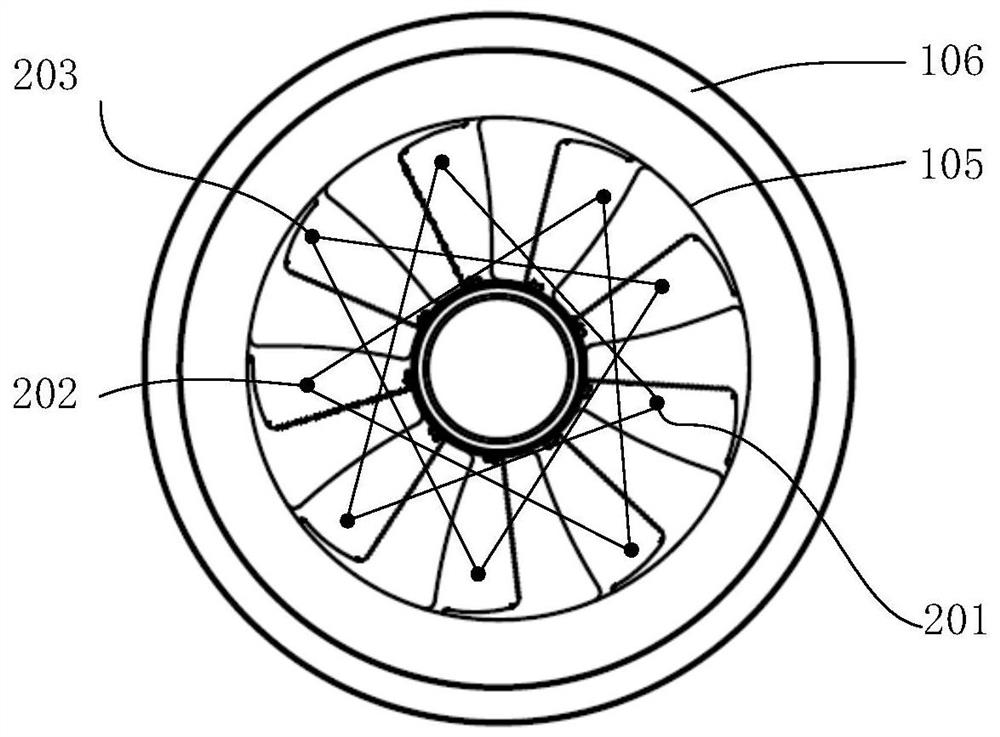

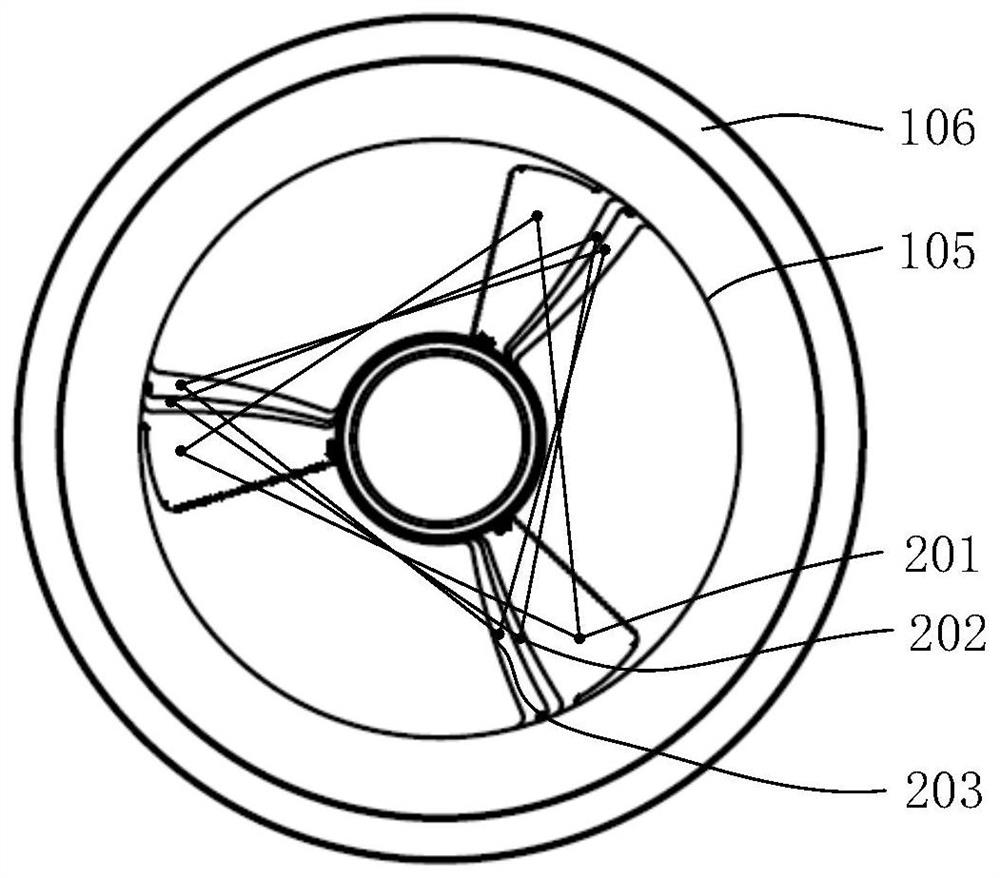

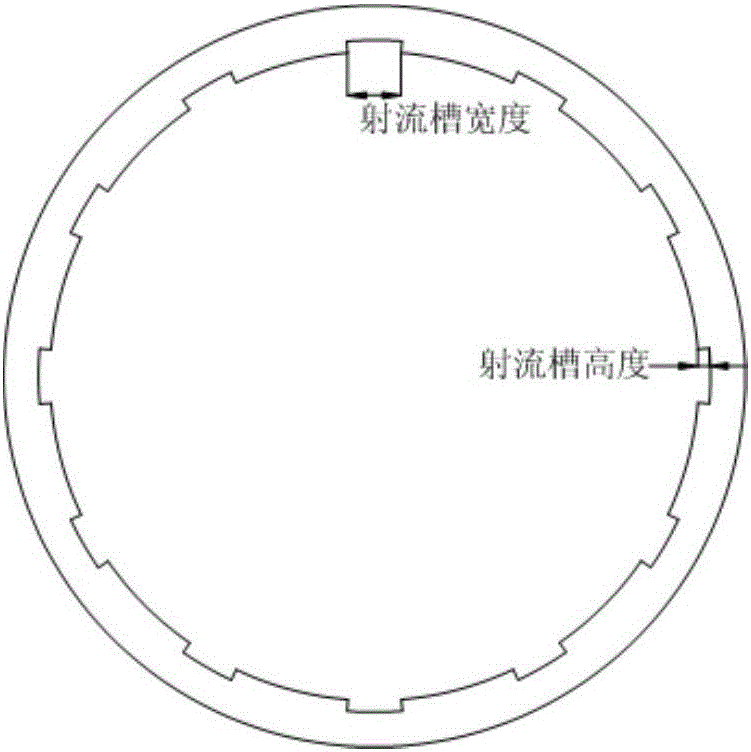

Eddy current confinement centrifugal pump pumping chamber and centrifugal pump with same

ActiveCN104329293AImprove running stabilityEasy to processPump componentsPumpsPump chamberEddy current

The invention discloses an eddy current confinement centrifugal pump pumping chamber and a centrifugal pump with the same. In the eddy current confinement centrifugal pump pumping chamber, jet grooves are uniformly formed in the inner wall of a diffusing section of the pumping chamber along the circumference; the length direction of the jet grooves is parallel to the flow line of the diffusing section of the pumping chamber. The jet groove structure produces a micro jet by using adverse pressure gradient in the diffusing section of the pumping chamber, and the micro jet is mixed with a main flow in the diffusing section of the pumping chamber to reduce the eddy current intensity in the diffusing section and confine eddy current development in the diffusing section, so that the stability for operation of the centrifugal pump is improved; meanwhile the micro jet has extremely small influence on the main flow in the diffusing section of the pumping chamber and also has extremely influence on the operation efficiency of the centrifugal pump. The eddy current confinement centrifugal pump pumping chamber has a simple structure, is easy to machine and manufacture and is applicable to any type of centrifugal pump.

Owner:TSINGHUA UNIV

Cross-flow fans and air conditioners

ActiveCN103133360BReduce generationIncrease flow ratePump componentsRadial flow pumpsUltimate tensile strengthAerospace engineering

Owner:LG ELECTRONICS INC

Ladle nozzle slag entrapment prevention dam control method

InactiveCN113042725AReduce vortex intensityImprove cleanlinessMelt-holding vesselsCasting cleaning apparatusSlagDross

The invention discloses a ladle nozzle slag entrapment prevention dam control method, and relates to the technical field of molten steel smelting. According to the ladle nozzle slag entrapment prevention dam control method, a linear slag entrapment prevention dam is poured between the north side of a ladle bottom nozzle and the ladle wall, the pouring material and the ladle bottom working layer material are corundum spinel pouring materials, the height is 400mm, under the action of the nozzle slag entrapment prevention dam, the strength of eddy current formed in the ladle in the pouring process is weakened, and dross on the upper portion of molten steel is effectively prevented from being involved into a continuous casting tundish along with the eddy current. According to the ladle nozzle slag entrapment prevention dam control method, the ladle nozzle slag entrapment prevention dam is arranged, the large ladle slag discharging amount can be effectively reduced, under the action of the dam, the strength of the eddy current formed in the ladle in the pouring process can be weakened, the situation that steel slag is involved into the tundish along with the eddy current is effectively reduced, and the aims of improving the molten steel and casting blank cleanliness and effectively improving the plate blank quality are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

