Low specific speed impeller with function of drag reduction by grooves

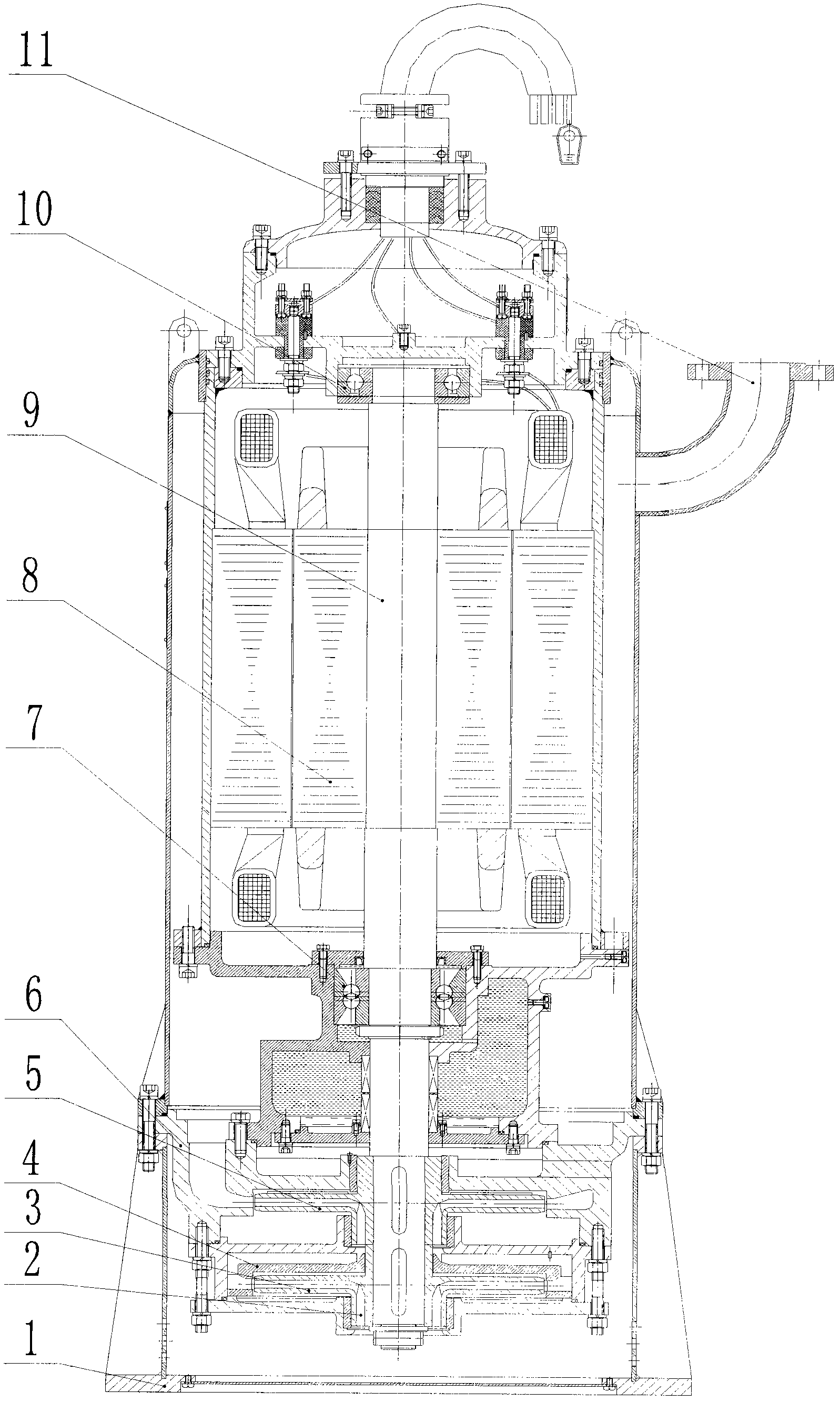

A low-specific-rotation-number, groove-based technology, applied to parts of pumping devices for elastic fluids, non-displacement pumps, machines/engines, etc., can solve low-efficiency and wasteful impeller centrifugal pumps with low specific revolutions Large energy and hydraulic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

