Compressor with two-grade scroll structure

A compressor and scroll technology, which is applied in the field of double-stage scroll compressors, can solve the problems of reducing the exhaust temperature of the compressor, unsatisfactory operating conditions, and reducing the effective refrigerant flow rate, etc., so as to reduce the maximum load and reduce the resistance , liquid spray or full air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

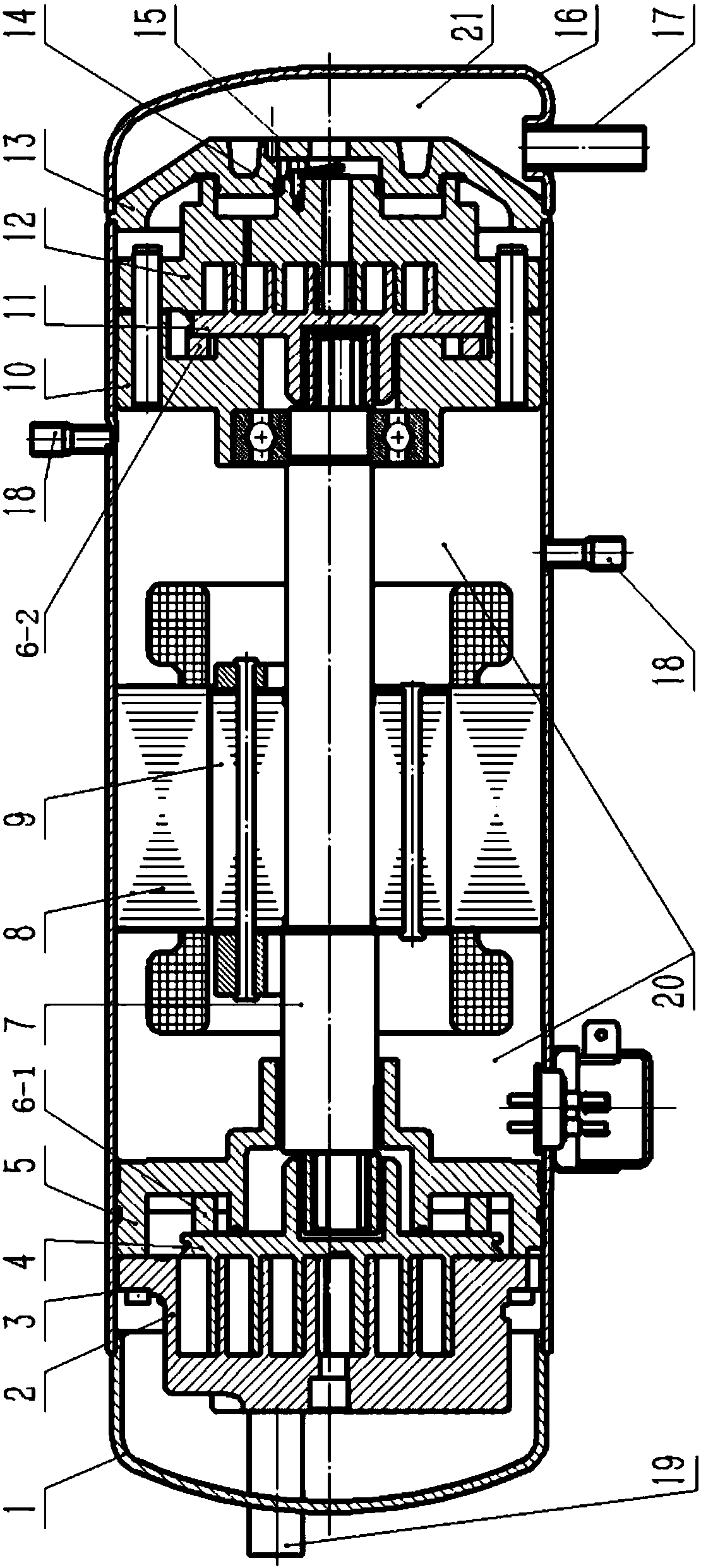

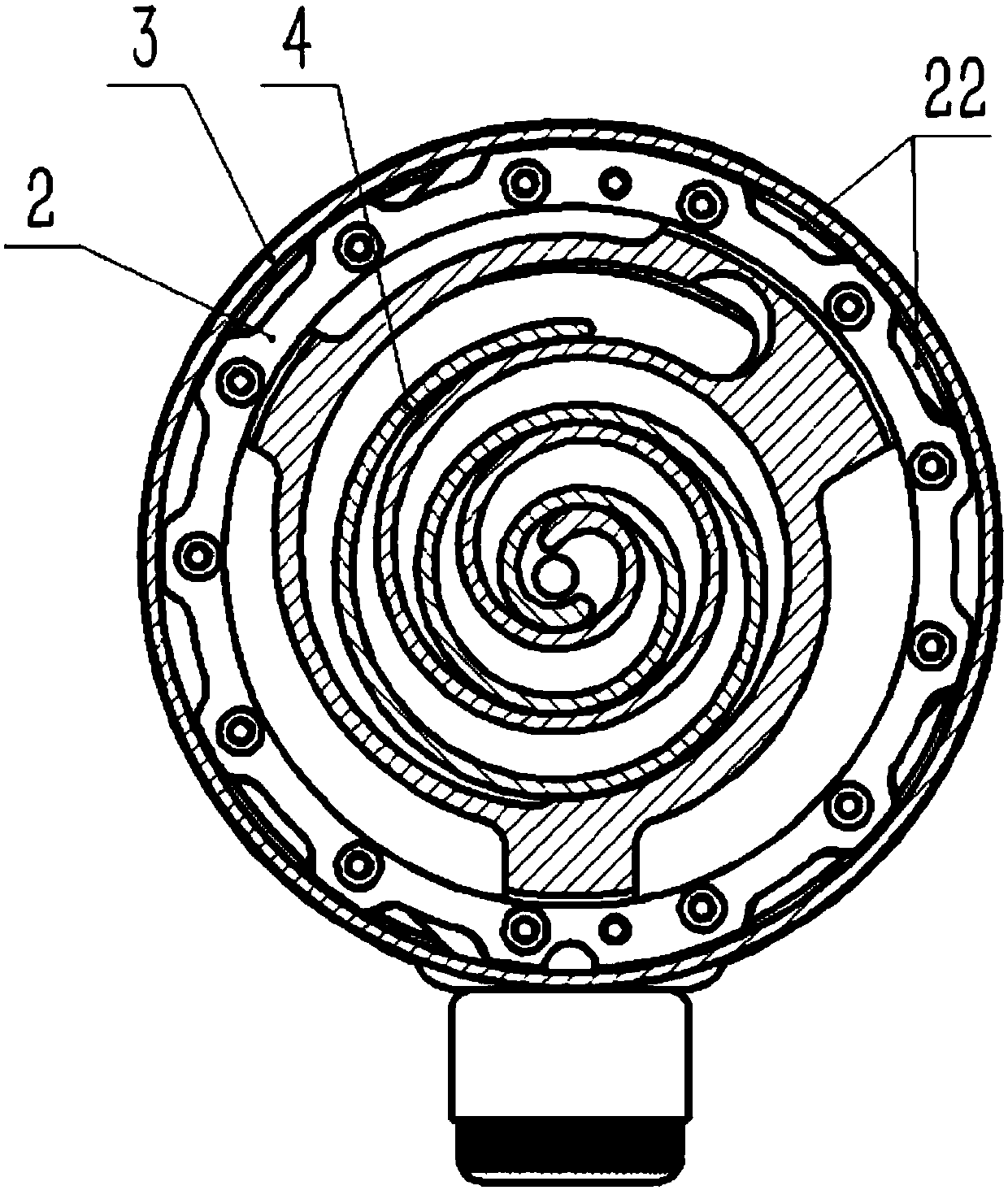