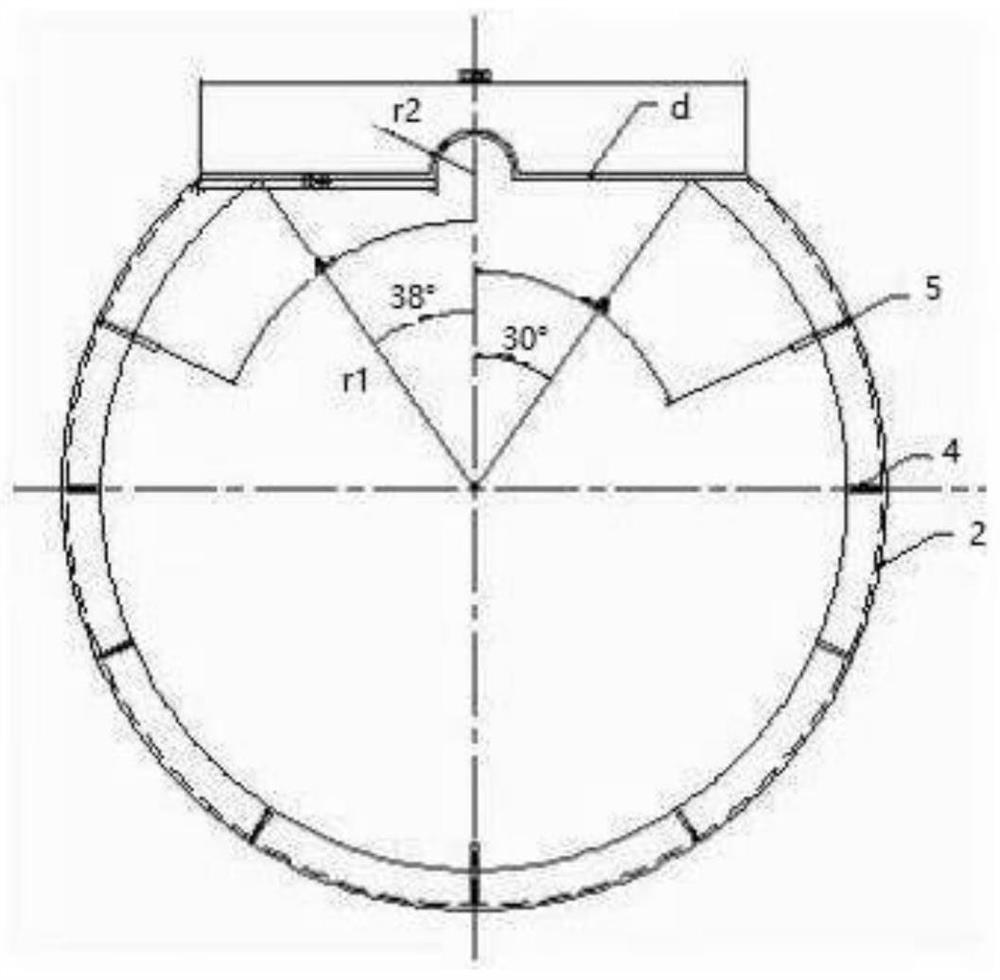

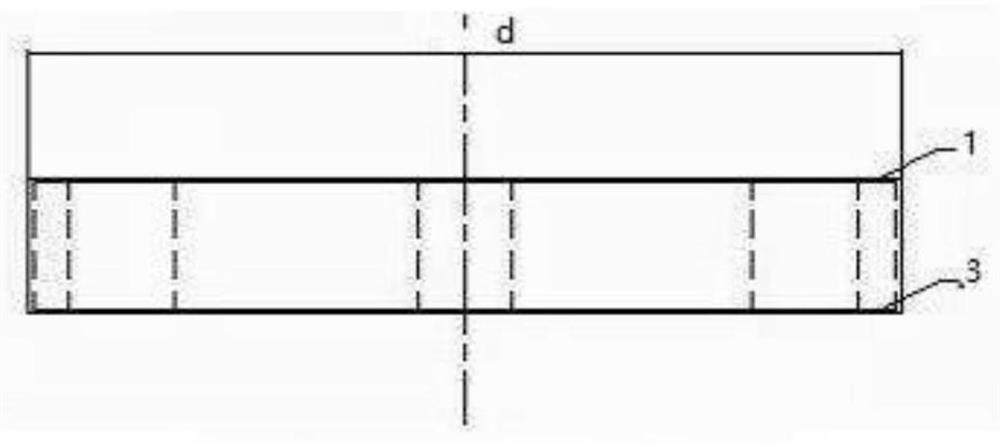

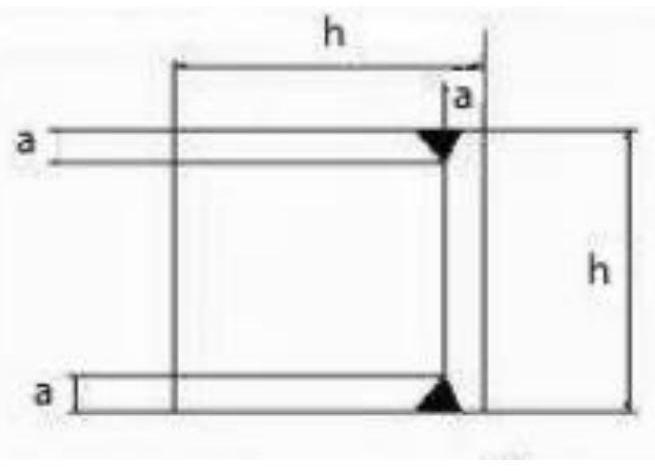

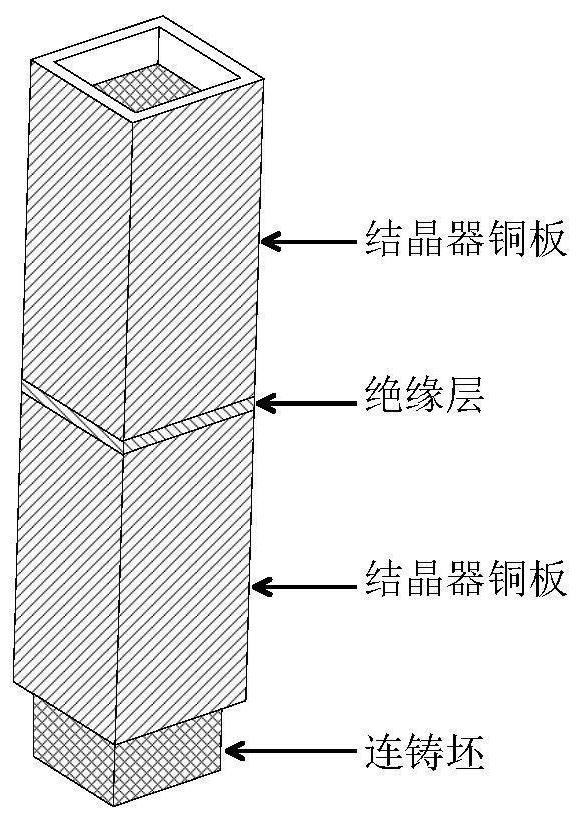

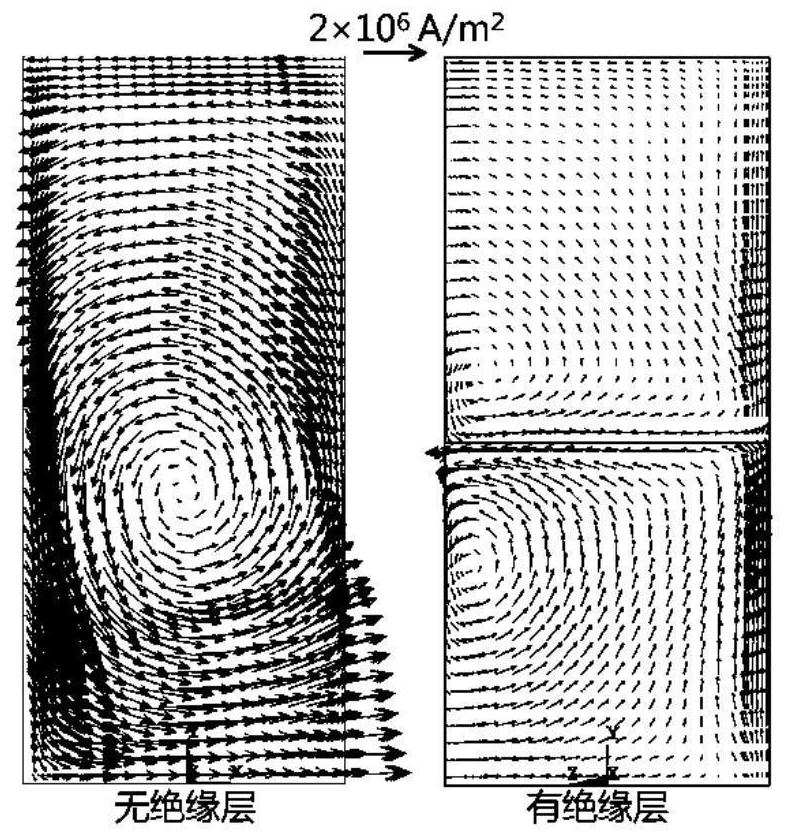

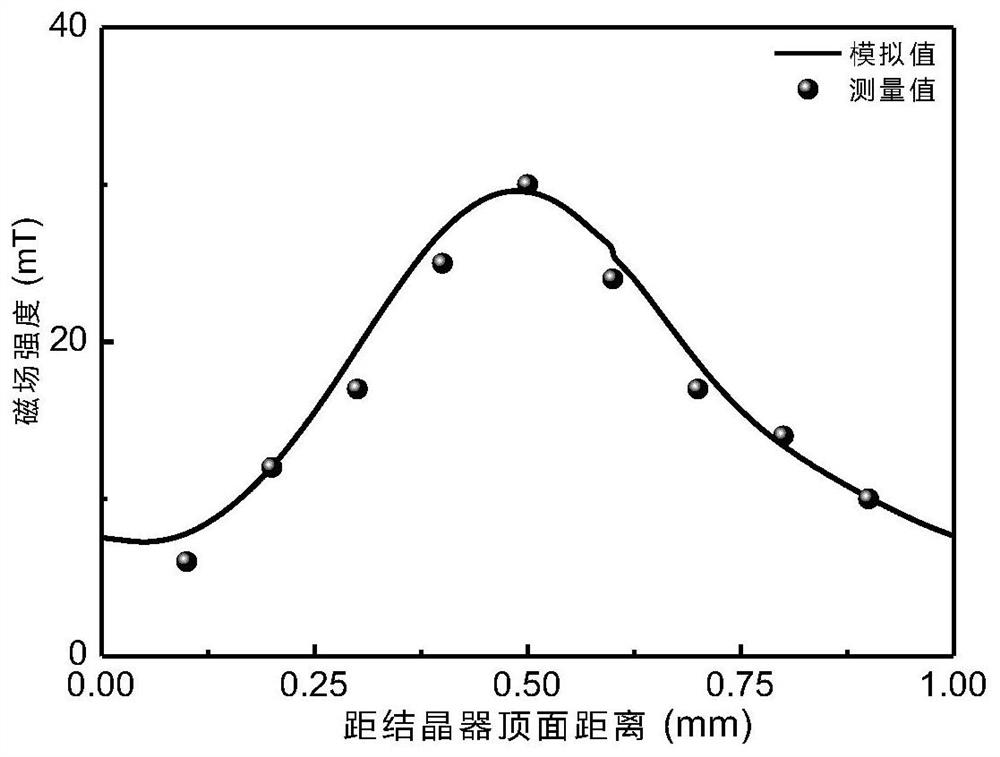

Continuous casting crystallizer copper plate design method for improving electromagnetic stirring efficiency

PendingCN113688470AReduce shielding effectImprove penetrationGeometric CADDesign optimisation/simulationElectromagnetic stirringElectromagnetics fields

The invention provides a continuous casting crystallizer copper plate design method for improving electromagnetic stirring efficiency, and belongs to the technical field of copper plate design. The method comprises the following steps: determining the thickness of an insulating layer through a continuous casting solidification heat transfer model, and determining the position of the insulating layer through an electromagnetic field model, thereby arranging the insulating layer in a traditional continuous casting crystallizer copper plate, so that the eddy intensity of the copper plate under the crystallizer electromagnetic stirring condition is reduced, and the shielding effect of the crystallizer on an alternating magnetic field is reduced. The penetrating power of the alternating magnetic field is improved, and the power consumption is reduced; electromagnetic stirring efficiency of the crystallizer is improved, and superheat of molten steel is quickly dissipated; the isometric crystal rate of a continuous casting blank is increased, and the center segregation defect of the casting blank is reduced. The method is simple and easy to implement and remarkable in effect.

Owner:UNIV OF SCI & TECH BEIJING

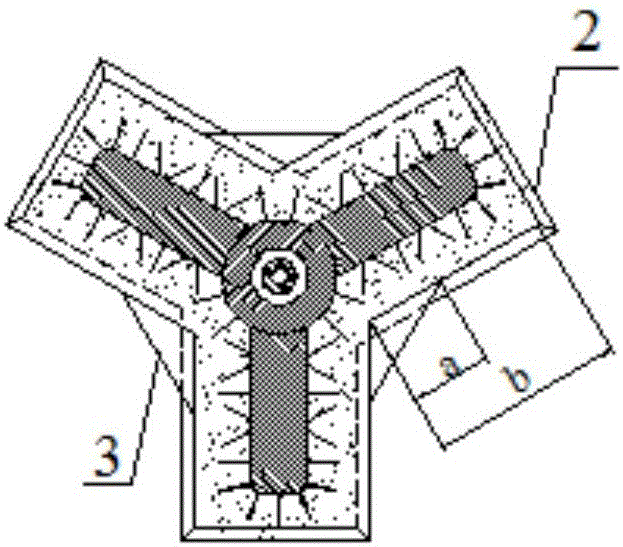

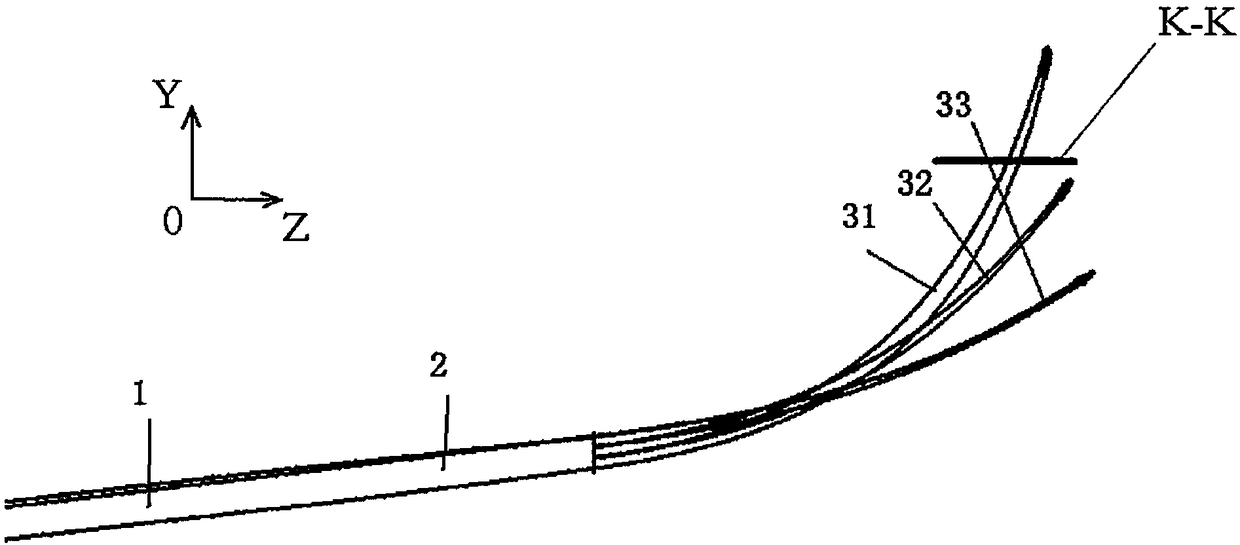

Wingtip devices of airplane wings

ActiveCN106184710AReduce vortex intensityReduced shock intensityDrag reductionHeat reducing structuresAirplaneFront edge

The invention provides wingtip devices of airplane wings. The wingtip devices are symmetrically arranged on wingtip portions of the wings on the two sides of an airplane. At least two wingtip sails are arranged on the outer side of the wingtip portion of the wing on each side. A wingtip sail root of each wingtip sail is in smooth connection with the outer end face of the wingtip portion of the corresponding wing in the length direction of the wing. Each wingtip sail upwards bends and tilts in the length direction of the corresponding wing. The wingtip sail root of each wingtip sail and the outer end face of the wingtip portion of the corresponding wing are sequentially arranged in the width direction of the wing, and the wingtip sail closer to the front edge of the corresponding wing upwards bends and tilts more highly. The fusion type design is adopted, the wingtip sails are in smooth transition connection with the corresponding wings or transition zones, by fully utilizing tight arrangement of the adjacent wingtip sails, air flowing on the upper surfaces of the wingtip sails is slowed down, so that a pressure difference is obtained, and the wingtip vortex intensity is reduced accordingly.

