Vertical centrifugal pump unit with noise reduction function and low vibration level

A centrifugal pump and vertical technology, which is applied in the field of noise reduction and low vibration level vertical centrifugal pumps, can solve the problems of limited vibration and noise of loaded centrifugal pumps, achieve good cooling effect, improve flow state, and reduce vibration sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

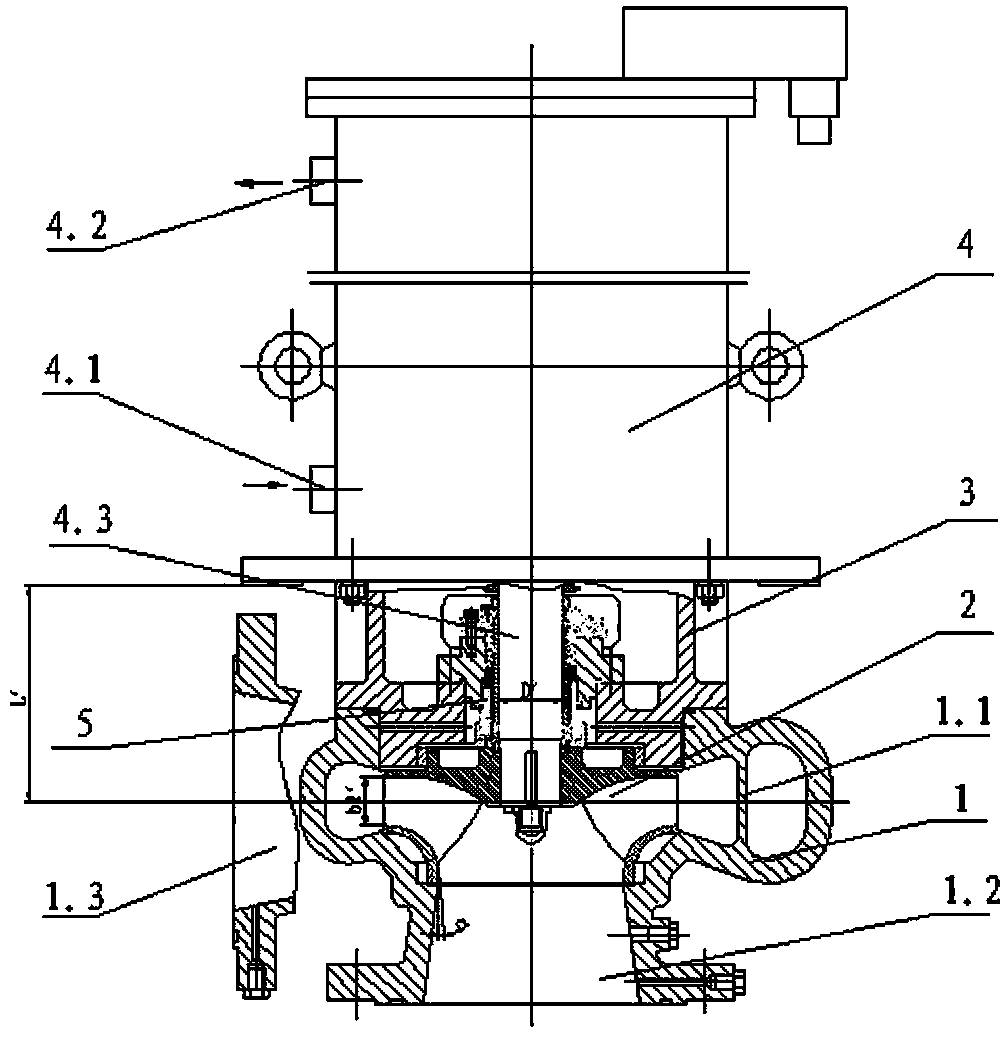

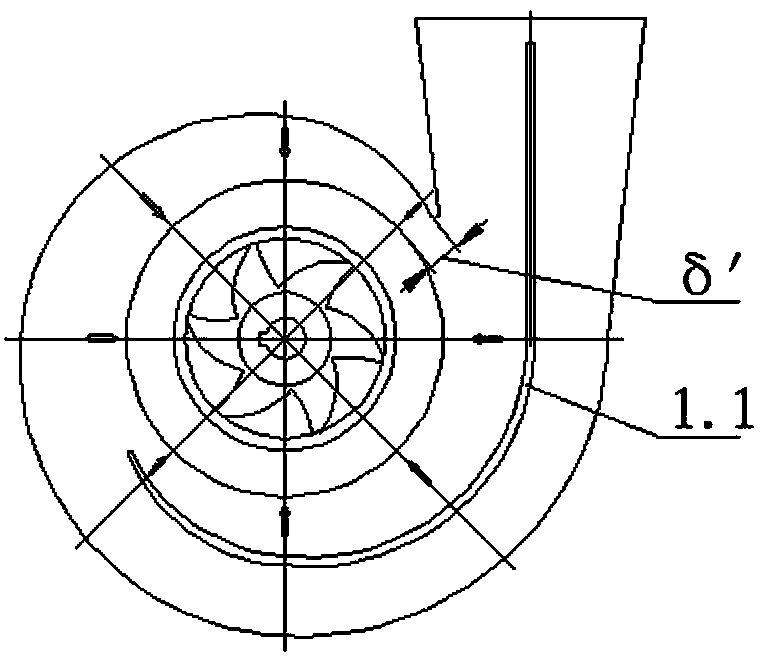

[0022] figure 1 The embodiment shown is a Q=300m 3 / h, H=30m noise-reducing low-vibration level vertical centrifugal pump set, this embodiment is matched with a manned deep submersible device, which includes a pump body 1, an impeller 2, a bracket 3, a motor 4, and a shaft seal 5. The pump body 1 is a single-stage single-suction vertical structure, the pump inlet 1.2 is located at the bottom and faces downward, and the pump outlet 1.3 on the side is perpendicular to the pump inlet 1.2. The flow channel in the inner cavity of the pump body 1 is placed horizontally, and the flow channel is separated by the partition plate 1.1 as follows: figure 1 or figure 2 In the shown inner and outer double volute structure, the impeller 2 is placed in the inner volute. In order to reduce the pressure pulse amplitude in the pump, one of the techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com