Wingtip device for aircraft wing

A wing and wing tip technology, which is applied to the wing tip device field of the main wing of an aircraft, can solve the problem that the shape design of the sail does not consider the sweep angle and the skimming angle, and does not consider the fusion of the wing tip sail and the wing. The general drag reduction effect of tip sails can achieve the effect of increasing lift, reducing drag, and weakening shock wave intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

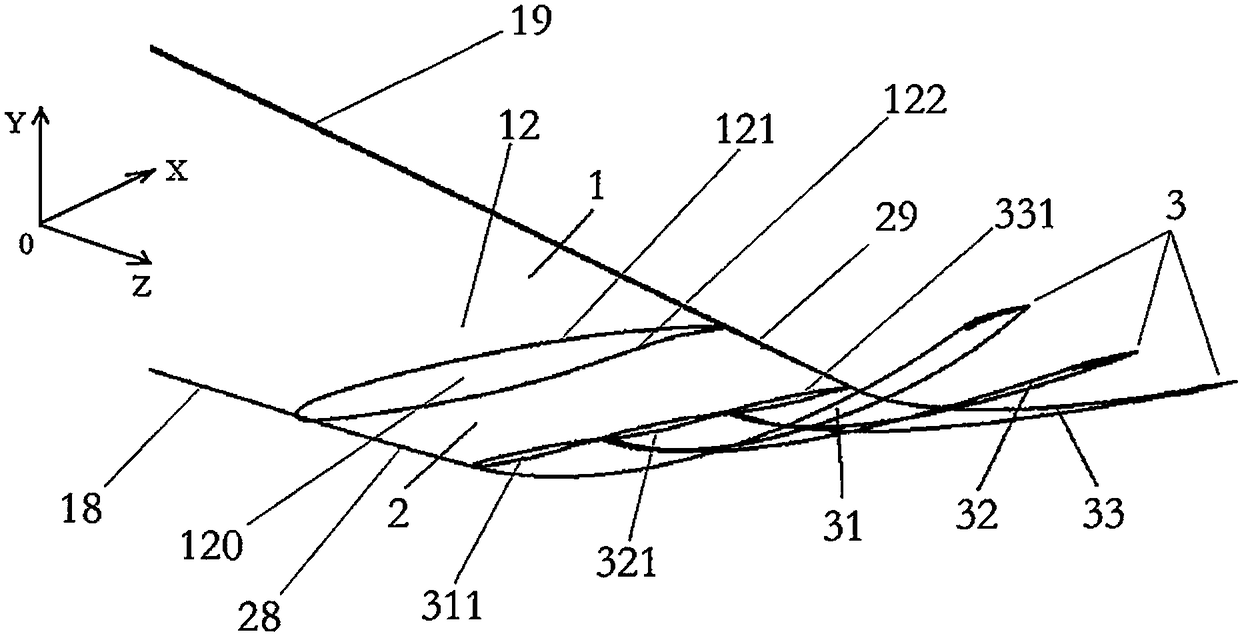

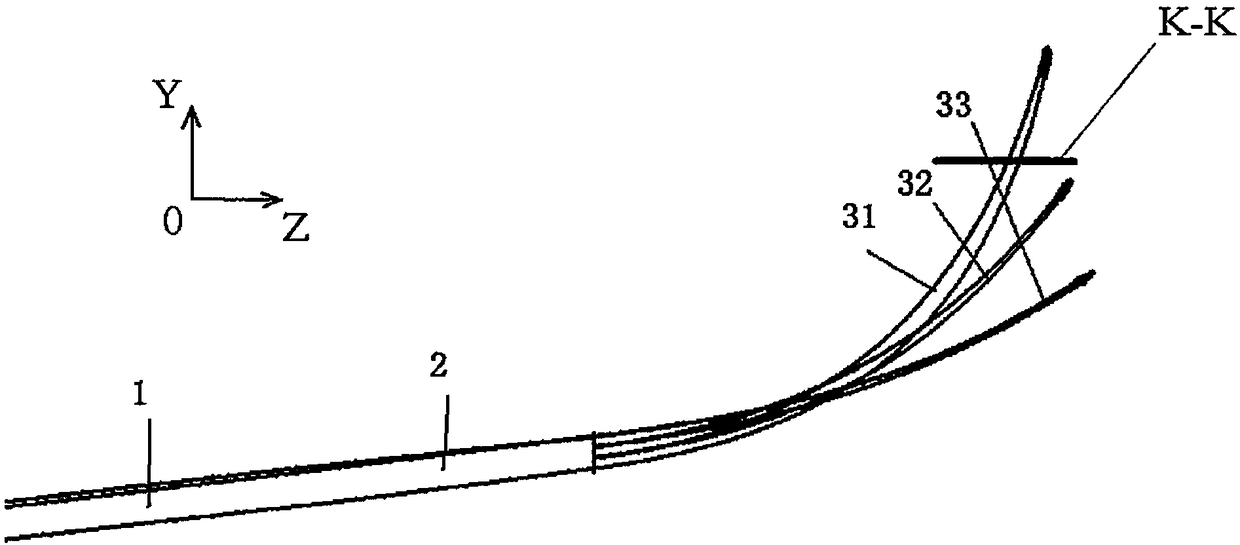

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. For the convenience of the discussion, "up", "down", "left", and "right" are used to indicate the directions in each schematic diagram, which is conducive to the development of the discussion. According to the characteristics of the present invention, the specific implementation method is in figure 2 The XYZ coordinate system is shown in , and the XOY plane view, YOZ plane view, and ZOX plane view are used in some of the subsequent drawings. When reading these drawings, you can combine figure 2 The three-dimensional diagram in is understood.

[0042] Such as figure 2 Shown is the preferred embodiment of the wingtip device of the aircraft wing of the present invention, in particular, the preferred embodiment of the wingtip device of the main wing of the aircraft. Nevertheless, those skilled in the art can understand that the technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com