Owner:COMAC +1

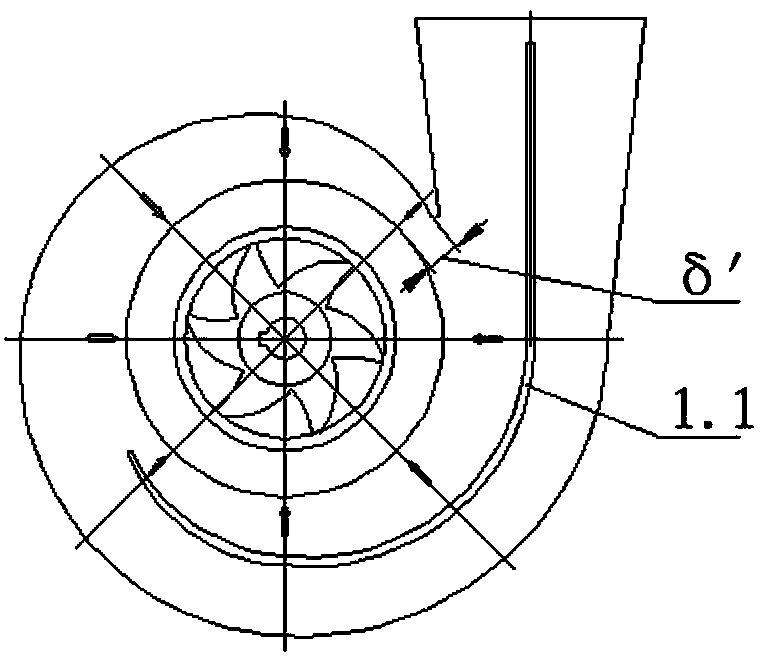

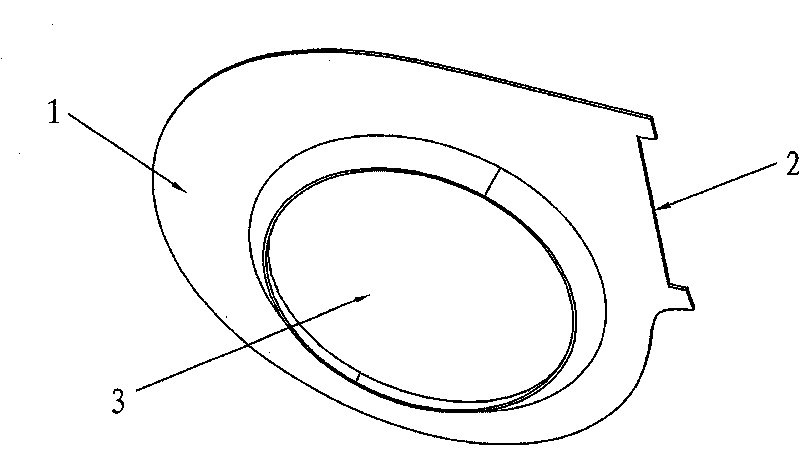

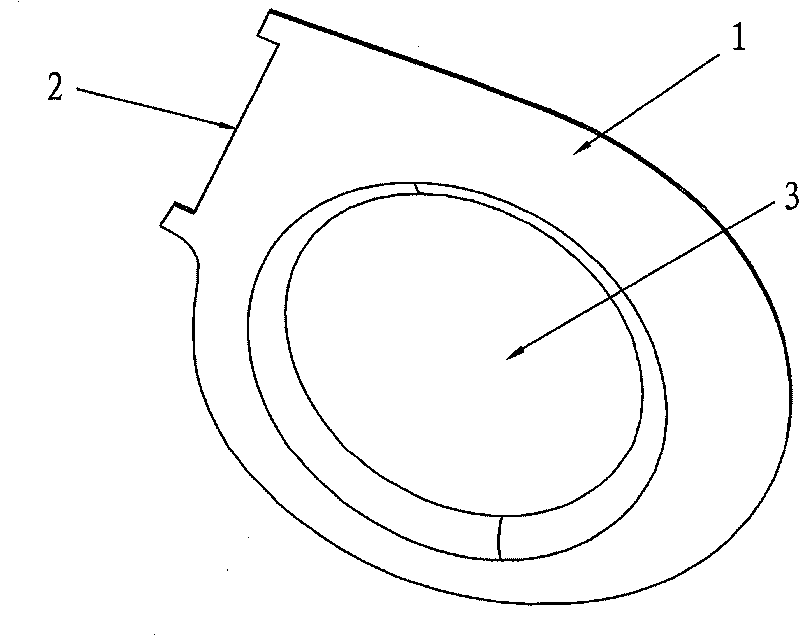

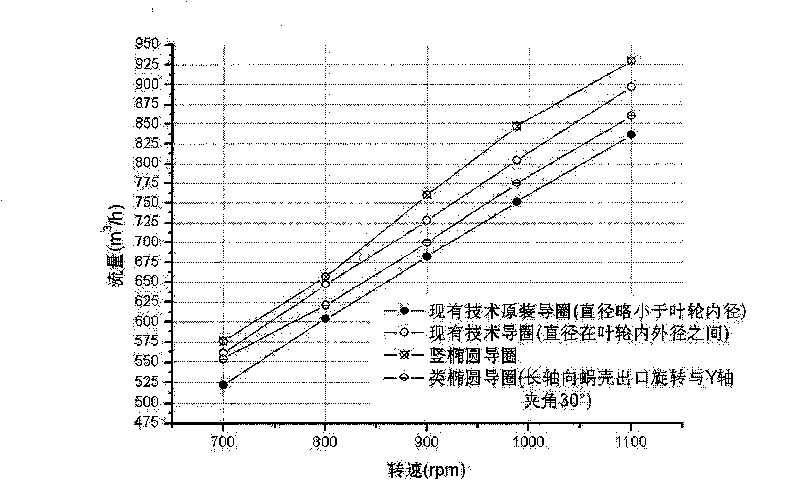

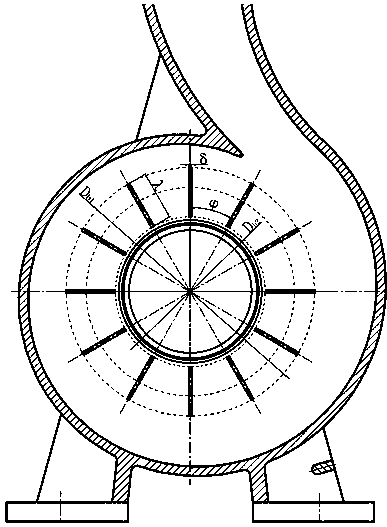

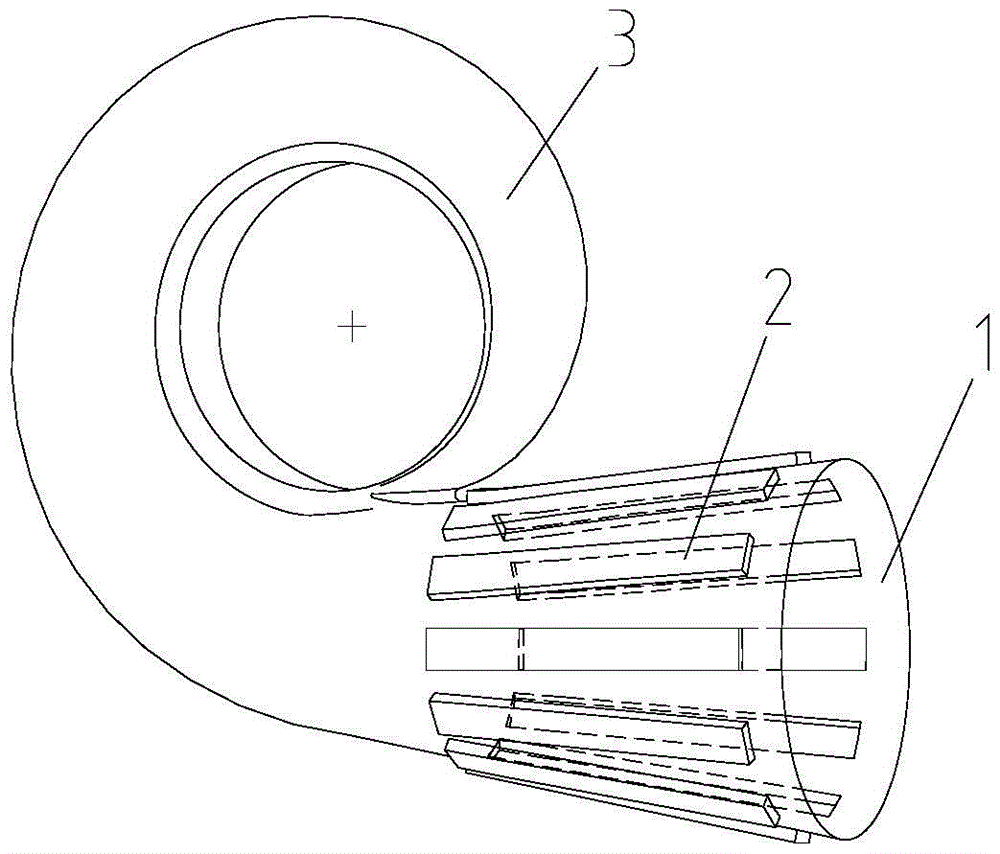

Volute casing of forward curved multi-blades centrifugal fan

The invention relates to a volute casing of a forward curved multi-blades centrifugal fan, comprising a volute plate, a guide ring arranged on the volute plate and an outlet arranged on the volute plate. The volute casing is characterized in that the guide ring is in a like-ellipsoid shape, wherein the short radius of the elliptic guide ring is slightly smaller than or equal to the inner radius of an impeller, and the short radius is close to a volute tongue area. Because the structure of the volute casing can take both the uniformity of inlet air and the vortex intensity of the impeller close to the guide ring into account, the inlet air condition of the volute tongue area is improved, and an area away from the volute tongue and close to the outlet of the volute casing has a better inlet air condition, thus the vortex intensity and fan noise can be reduced. Because the vortex intensity of the impeller close to the guide ring can be reduced and the circumferential uniformity of air flows of an outlet of the guide ring can be improved, through regulating the position of the elliptic guide ring on the circumference of the volute casing, the requirements of effectively reducing the noise and improving the performance of the fan can be conveniently met.

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD +1

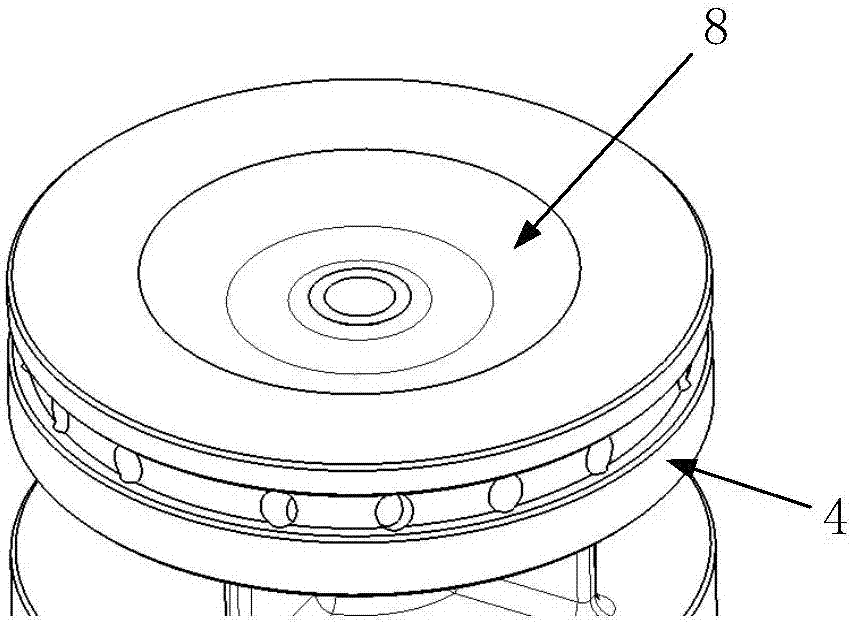

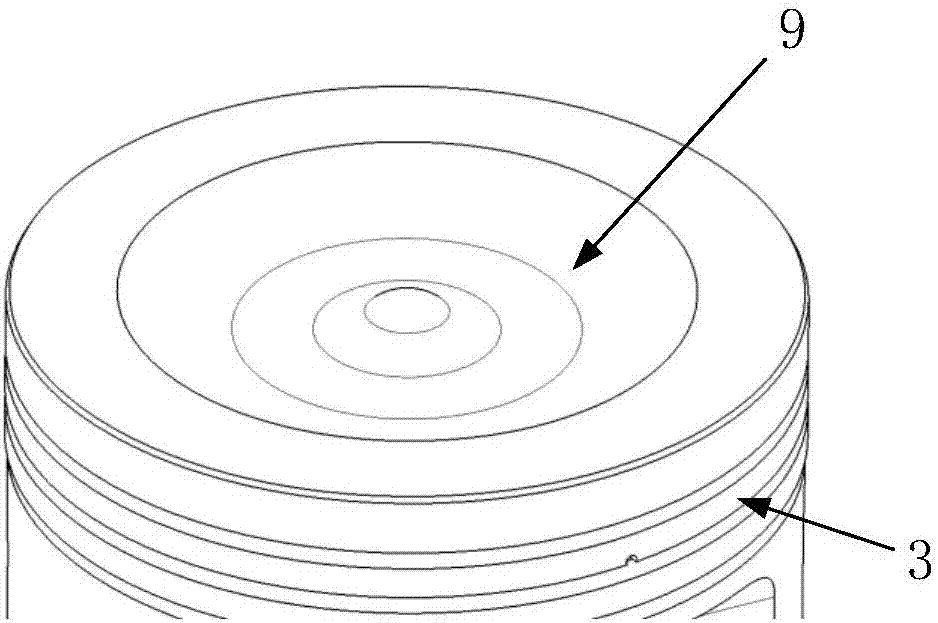

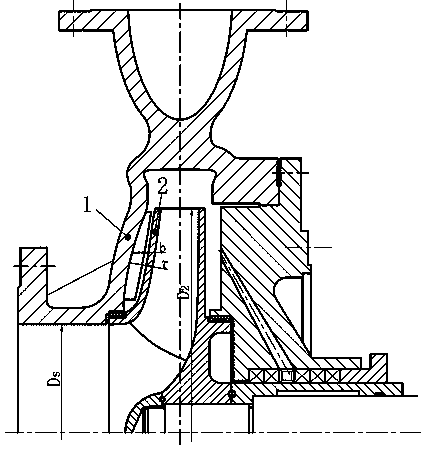

a centrifugal pump

ActiveCN105201903BImprove inflow conditionsImprove working conditionsPump componentsPumpsEngineeringEnergy loss

The invention relates to the field of fluid machinery, particularly a centrifugal pump. The centrifugal pump is characterized in that a front blade for improving the flow properties in the front cavity is arranged between a front pump cover and an impeller front cover plate. The fluid at the impeller exit enters the front blade via the junction between the front cavity and volute casing inlet; the vortex intensity of the fluid is reduced under the action of the front blade, thereby reducing the energy loss and enhancing the efficiency; and the energy of the fluid is lowered after passing through the front blade, and the disturbance generated by mixing with the impeller entrance low-energy fluid is reduced, thereby improving the impeller inflow condition.