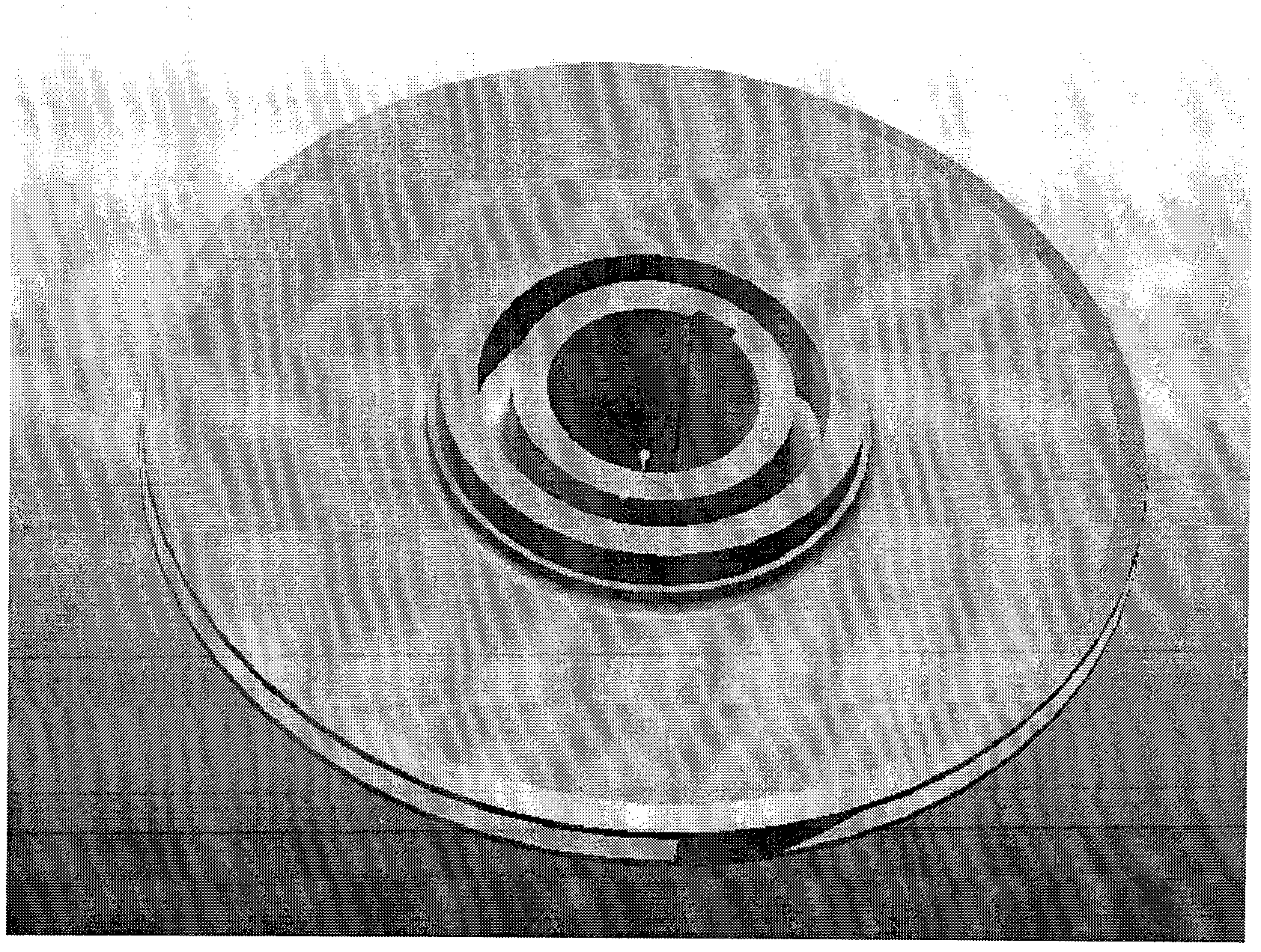

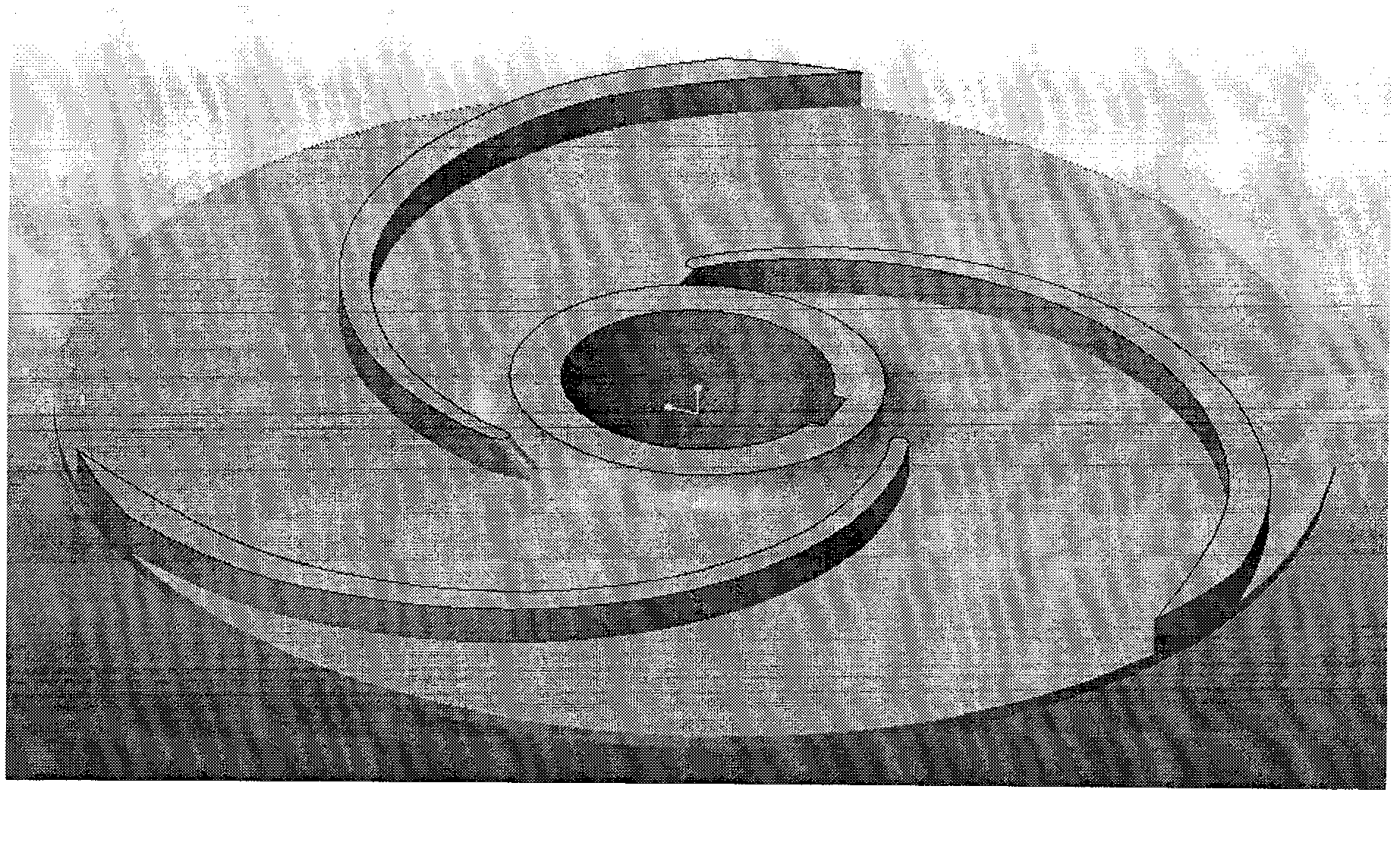

[0014] For the novel impeller of the present invention, the overall structure of the blade and the rear cover is first obtained by casting, and then the working surface and the back of the blade are processed by a CNC milling machine such as the attached Figure 4 In the V-shaped groove shown, the included angle of the groove is 60°, and the height of the groove is 2-4mm. The integral structure of front cover plate and blade and back cover plate is welded together again. Finally, the outer surface of the impeller is finished, and the precision of the mouth ring is guaranteed by lathe processing. Figure 5 keyway shown.

[0015] Through the above method, a low specific speed impeller with a new groove structure is processed. Since the impeller is only different from the traditional low specific speed impeller on the surface of the blade, and the impeller hub and front and rear cover plates have no corresponding changes, so When installing, it is still installed in the same wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com