A diversion structure for ventilation and air supply facilities in open flow flood discharge tunnels

A technology for flood discharge tunnels and facilities, applied in marine engineering, construction, barrage/weir, etc., can solve the problems of small air volume, increased engineering volume, strong noise, etc., and achieve a good working environment, low engineering cost, and noise reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

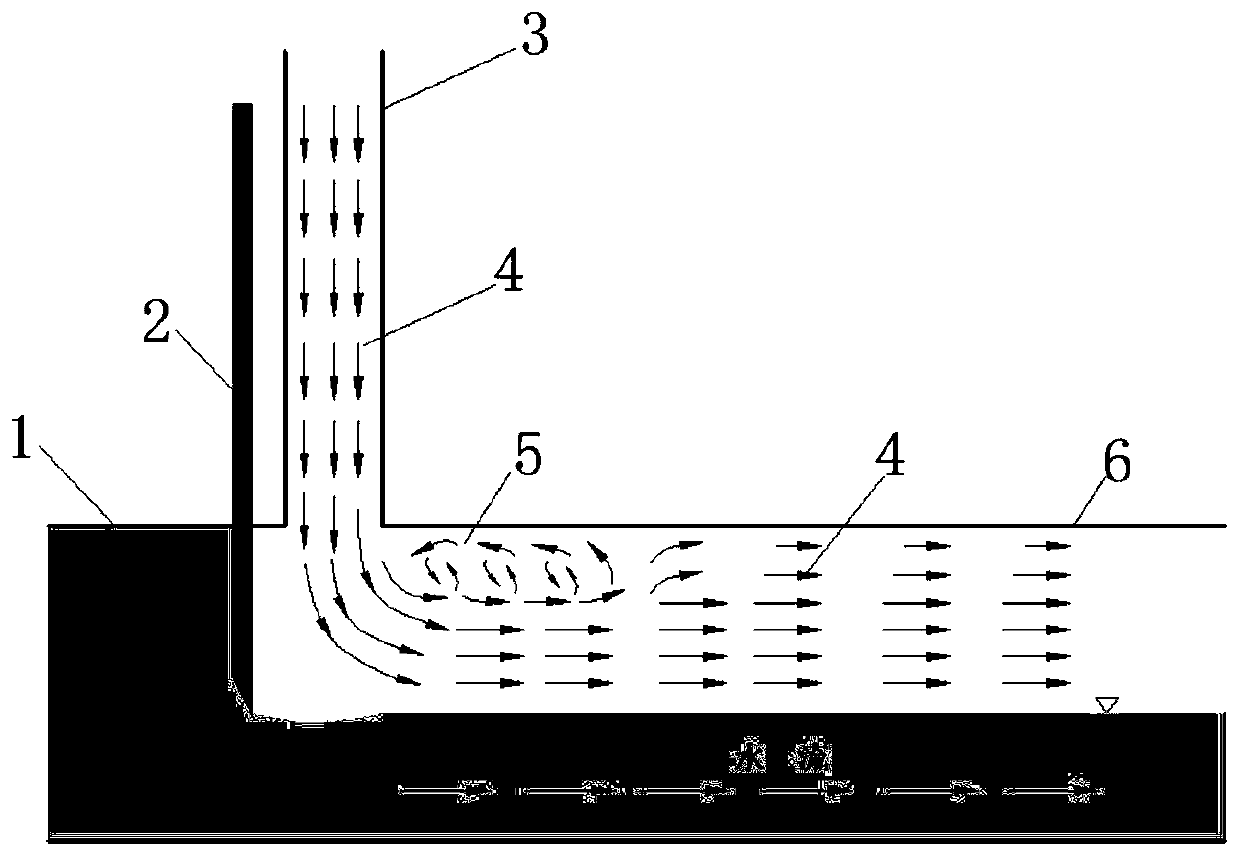

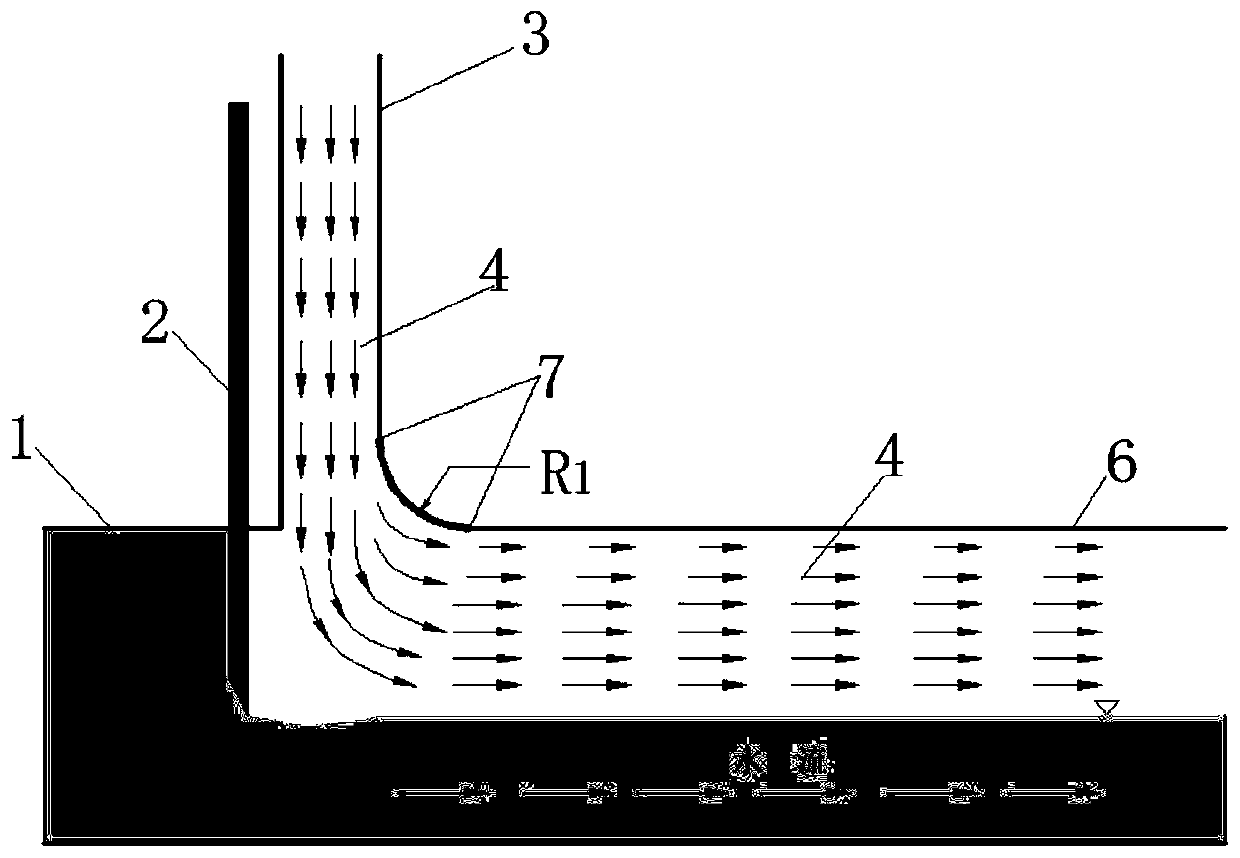

Embodiment 1

[0025] The diversion structure of the ventilation and air supply facilities of the open flow flood discharge tunnel described in this embodiment is constituted as attached image 3 , Figure 5-4shown. The length of open flow flood discharge tunnel 6 is 200 meters, the width is 10 meters, and the flow velocity of the flood discharge is 30m / s. The ventilation and air supply well of ventilation and air supply facility 3 is set at the beginning position of the open flow flood discharge tunnel behind the flood discharge gate 2, and the ventilation and air supply well is vertical. In the open flow flood discharge tunnel, the axis of the ventilation and air supply well is connected with the axis of the open flow flood discharge tunnel. Between the holes, a 1 / 4 arc diversion sill 7 is connected in the direction of the water flow and on both sides, and a right-angle diversion sill is connected in the counterflow direction, and the diversion sill in the direction of the water flow and ...