Owner:JIANGSU UNIV

Air conditioner air outlet device

PendingCN114593518AGuaranteed comfortEnsure fairnessDucting arrangementsMechanical apparatusAcute angleDrive shaft

The air conditioner air outlet device comprises a plurality of blades, a transmission mechanism, an air pipe barrel, a motor and a decoration ring, the air pipe barrel is of a hollow tubular structure and is provided with an inlet end and an outlet end, the blades are arranged in the air pipe barrel, and the roots of the blades are installed on a transmission shaft of the transmission mechanism; the decorative ring is arranged outside the air pipe barrel and connected with the outlet end, and the decorative ring is opened outwards in a splayed mode in the direction away from the air pipe barrel. During application, the motor drives at least part of the blades to rotate around the transmission shaft through the transmission mechanism, and the relative positions of at least part of the blades can be adjusted, so that the air supply distance can be changed and adjusted to adapt to different application sites, particularly meet the air supply requirement of a high and large space. Particularly, when the acute angle formed by the blade and the blade rotating plane is gradually reduced from the inlet end to the outlet end, the resistance coefficient of the air outlet can be reduced, and the energy consumption of the air conditioner is reduced; in addition, when the front edges of the blades are sawtooth-shaped, the vortex intensity can be weakened, and noise reduction is achieved.

