Boundary layer suction type propeller adopting large and small two-stage blades

A propeller and boundary layer technology, applied in the direction of propeller, drag reduction, transportation and packaging, etc., can solve the problems of increased blade root vortex strength, increased power consumption, intake distortion, etc., to suppress root airflow separation, reduce root The effect of swirl intensity and tolerance of intake distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

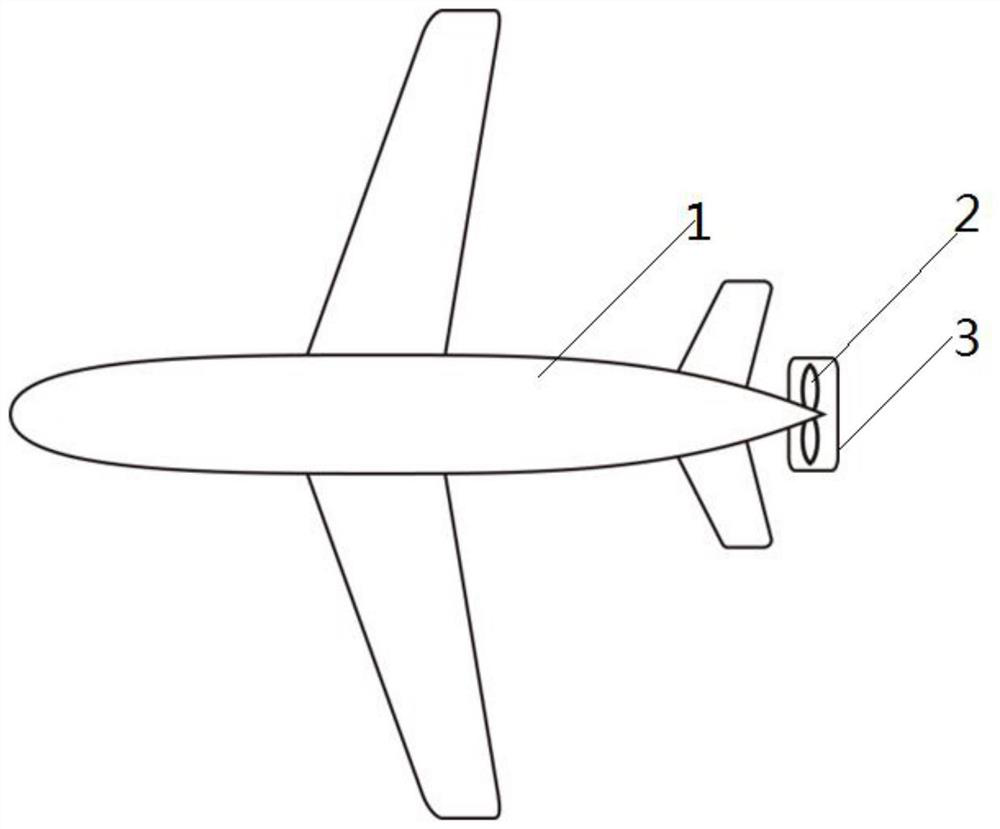

[0055] A boundary layer suction propeller using two-stage blades of different sizes is installed on an aircraft, the aircraft is a C919 aircraft with a wingspan of 35 meters, a maximum take-off gross weight of 73 tons, and a cruising speed of Mach 0.7 to 0.84;

