Continuous casting crystallizer copper plate design method for improving electromagnetic stirring efficiency

A continuous casting mold and electromagnetic stirring technology, which is applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems that the alternating magnetic field cannot completely penetrate the copper plate, the electromagnetic stirring efficiency is low, and the magnetic field shielding effect is large. Achieve the effect of reducing shielding effect, reducing solidification defects and improving steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0035] The invention provides a method for designing a copper plate of a continuous casting crystallizer to improve the efficiency of electromagnetic stirring.

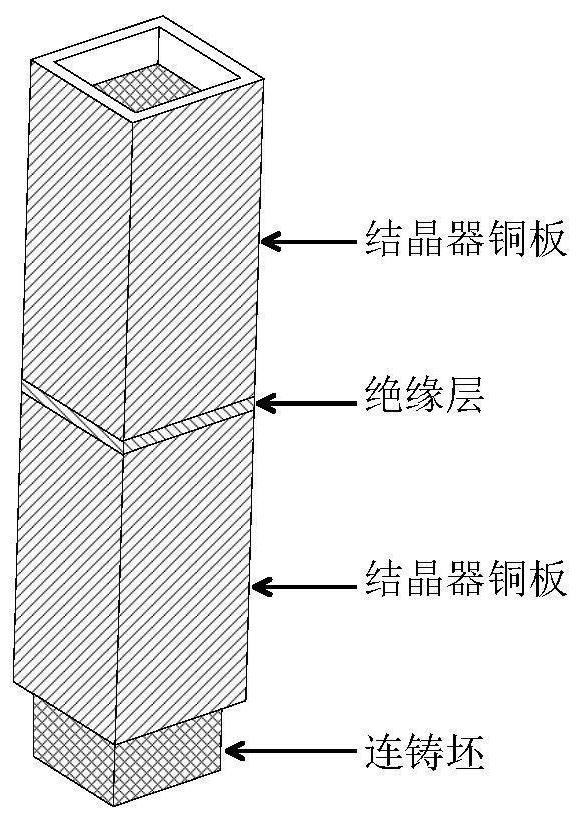

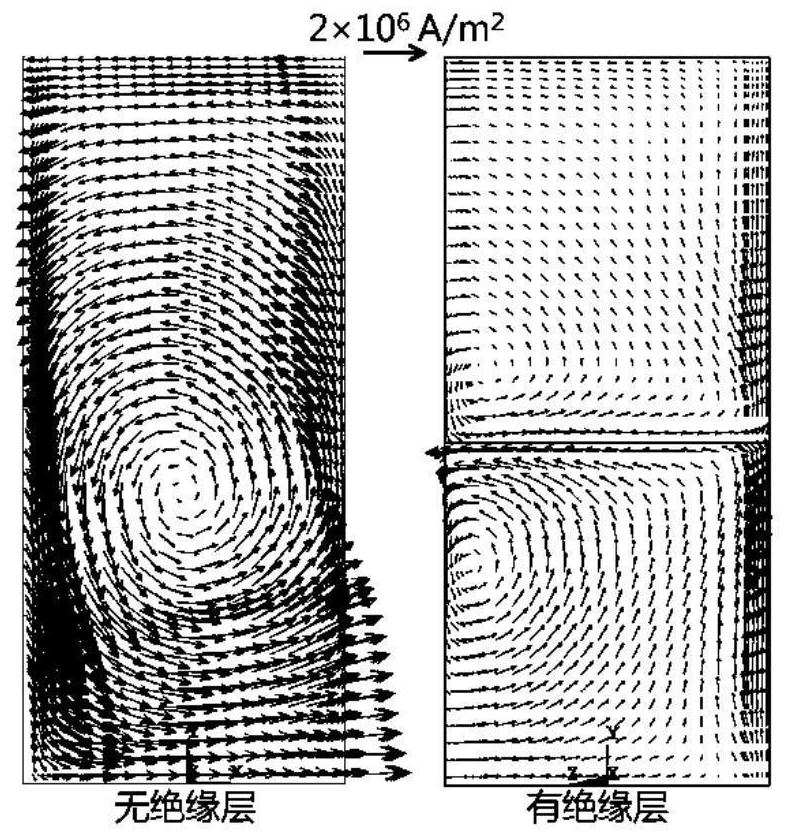

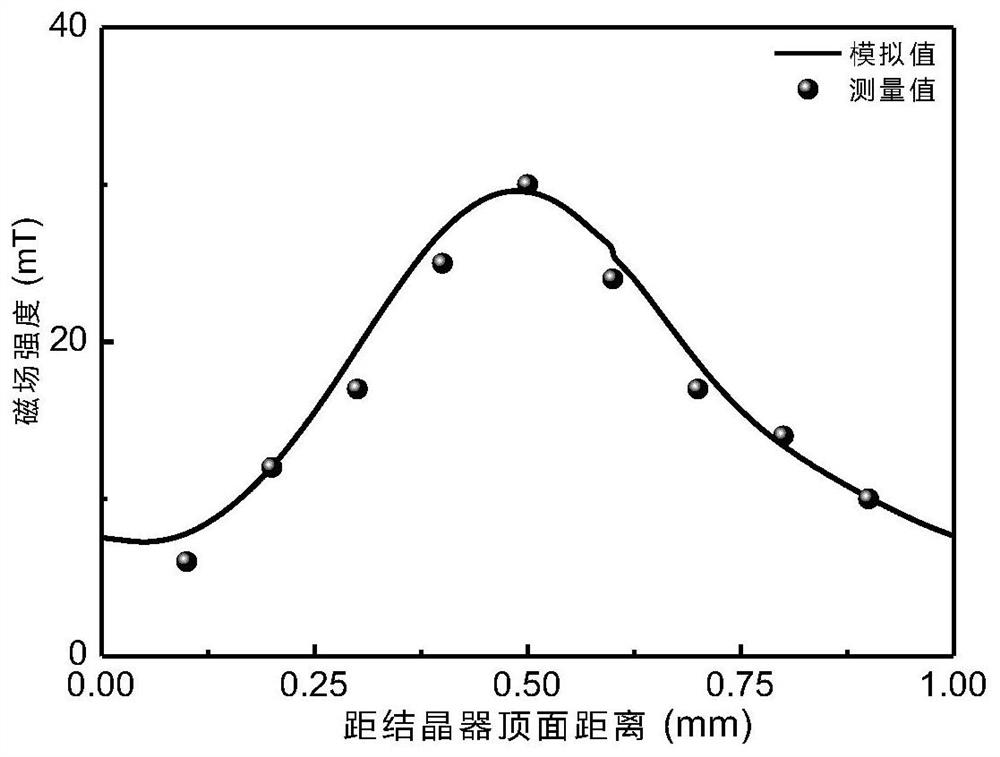

[0036] Such as figure 1 As shown, the method provides an insulating layer in the copper plate of the traditional continuous casting mold. Due to the existence of the insulating layer, the eddy current intensity of the copper plate under the condition of alternating magnetic field is significantly reduced, as shown in figure 2 As shown, thereby improving the penetrating ability of the alternating magnetic field, increasing the efficiency of electromagnetic stirring, reducing power consumption, improving solidification defects of continuous casting slabs, and improving steel quality.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com