Owner:TROX AIR CONDITIONING COMPONENTS (SUZHOU) CO LTD

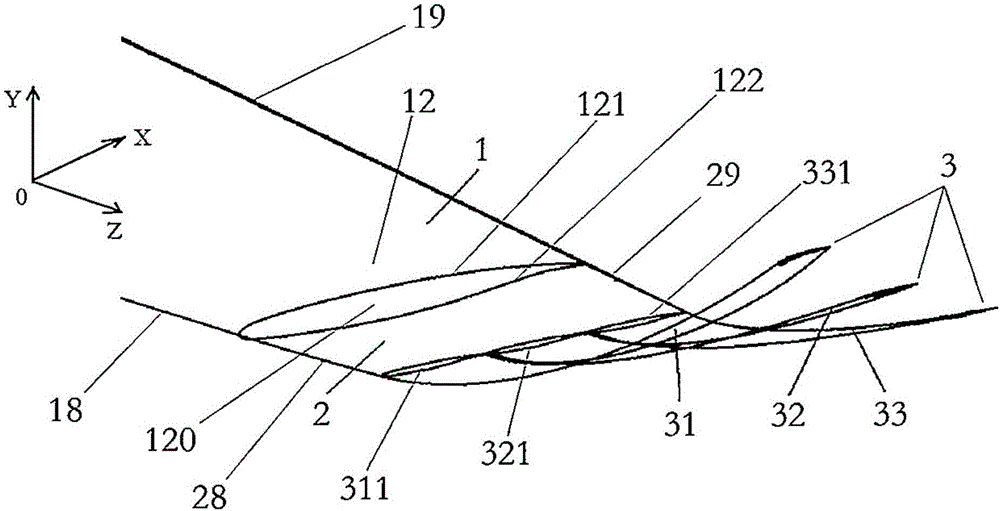

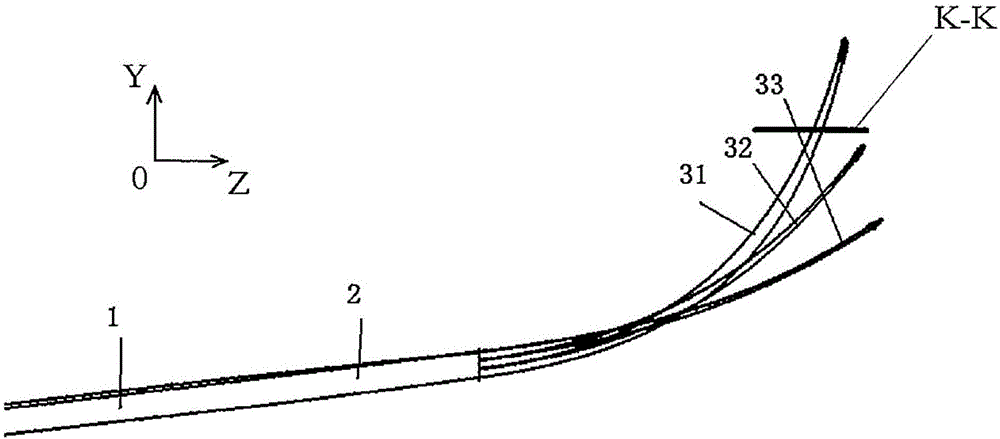

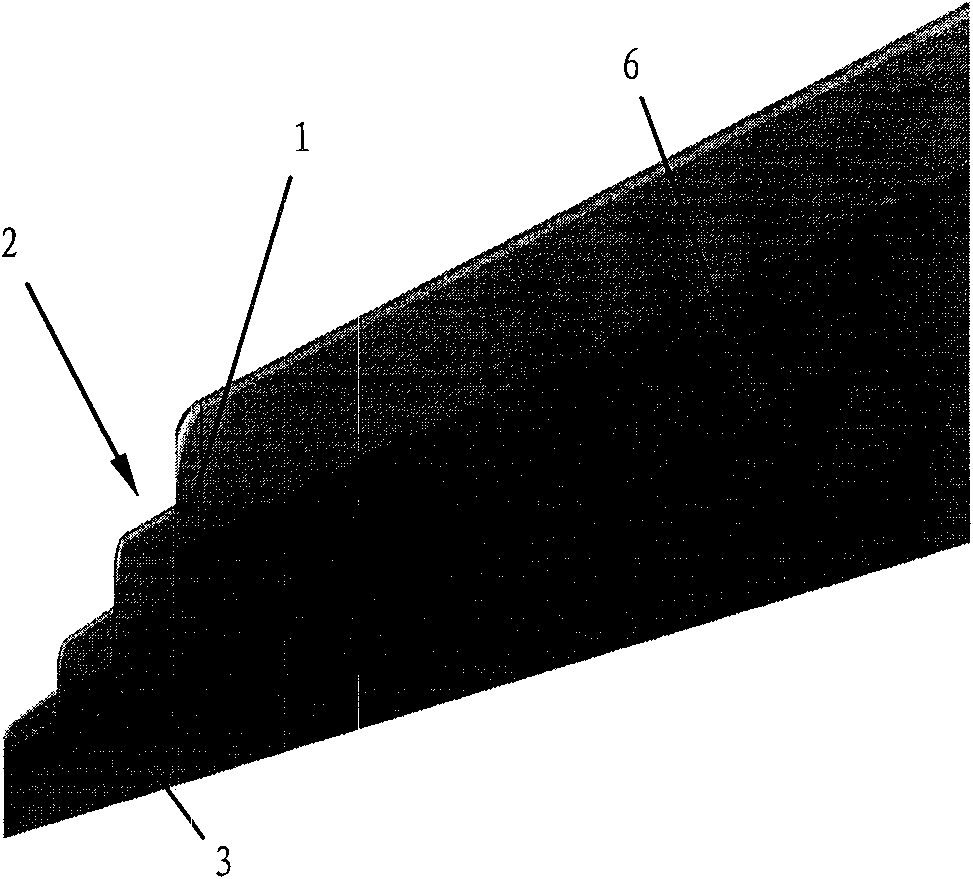

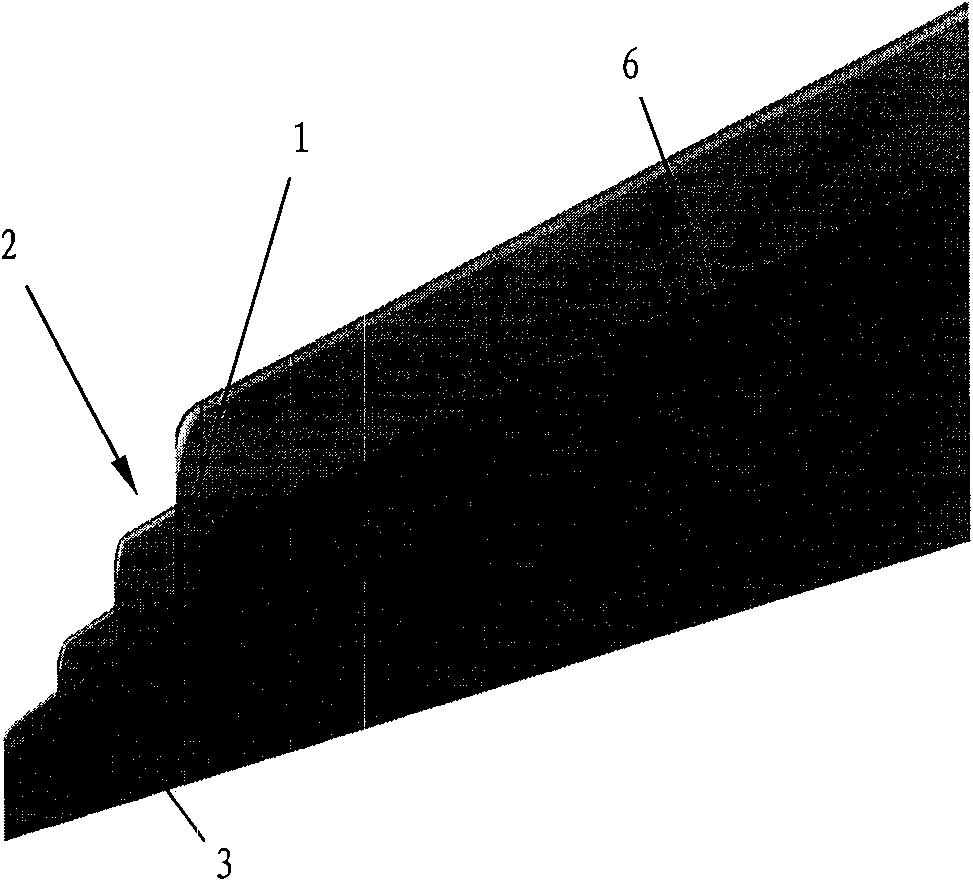

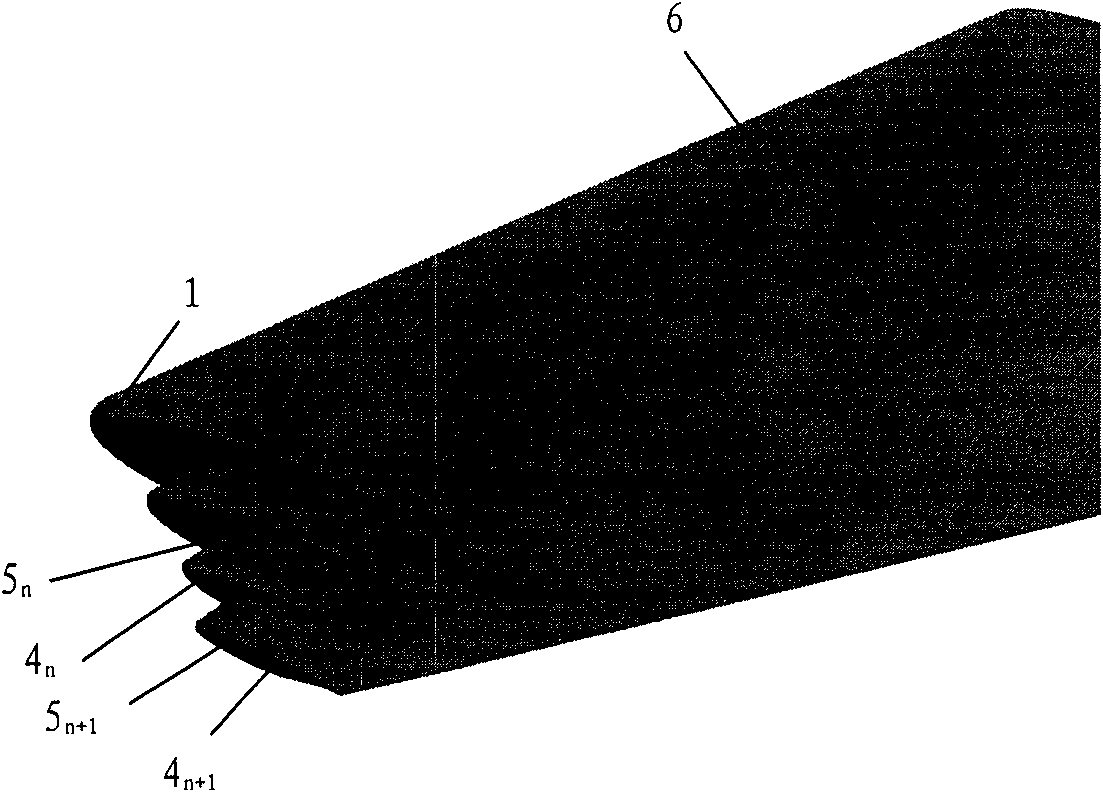

Airplane wingtip device

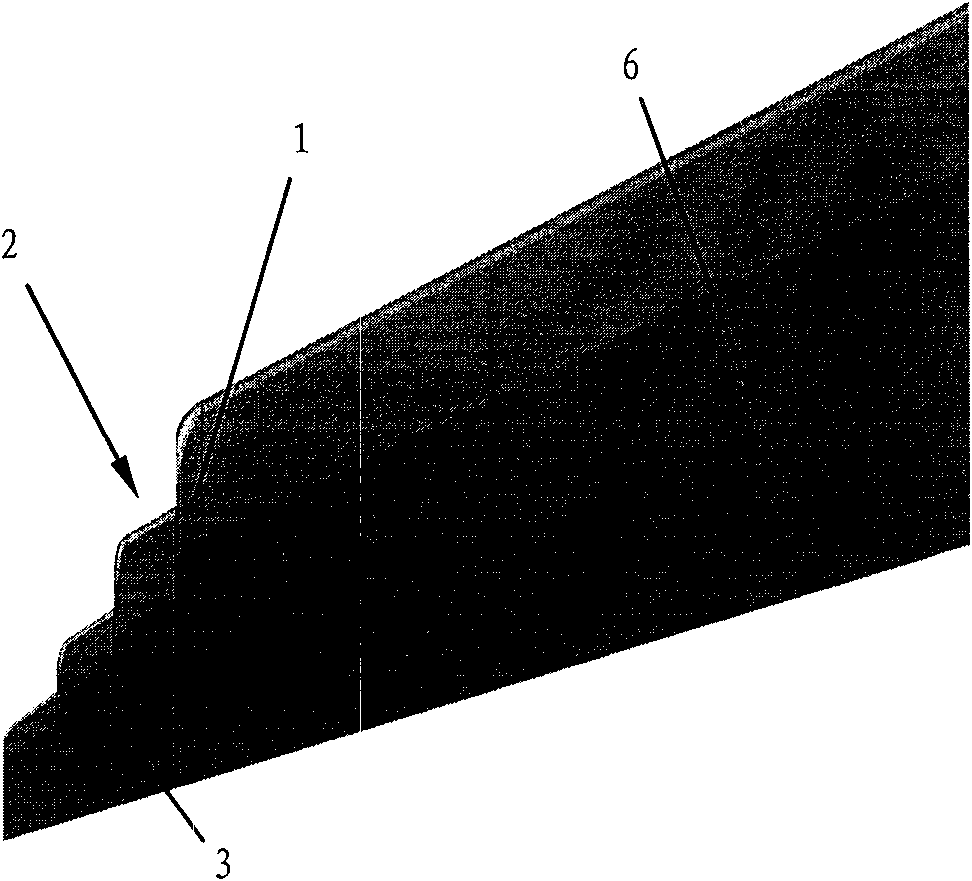

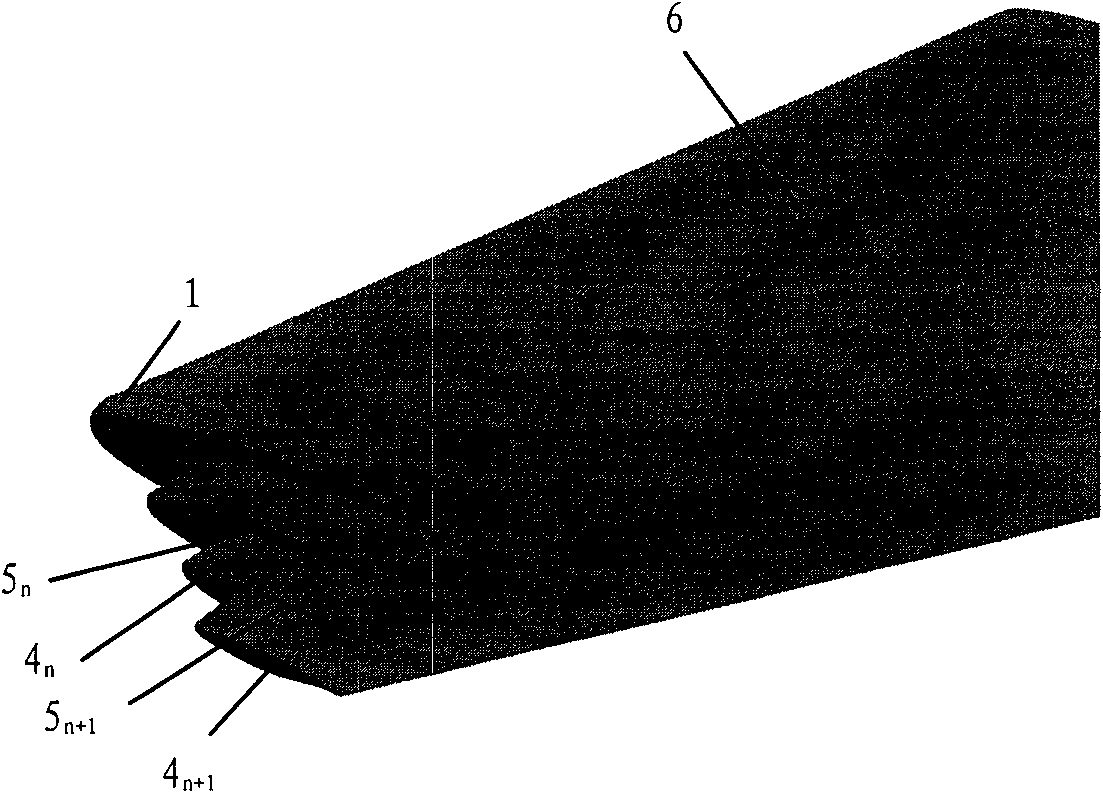

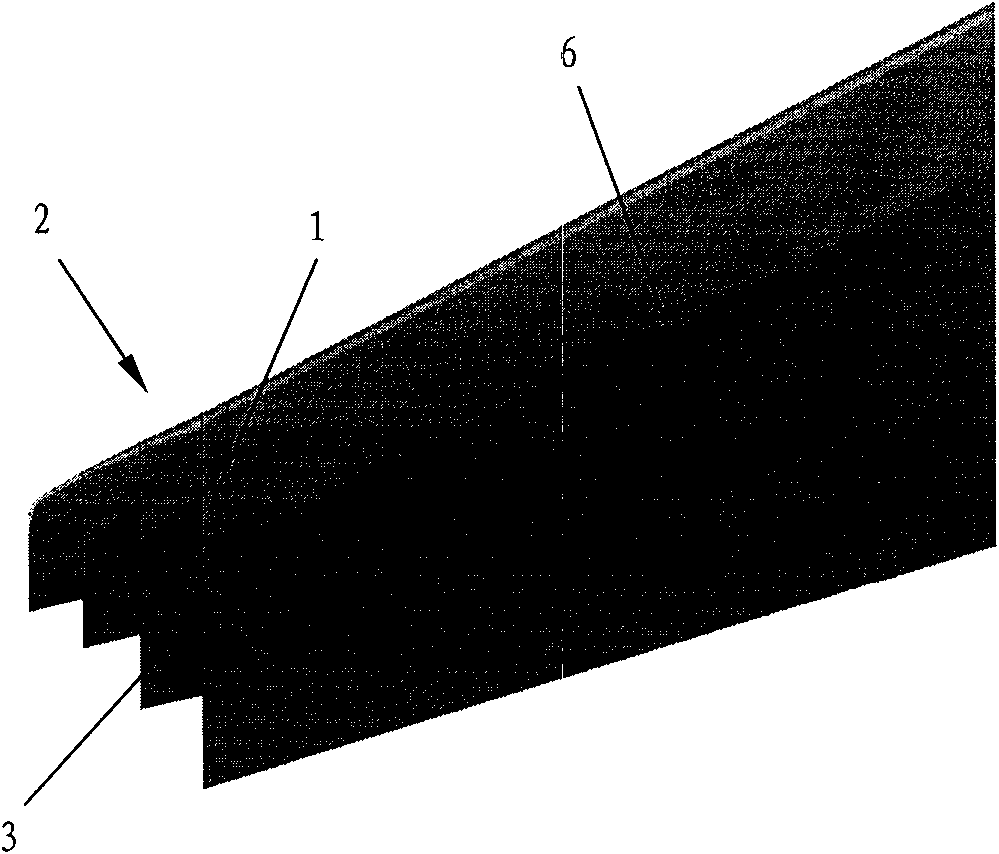

ActiveCN102167154BSmall bending moment incrementReduce structural weightWing shapesHeat reducing structuresLeading edgeWingtip device

The invention provides an airplane wingtip device which comprises a transition part and a wingtip part. The inner end part of the transition part is connected with the far end of an airplane wing, and the outer end part of the transition part is connected with the wingtip part; the wingtip part comprises a plurality of wingtip sections; and each wingtip section comprises a wingtip and a wing root respectively, the wing root of the first wingtip section is connected with the outer end part of the transition part, and arranged between the first edge and rear edge of the outer end part of the transition part, the wing root of the (n+1)th wingtip section is placed on the wingtip of the nth wingtip section, and the wing root chord length of the (n+1)th wingtip section is smaller than the wingtip chord length of the nth wingtip section, wherein n is larger than 0. The wingtip device provided by the invention is arranged in a step shape, so that more than one discontinuity surface is added on each wingtip of the wingtip device, wingtip vortexes induced by the wingtips are mutually inhibited, the vortex intensity is weakened, and the effect of reducing resistance is achieved. In addition, the wing root bending moment increment is smaller, the structural weight of an airplane is reduced, and the influence on the flutter characteristic is smaller as well.

Owner:COMAC +1

Collision spray vortex chamber of internal combustion engine

InactiveCN1304749CReduce vortex intensityEmission reductionInternal combustion piston enginesFuel re-atomisation/homogenisationCombustorExternal combustion engine

The present invention is collision atomizing eddy current chamber for internal combustion engine and belongs to the field of mixed gas formation and combustion in internal combustion engine. The colliding stage set inside the eddy current chamber makes the primary oil beam jetted from the oil nozzle form fast even fine secondary oil beam, and the comprehensive effects of the secondary oil beam and air eddy current inside the eddy current chamber form excellent inflammable gas mixture resulting in fast and perfect combustion. The area of the connecting channel between the main combustor and the eddy current chamber is increased to lower the eddy current strength inside the eddy current chamber. The present invention results in raised economic performance, improved cold starting performance and load adaptability and obvious reduced lower-load carbon smoke exhaust, while maintaining the available compression ratio.

Owner:DALIAN UNIV OF TECH

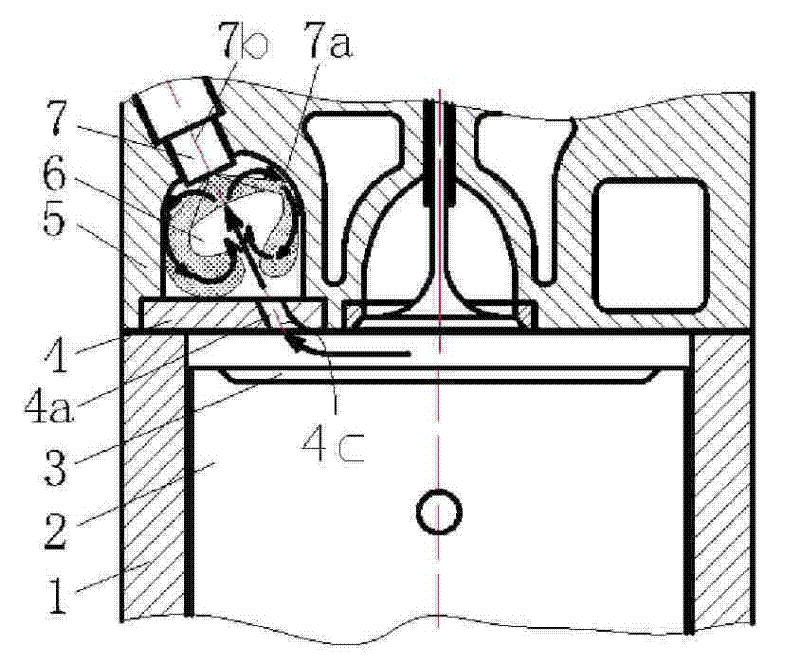

Vortex chamber combustion system utilizing umbrella-shaped spray

InactiveCN101655029BWell mixedEfficient mixingInternal combustion piston enginesCombustion systemEngineering

The invention relates to a vortex chamber combustion system utilizing umbrella-shaped spraying, which belongs to the fields of formation and combustion of engine mixing gases. The vortex chamber combustion system utilizing an oil nozzle with an umbrella-shaped spraying has the structural characteristics that the center line of the oil nozzle with an umbrella-shaped spraying way is superposed withthe center line of a main passage so that the air which flows into a vortex chamber from a compression stroke via the main passage turns back along the wall surface of the vortex chamber to form vortex after reaching the vicinity of the head part of the oil nozzle; the direction of the vortex is just along the diffused direction of the umbrella-shaped spraying so as to accelerate oil and gas mixture and improve the combustion. Because the characteristics of short penetrating distance, even circumferential distribution and high granulation of the umbrella-shaped spraying are reasonably utilized, the favorable mixture and combustion can be obtained at lower vortex strength, thereby reducing heat dissipation loss and throttling loss and further improving the heat efficiency of an engine. Experiments on a single-cylinder 195 diesel engine indicate that the power is improved by 10 percent, the oil consumption is reduced by 8 percent, the discharge of NOx is reduced by 10 percent and the discharge of soot is reduced by 20 percent after the vortex chamber combustion system utilizing the oil nozzle with a umbrella-shaped spraying way is adopted.