Embodiment 2

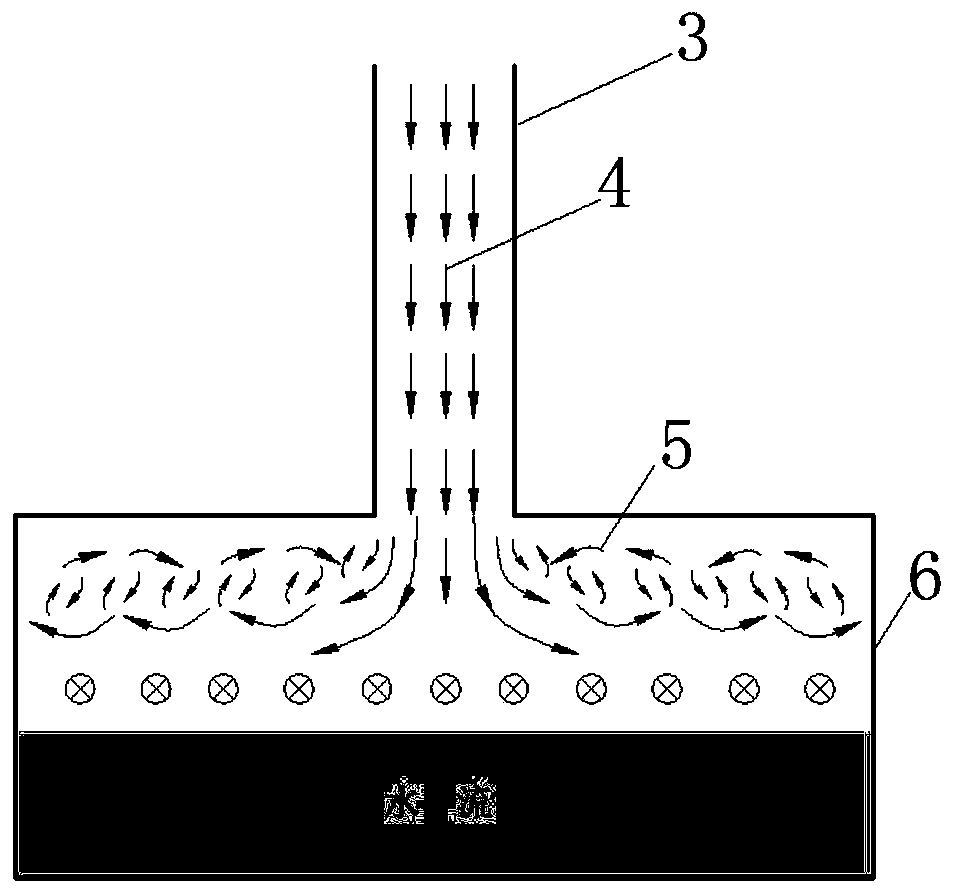

[0027] The diversion structure of the ventilation and air supply facilities of the open flow flood discharge tunnel described in this embodiment is constituted as attached Figure 4 , Figure 5-5 shown. The length of open flow flood discharge tunnel 6 is 200 meters, the width is 10 meters, and the flow velocity of the flood discharge is 30m / s. The ventilation and air supply well of ventilation and air supply facility 3 is set at the beginning position of the open flow flood discharge tunnel behind the flood discharge gate 2, and the ventilation and air supply well is vertical. In the open flow flood discharge tunnel, the axis of the ventilation well is connected with the open flow flood discharge tunnel axis, and its cross-sectional area is a circle with a radius of 2 meters. The ventilation well and the open flow flood discharge tunnel are connected by an arc diversion sill 7. The arc diversion sill is 1 / 4 arc diversion sill in different directions, and the arc radius R of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com