Molten iron desulfurization stirrer

A hot metal desulfurization and agitator technology, which is applied to mixers with rotating agitation devices, chemical instruments and methods, mixers, etc., can solve problems such as mechanical damage to slag removal, difficult processing and manufacturing, and wear on the bottom of the agitator. Reduce the retention effect and sticky slag speed, improve the stirring entrainment strength, and increase the effect of the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

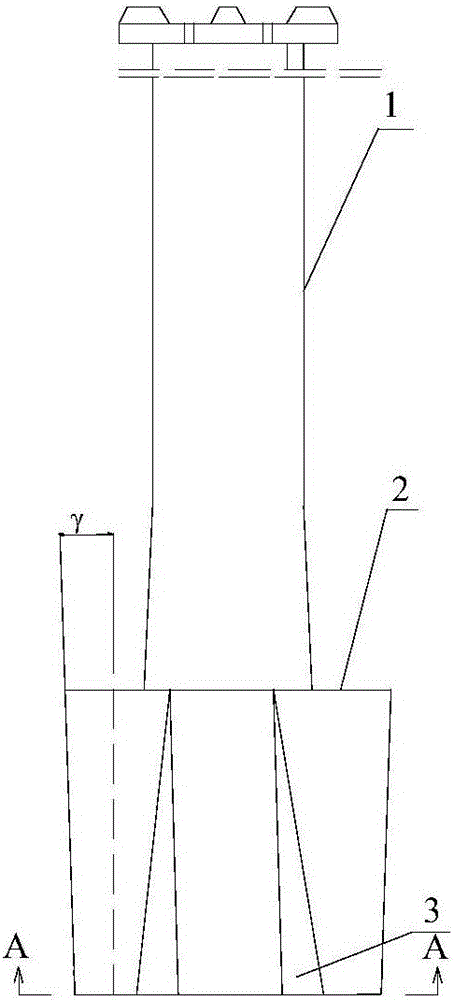

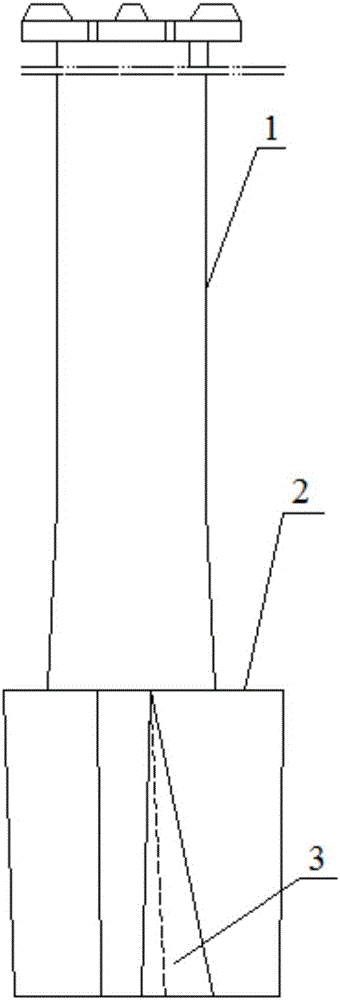

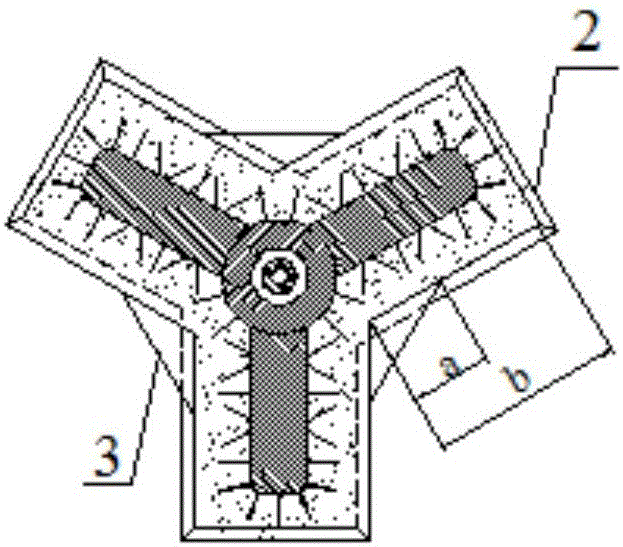

[0032] There are three stirring blades 2, which are evenly distributed in the circumferential direction around the rotating shaft 1. The outer surface of the stirring blade 2 is a slope that inclines radially outward at an angle γ from bottom to top, and γ is 2°. The water surface of the stirring blade 2 is clockwise. The direction is tilted forward by angle α from bottom to top, and the back iron water surface is a slope that tilts forward by angle β from bottom to top in a clockwise direction, and α is 6°, and β is 8°. The length of the stirring blade 2 is 50mm longer than that of the conventional stirring blade 2 . The guide body 3 is a triangular cone-shaped refractory material structure, and is cast together with the stirring blade 2; the common side length of the triangular bottom surface 8 of the guide body 3 and the stirring blade 2 is a, and the length of the stirring blade 2 is b, and a=0.4b.

Embodiment 2

[0034] There are four stirring blades 2, which are evenly distributed in the circumferential direction around the rotating shaft 1. The outer surface of the stirring blade 2 is a slope that inclines radially outward at an angle γ from bottom to top, and γ is 2°. The water surface of the stirring blade 2 is clockwise The direction is tilted forward by an angle α from bottom to top, and the back iron water surface is a slope that tilts forward by an angle β from bottom to top in a clockwise direction, and α is 8°, and β is 12°. The length of the stirring blade 2 is 50mm longer than that of the conventional stirring blade 2 . The guide body 3 is a slope-shaped refractory structure with a concave curved surface, and is cast together with the stirring blade 2; the common side length of the triangular bottom surface of the guide body 3 and the stirring blade 2 is a, and the length of the stirring blade 2 is b, and a=0.3b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com