Owner:DALIAN UNIV OF TECH

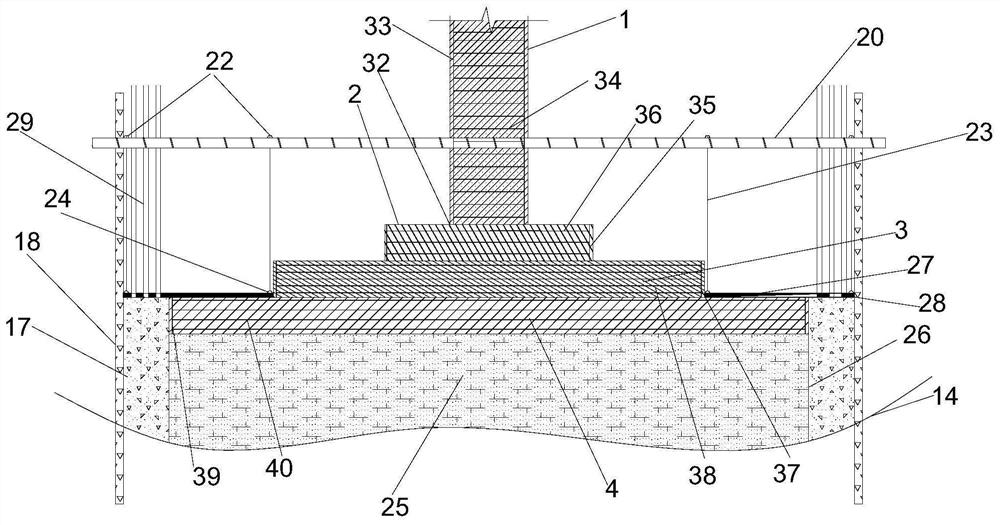

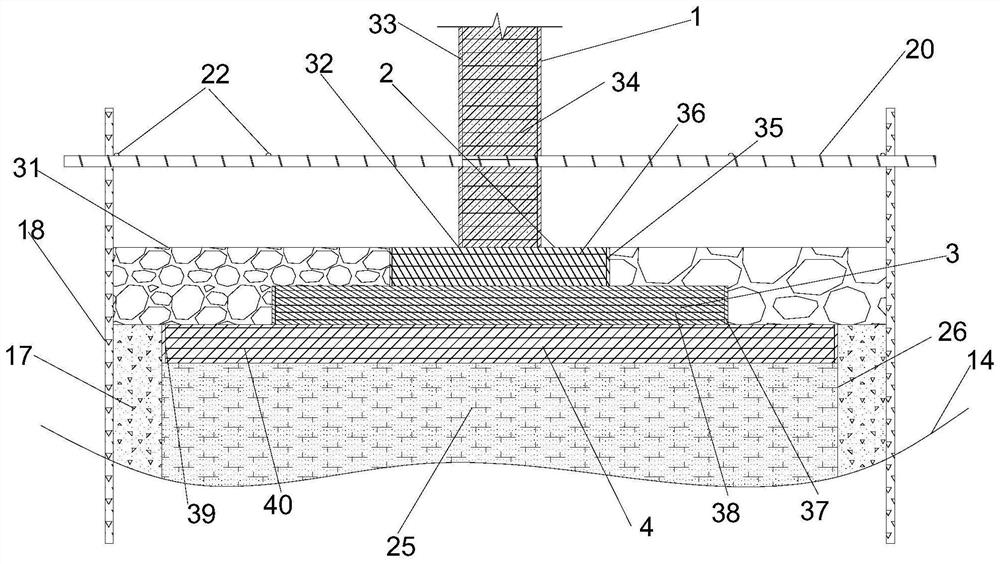

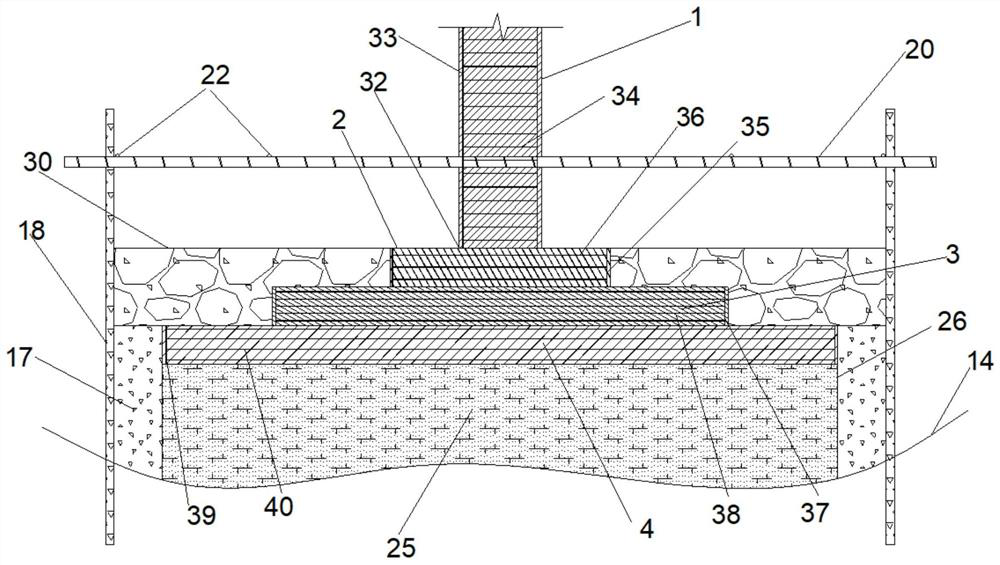

Protection structures of bridge abutment fascines and scour sheet piles and construction method

ActiveCN112195951AStrong ability to adapt to terrainEasy constructionBridge structural detailsBridge erection/assemblyCrushed stoneSlurry

The invention relates to protection structures of bridge abutment fascines and scour sheet piles. The protection structures comprise fascines, gravel stiffening cores, a frame type bottom plate with anchoring piles, anchoring piles, a steel wire net, a bottom grouting slurry separation plate, grouting concrete, longitudinal enclosing sheet piles, transverse enclosing sheet piles, transverse ring beams, longitudinal ring beams, suspension steel wire ropes, grouting slurry separation plates on the periphery of a bearing platform, rubble concrete and rubbles. When a bearing platform foundation ofa bridge is slightly scoured, a protection structure of gravel stiffening core fascine peripheral press is adopted, and when the bearing platform foundation of the bridge is heavily scoured, a protection structure of the scour sheet piles is adopted. The anchoring piles distributed at equal intervals are arranged on the lower portion of the frame type bottom plate with the anchoring piles, and the gravel stiffening cores are bound into a whole through the fascines and placed above the frame type bottom plate with the anchoring piles of the bearing platform foundation in bundles to form peripheral protection. The protection structures of the bridge abutment fascines and the scour sheet piles have the advantages that the adopted fascine protection is high in terrain adaptability, construction is easy, materials are convenient to obtain, the structural integrity is enhanced through enclosure of the steel wire net, and the anti-scouring capacity is improved.

Owner:浙江世润建创科技发展有限公司

Airplane wingtip device with aligned front edge

ActiveCN102167152BSmall bending moment incrementReduce structural weightWing shapesDrag reductionWingtip deviceFront edge

The invention provides an airplane wingtip device with an aligned front edge, which comprises a transition part and a wingtip part, wherein the inside end of the transition part is connected with the far end of an airplane wing, the outside end of the transition part is connected with the wingtip part, the wingtip part comprises a plurality of wingtip segments, each wingtip segment comprises a wingtip and a wing root, the wing root of the first wingtip segment is connected with the outside end of the transition part and is aligned with the front edge at the outside end of the transition part, the wing root of the (n+1)th wingtip segment is arranged on the wingtip of the nth wingtip segment, and the wing root chord length of the (n+1)th wingtip segment is less than or equal to the wingtip chord length of the nth wingtip segment, wherein n is more than 0. The wingtip device is step-shaped, so that each wingtip is additionally provided with at least one of discontinuity surfaces, the wingtip vortexes induced by the wingtips are restrained with one another, and the vortex intensity is reduced, therefore the airplane wingtip device achieves a damping effect; and the bending moment incremental quantity of each wing root is less, so that the structural weight of the airplane is reduced, and the influence on the buffeting characteristic is less.

Owner:COMAC +1

Centrifugal pump pressure water chamber for suppressing eddy current and centrifugal pump with same

ActiveCN104329293BImprove running stabilityEasy to processPump componentsPumpsPump chamberEngineering

The invention discloses an eddy current confinement centrifugal pump pumping chamber and a centrifugal pump with the same. In the eddy current confinement centrifugal pump pumping chamber, jet grooves are uniformly formed in the inner wall of a diffusing section of the pumping chamber along the circumference; the length direction of the jet grooves is parallel to the flow line of the diffusing section of the pumping chamber. The jet groove structure produces a micro jet by using adverse pressure gradient in the diffusing section of the pumping chamber, and the micro jet is mixed with a main flow in the diffusing section of the pumping chamber to reduce the eddy current intensity in the diffusing section and confine eddy current development in the diffusing section, so that the stability for operation of the centrifugal pump is improved; meanwhile the micro jet has extremely small influence on the main flow in the diffusing section of the pumping chamber and also has extremely influence on the operation efficiency of the centrifugal pump. The eddy current confinement centrifugal pump pumping chamber has a simple structure, is easy to machine and manufacture and is applicable to any type of centrifugal pump.

Owner:TSINGHUA UNIV

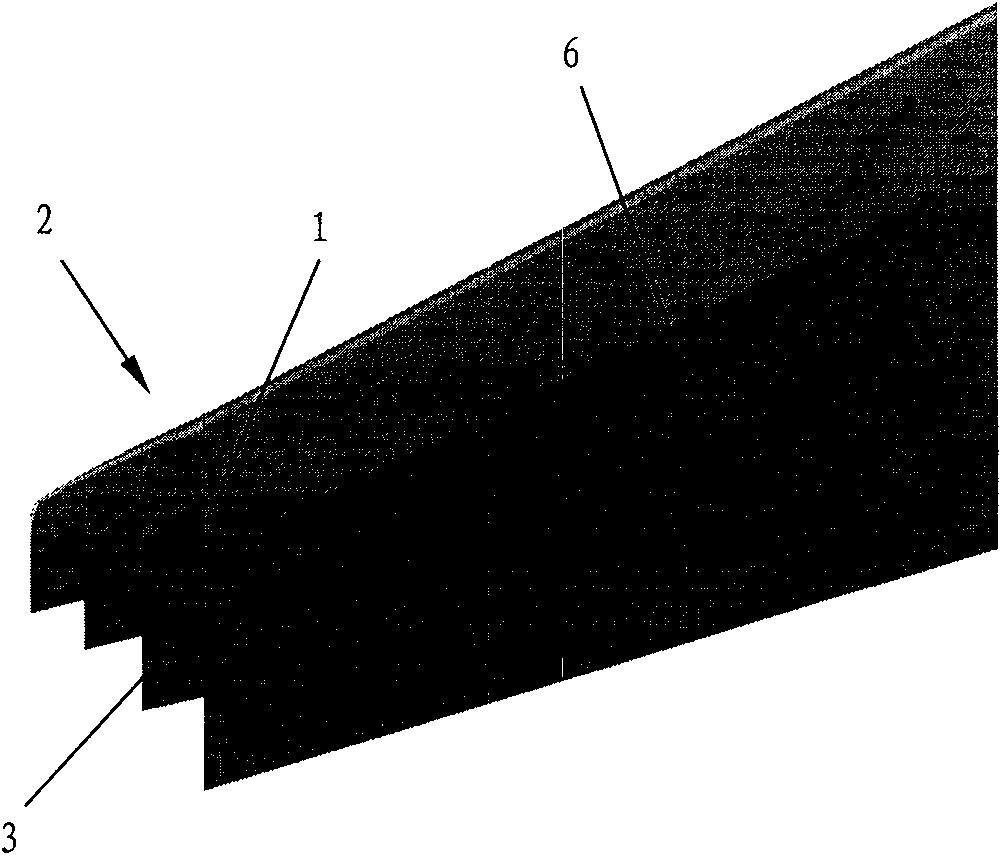

Airplane wingtip device with aligned back edges

ActiveCN102167153BSmall bending moment incrementReduce structural weightWing shapesHeat reducing structuresJet aeroplaneWingtip device

The invention discloses an airplane wingtip device, which comprises a transition part and a wingtip part, wherein the end part of the inner side of the transition part is connected with the far end of an airplane wing; the end part of the outer side of the transition part is connected with the wingtip part; the wingtip part comprises a plurality of wingtip sections; each wingtip section comprises a wingtip and a wing root respectively; the wing root of the first wingtip section is connected with the end part of the outer side of the transition part, and is aligned with the back edge of the end part of the outer side of the transition part; the wing root of the (n+1)th wingtip section is positioned on the wingtip of the nth wingtip section; the chord length of the wing root of the (n+1)th wingtip section is smaller than or equal to that of the wingtip of the nth wingtip section; and n is more than 0. The wingtip device disclosed by the invention is arranged in a step form, and each wingtip is provided with more than one discontinuity surface, so that wingtip vortexes induced from the wingtips suppress one another, the vortex intensity is weakened, and the resistance reducing effect is achieved; moreover, the bending moment increment of the wing roots is smaller, so that the structural weight of the airplane is lightened, and the influence on flutter characteristic is smaller.