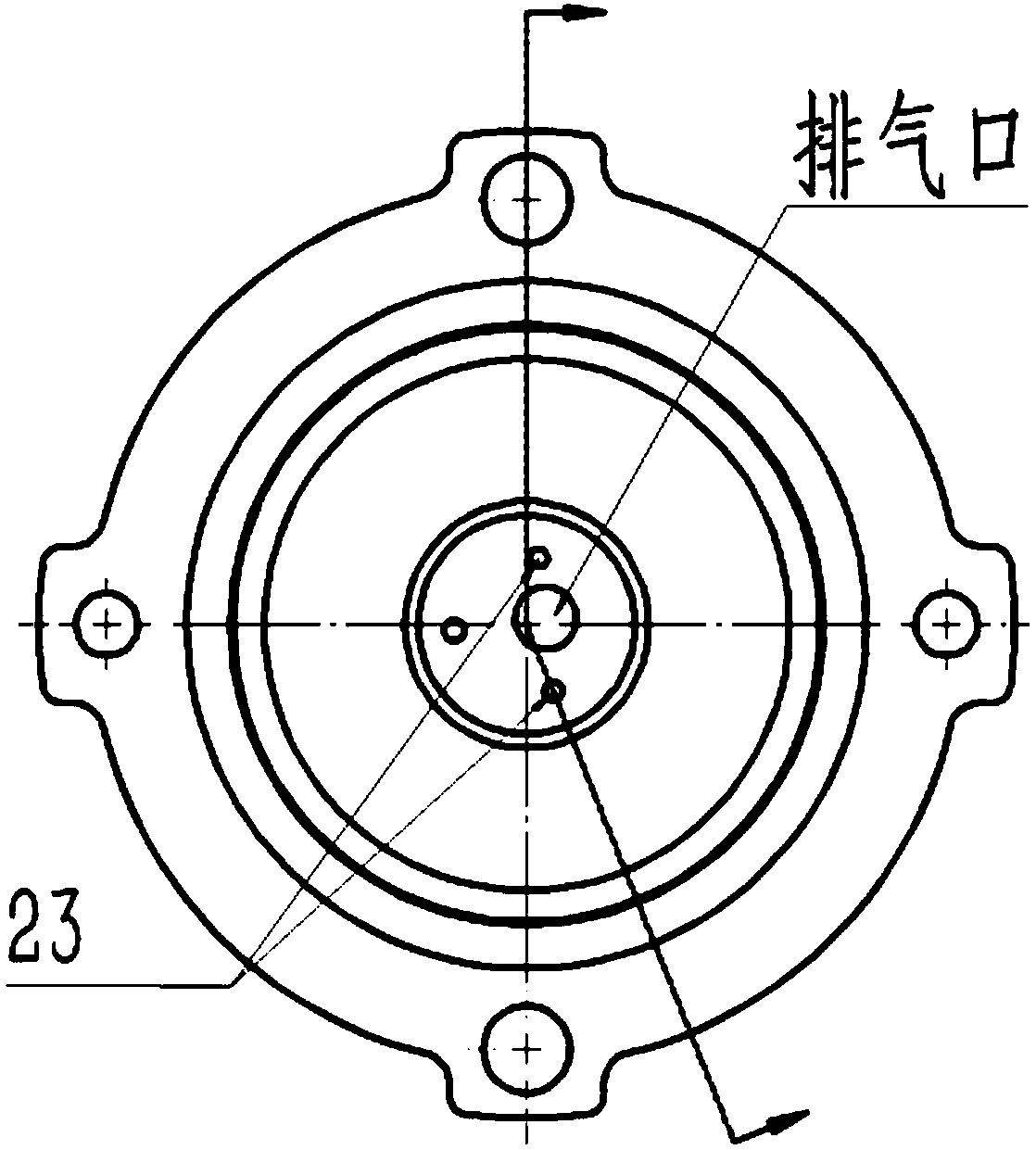

[0027] See attached picture.

[0028] A kind of compressor of two-stage scroll structure, comprises shell 3, and described shell 3 is provided with a horizontal drive crankshaft 7, is characterized in that: one end of described drive crankshaft 7 is equipped with bearing support I5, and described A fixed scroll I2 is installed on the outer side of the bearing support I5, and the end of the bearing support I5 is installed with a movable scroll I4 located between the fixed scroll I2 and the bearing support I5 and cooperating with the fixed scroll I2. An anti-rotation mechanism I6-1 is installed between the spin I4 and the bearing support I5; the other end of the drive crankshaft 7 is installed with a bearing support II10, and the outer side of the bearing support II10 is equipped with a fixed scroll II12, and the bearing support II10 The end of the fixed scroll II11 is installed between the fixed scroll II12 and the bearing support II10 and cooperates with the fixed scroll II12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com