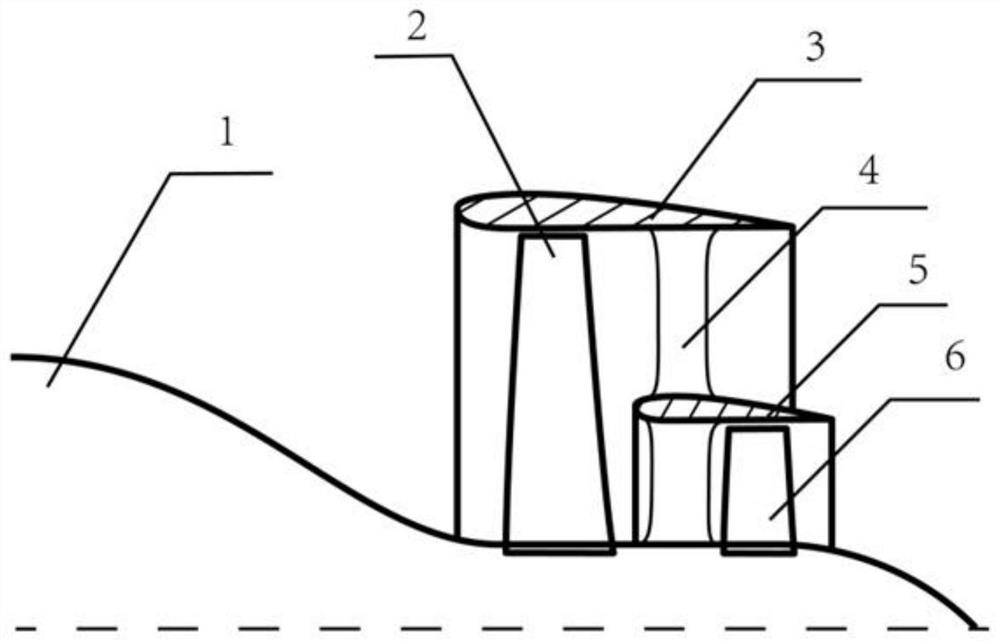

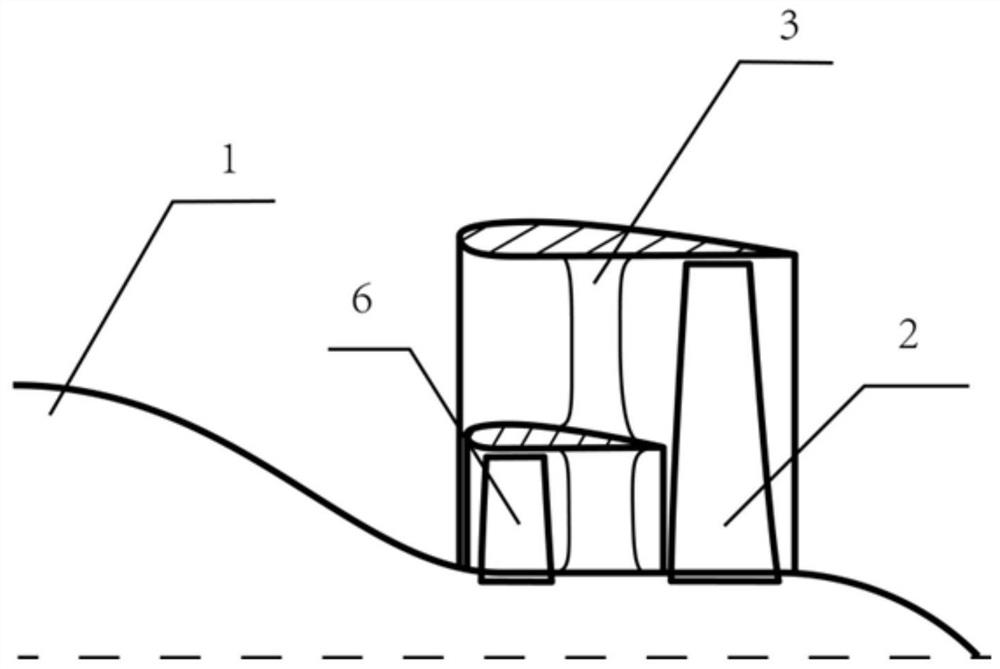

[0056] In the boundary layer suction propeller using two stages of large and small blades, the distance between the large rotor and the small rotor is 0.9m,

[0057] The diameter of the large rotor is 1.8m, and the diameter of the small rotor is 0.6m;

[0058] The design speed of the large rotor is 5000RPM, and the design speed of the small rotor is 8000RPM;

[0059] The vehicle has an economical fuel consumption rate of 2.7 tons per hour with a payload of 70 tons and a cruise speed of Mach 0.78.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com