Owner:COMAC +1

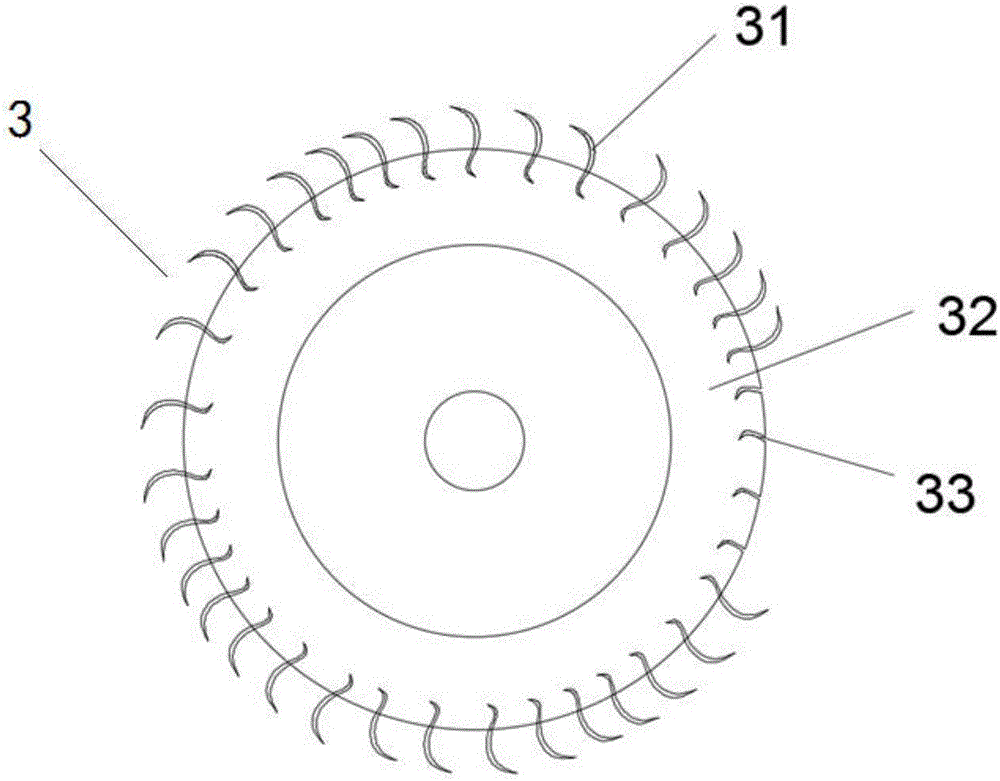

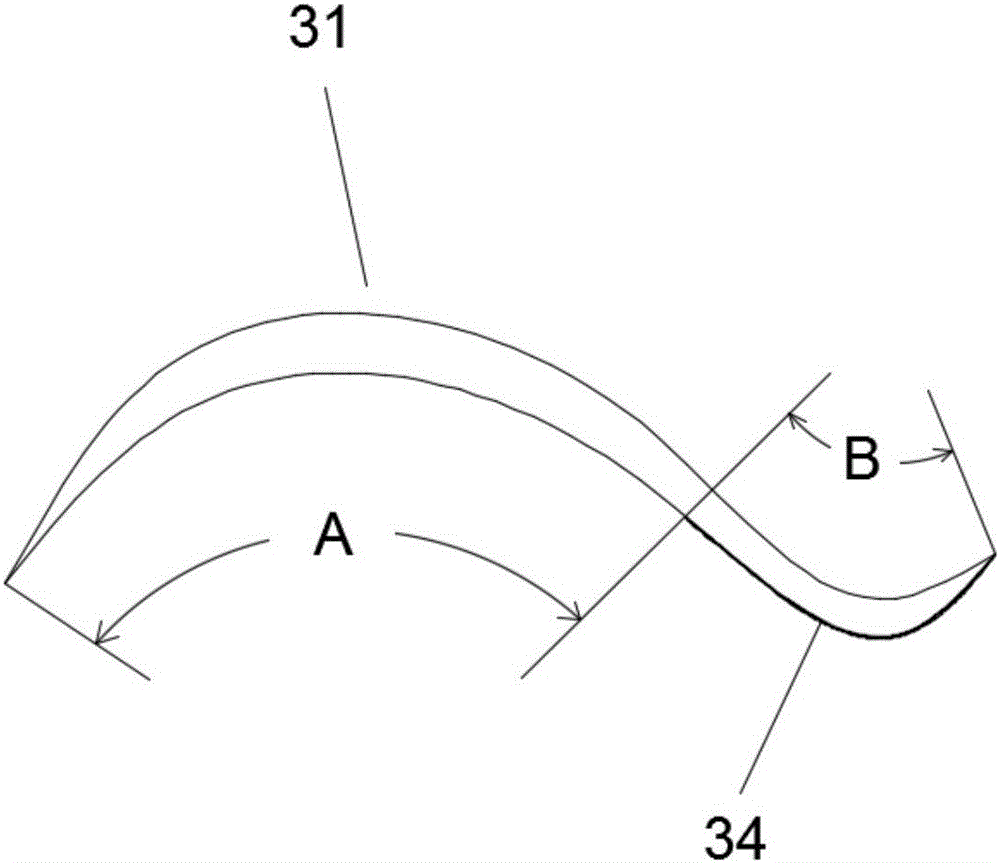

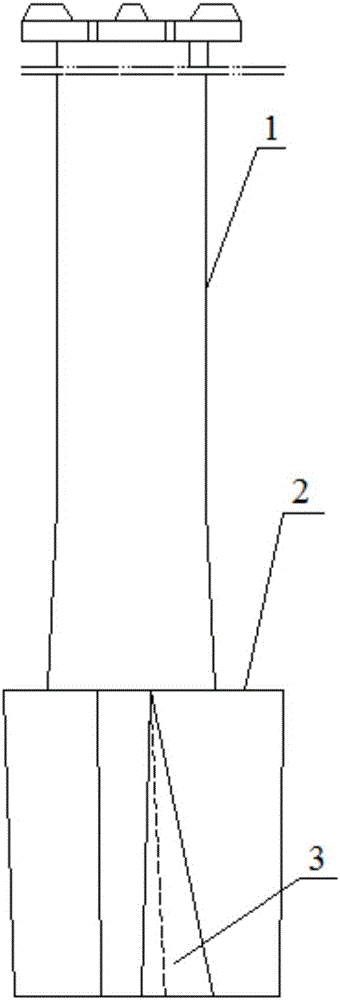

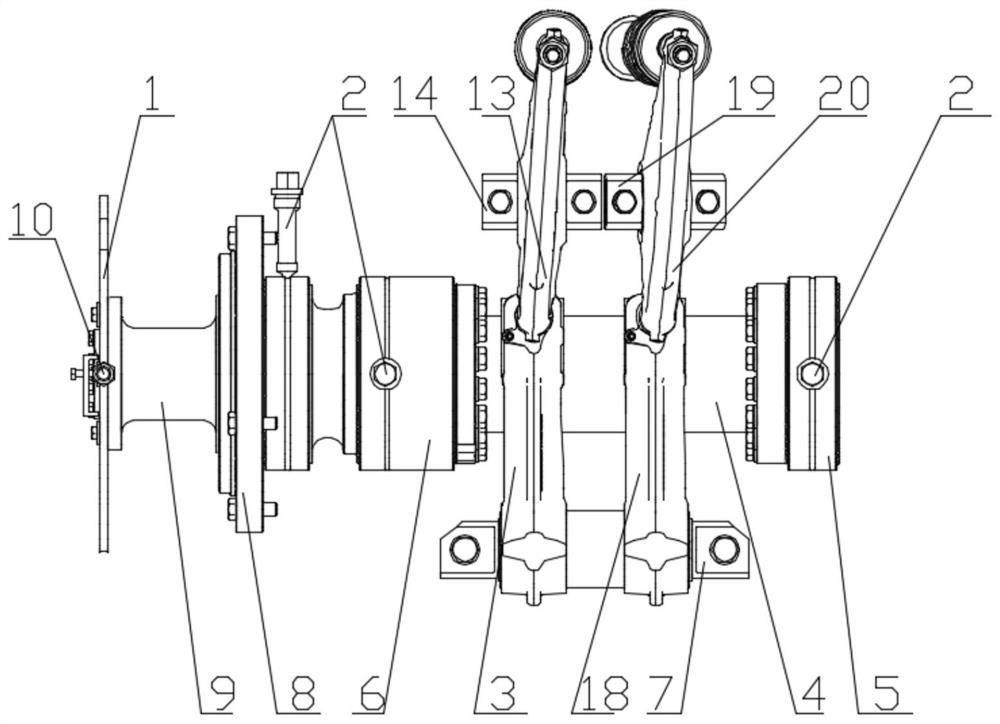

Molten iron desulfurization stirrer

InactiveCN106086313AIncrease the angleIncrease the areaRotary stirring mixersTransportation and packagingSlag

The invention discloses a molten iron desulfurization stirrer. The molten iron desulfurization stirrer comprises a rotating shaft, and multiple stirring blades fixed on the outer peripheral edge of the rotating shaft and uniformly distributed in the peripheral direction of the rotating shaft; flow conductors are lined between two adjacent stirring blades, and are formed by surrounding triangular bottom surfaces and side surfaces outwards extending along each edge of the triangular bottom surfaces; one side surfaces of the flow conductors are bonded with the surfaces of one of two adjacent stirring blades; and the other side surfaces of the flow conductors are bonded with the surfaces of the other one of two adjacent stirring blades. The molten iron desulfurization stirrer is simple in structure and convenient for manufacturing, prominently improves the dynamic conditions of molten iron mechanical stirring desulfurization, prolongs the service life, and reduces the slag bonding between the stirring blades.

Owner:武汉钢铁有限公司

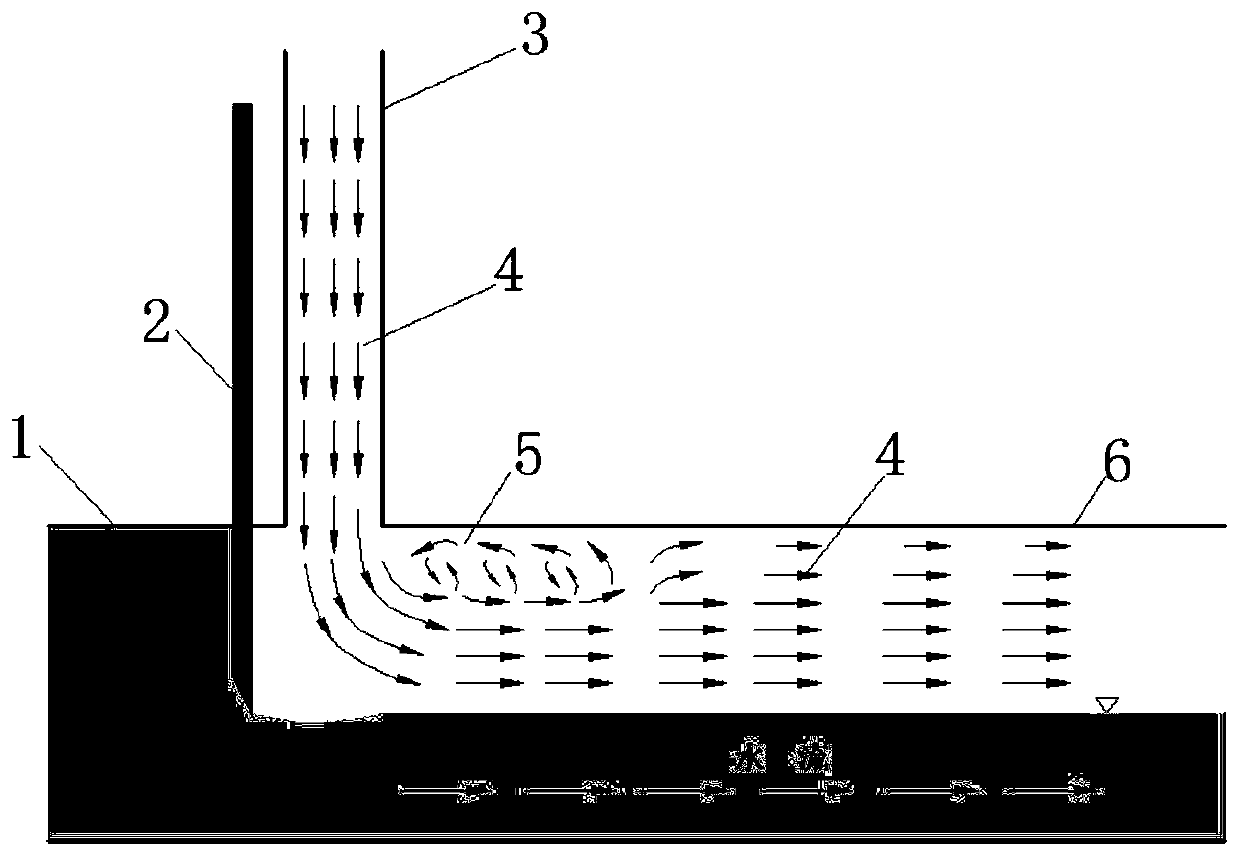

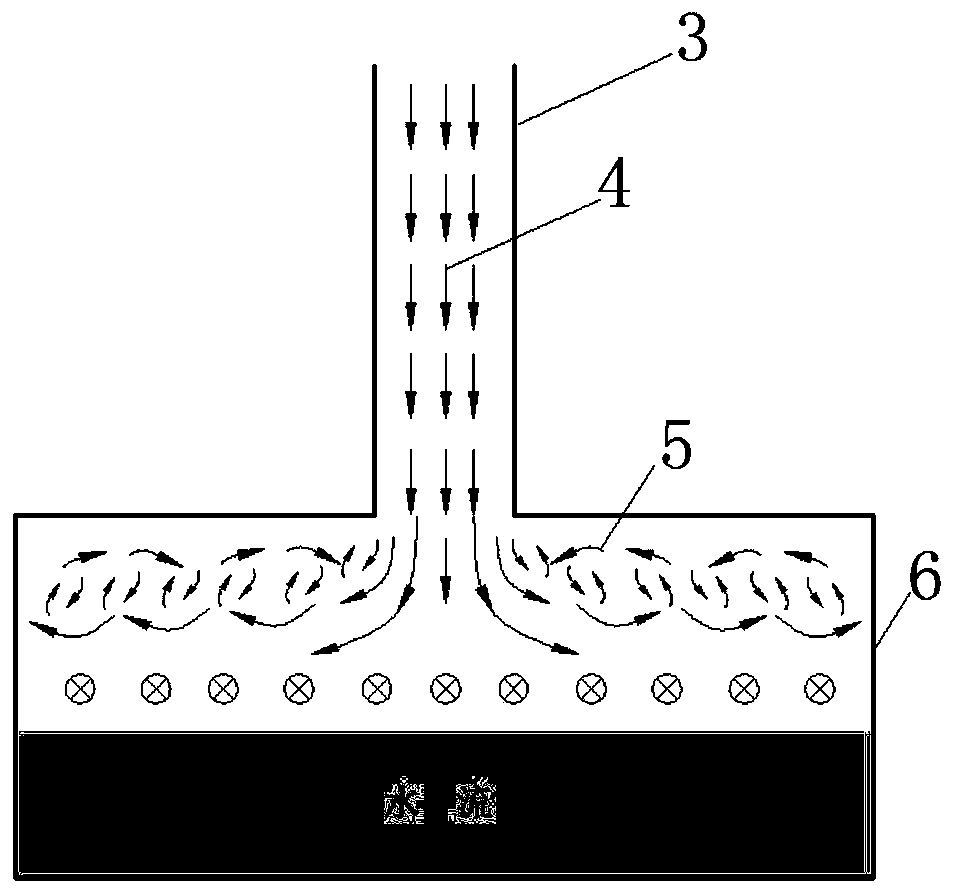

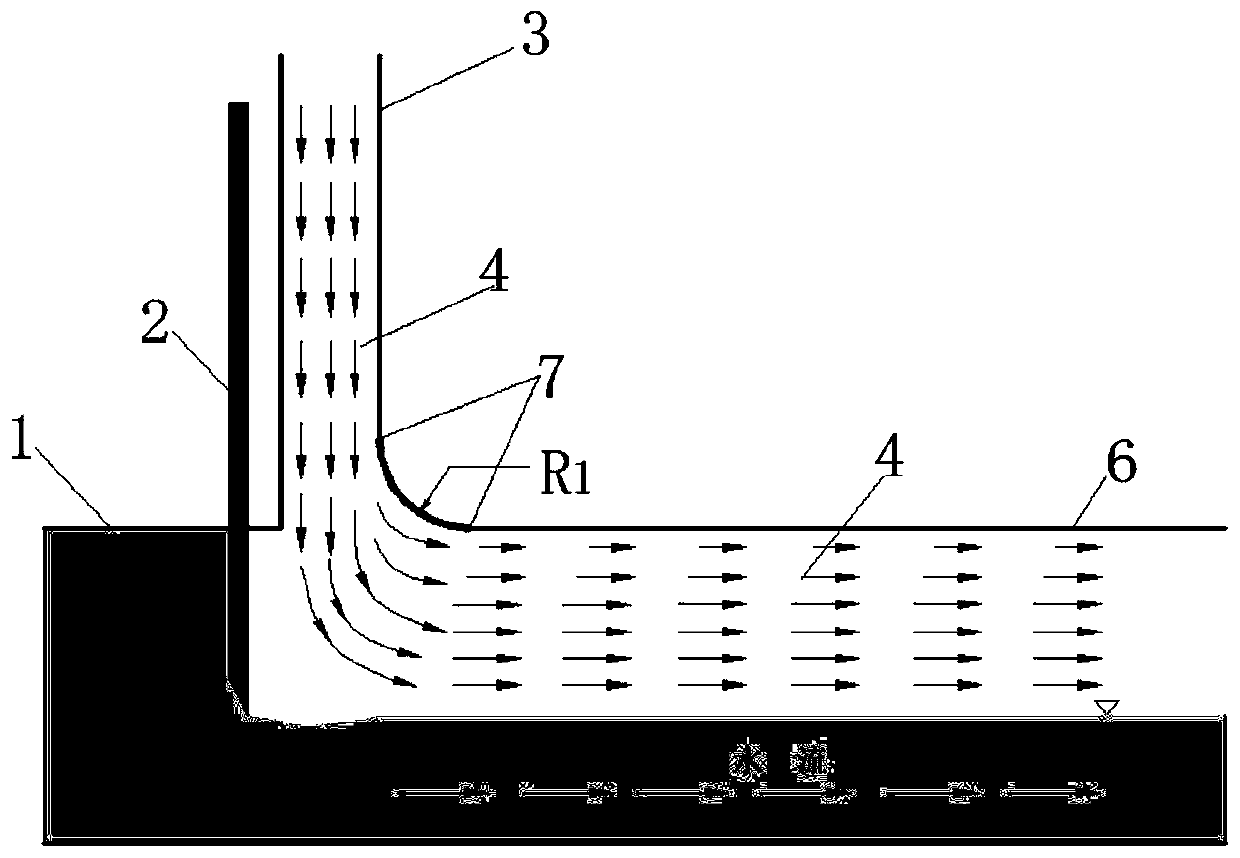

A diversion structure for ventilation and air supply facilities in open flow flood discharge tunnels

