Volute casing of forward curved multi-blades centrifugal fan

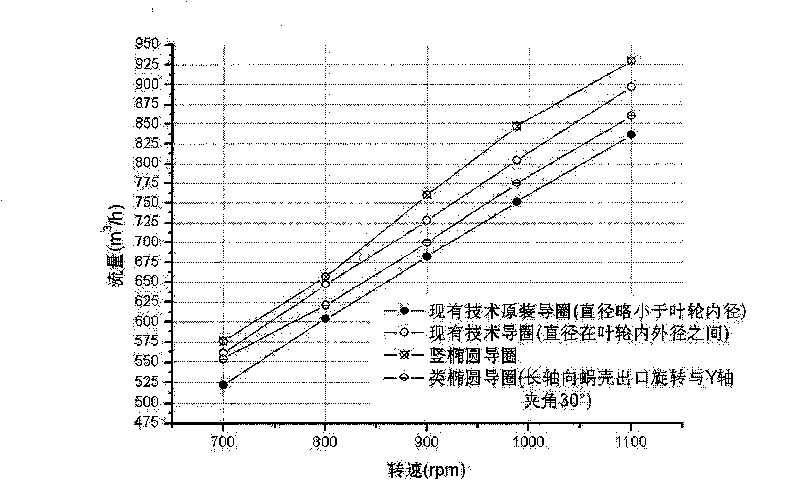

A centrifugal fan and volute technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of uneven circumferential airflow at the outlet of the guide ring, and achieve the effect of improving fan performance and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

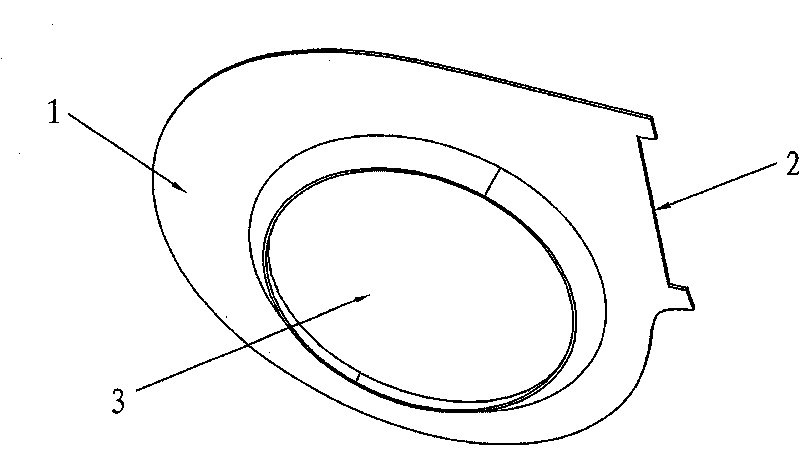

[0021] Such as figure 2 As shown, the volute of a forward multi-blade centrifugal fan includes a volute 1, a guide ring 3 located on the worm plate 2, and an outlet 2 located on the worm plate. The guide ring 3 is oval-like, and the guide ring 3 The center coincides with the center of the impeller.

[0022] An ellipse whose major semiaxis is on the Y axis and whose minor semiaxis is on the X axis is called a vertical ellipse, otherwise it is called a horizontal ellipse;

Embodiment 2

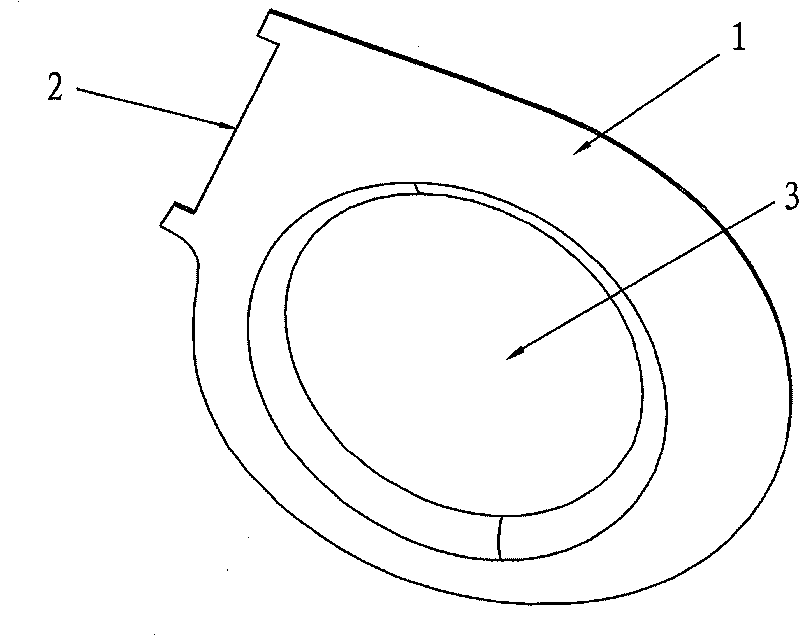

[0024] Such as image 3 As shown, the guide ring 3 is in the shape of a transverse ellipse.

Embodiment 3

[0026] Such as Figure 4 , Figure 5 As shown, a multi-blade centrifugal fan volute includes a worm plate 1, a guide ring 3 located on the worm plate 2, and an outlet 2 located on the worm plate. The centers coincide. The long semi-axis 5 of the guide ring 3 has an included angle θ with the Y axis, one end of the long semi-axis 5 is close to the outlet 2 area on the snail plate 1, and one end of the short semi-axis 4 is close to the volute tongue 6 area of the snail plate 1; Said, the guide ring 3 is in the shape of a vertical ellipse turning counterclockwise at a certain angle.

[0027] The present invention is a volute of a forward multi-wing fan, the semi-major axis 5 of the guide ring 3 is slightly smaller than the outer radius of the impeller, and the semi-major axis 5 of the guide ring 3 has an included angle θ with the Y axis, and the range is 0 °-30°;

[0028] Or the semi-minor axis 4 of the guide ring 3 is slightly smaller than or equal to the inner radius of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com