The invention discloses a flow guide structure of a ventilating and air supplementing facility of an open flow flood discharge tunnel. An arc flow guide ridge (7) used for guiding air flow to enter the open flow flood discharge tunnel is arranged at the connecting part between a ventilating and air supplementing facility and the open flow flood discharge tunnel (6), the arc length of the arc flowguide ridge is one fourth arc, and the radius of the arc is determined according to the maximum wind speed in the ventilating and air supplementing facility under the maximum flood discharge flow. Theventilating and air supplementing facility and the open flow flood discharge tunnel (6) are connected through the arc flow guide ridge, the flow direction of the air flow at the connecting part between the ventilating and air supplementing facility and the open flow flood discharge tunnel under the condition of high ventilation and wind speed can be smoothed, local position airflow vortexes are eliminated, the ventilating and air supplementing effects of the ventilating and air supplementing facility are improved, and strong noise generated due to the fact that the local air flows in an adverse flow state is avoided, the operation safety of the flood discharge tunnel of the water conservancy project and the production and living environment of workers are guaranteed.

Owner:SICHUAN UNIV +2

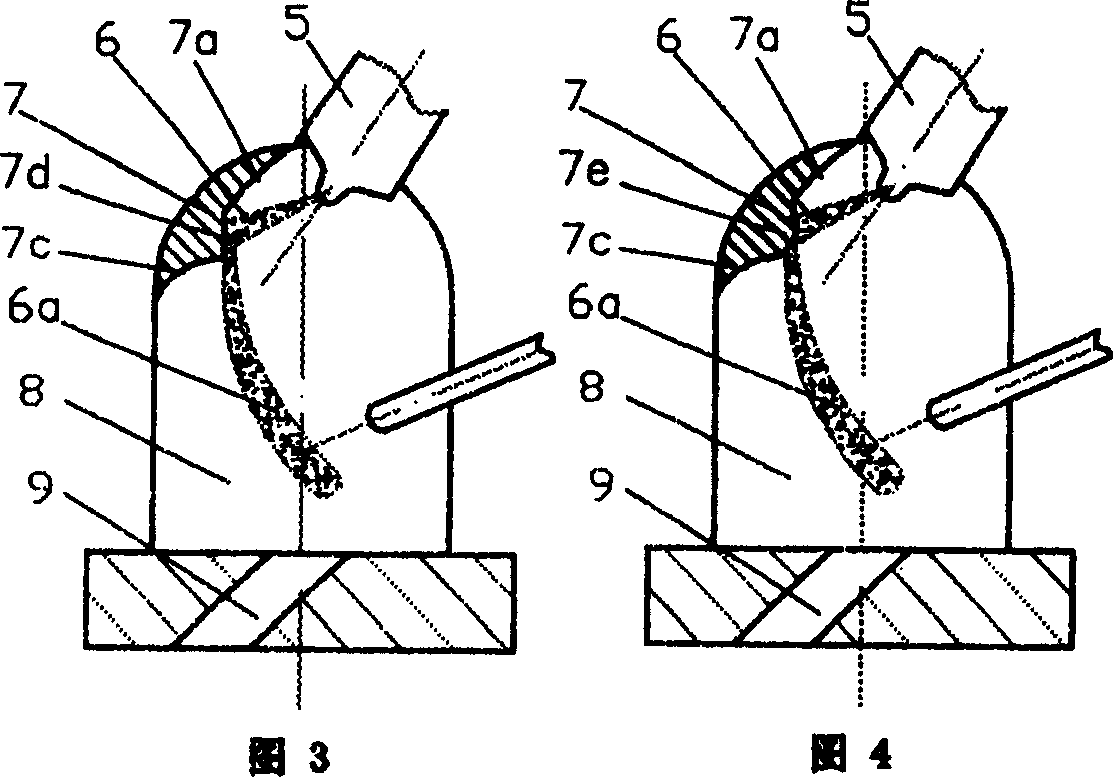

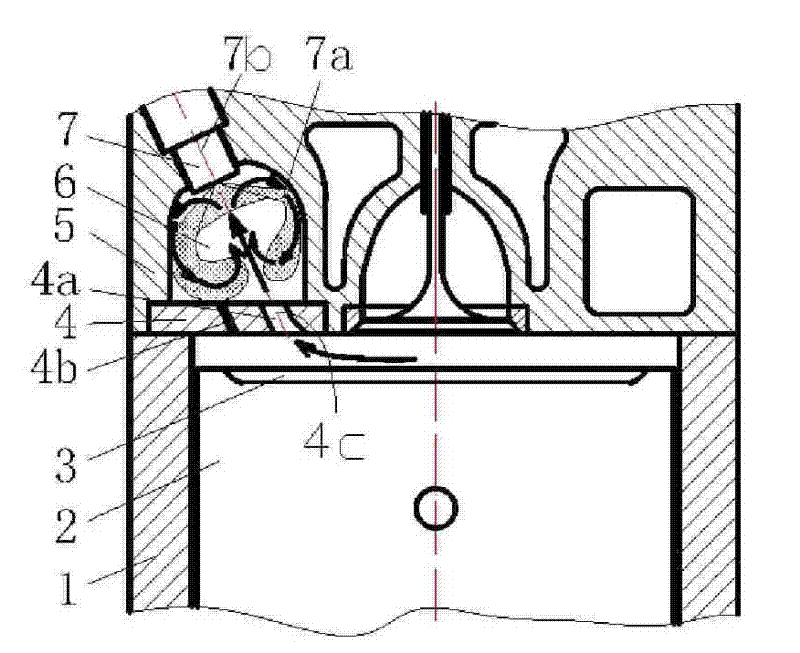

A horizontal intake and exhaust gas distribution device

ActiveCN113464231BSolve the problem that is difficult to meet the combustion experimentImprove air intake efficiencyCylinder headsCylindersExhaust valveTop dead center

The invention provides a horizontal intake and exhaust gas distribution device, which belongs to the field of engine gas distribution mechanisms. It solves the problem that the existing arrangement of intake and exhaust valves is difficult to meet the combustion experiment. It consists of intake cams and exhaust cams mounted on the camshaft, the intake cams and exhaust cams are in contact with the intake cam follower and exhaust cam follower respectively, the intake cam follower and the exhaust cam The bottom of the follower is connected to the driven shaft in rotation, the upper part of the intake cam follower is connected to the bottom of the intake rocker arm through the intake push rod, and the middle part of the intake rocker arm is connected to the intake rocker shaft. The upper part of the rocker arm is connected with the intake valve, and the upper part of the exhaust cam follower is connected with the bottom of the exhaust rocker arm through the exhaust push rod. The intake valve and the exhaust valve are horizontally arranged perpendicular to the piston running direction. The arrangement is located below the cylinder head and above the top dead center of the piston. It is mainly used for gas distribution of the engine.

Owner:HARBIN ENG UNIV

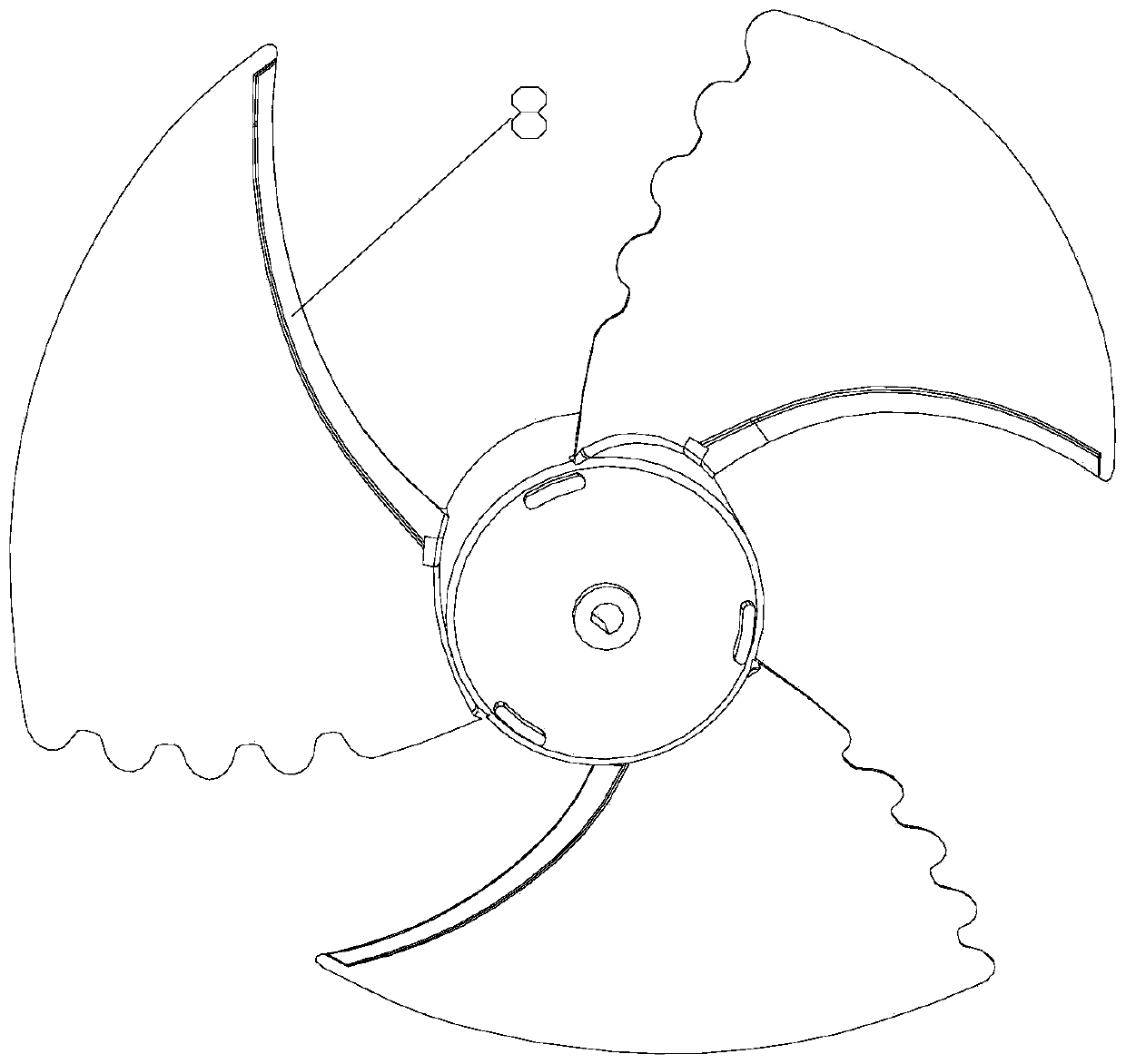

Fan structure

ActiveUS10808726B2Destroying productReduce vortex intensityRotary propellersPump componentsImpellerNoise

A fan structure includes a frame body and a fan impeller. The frame body has a base seat and an annular wall. A bearing cup upward extends from a center of the base seat. At least one groove is annularly formed on inner wall face of the annular wall. The fan impeller is pivotally disposed in the bearing cup and has a hub and multiple blades outward extending from the hub. Each blade has an end edge. At least one protrusion section outward protrudes from the end edge into the groove. According to the design of the fan structure, the protrusion section can destroy the production of the vortex of the blade of the conventional fan so as to greatly minify the strength of the vortex. Therefore, the structure of the sound field of the vortex is changed so that the noise of the fan structure is lowered.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Wingtip device for aircraft wing

ActiveCN106184710BReduce vortex intensityReduce shock intensityDrag reductionHeat reducing structuresAircraft landingWingtip device

The invention provides wingtip devices of airplane wings. The wingtip devices are symmetrically arranged on wingtip portions of the wings on the two sides of an airplane. At least two wingtip sails are arranged on the outer side of the wingtip portion of the wing on each side. A wingtip sail root of each wingtip sail is in smooth connection with the outer end face of the wingtip portion of the corresponding wing in the length direction of the wing. Each wingtip sail upwards bends and tilts in the length direction of the corresponding wing. The wingtip sail root of each wingtip sail and the outer end face of the wingtip portion of the corresponding wing are sequentially arranged in the width direction of the wing, and the wingtip sail closer to the front edge of the corresponding wing upwards bends and tilts more highly. The fusion type design is adopted, the wingtip sails are in smooth transition connection with the corresponding wings or transition zones, by fully utilizing tight arrangement of the adjacent wingtip sails, air flowing on the upper surfaces of the wingtip sails is slowed down, so that a pressure difference is obtained, and the wingtip vortex intensity is reduced accordingly.

Owner:COMAC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com