Method and composition for realizing mercapto-alkyne deep photopolymerization

A technology of photopolymerization and composition, which is applied in the field of photopolymerization materials, can solve problems not involved in the photopolymerization of mercapto-yne systems, etc., and achieve the effect of improving the depth of photopolymerization, reducing the shielding effect, and improving the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

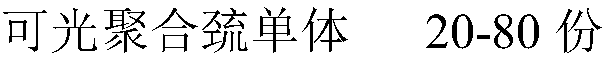

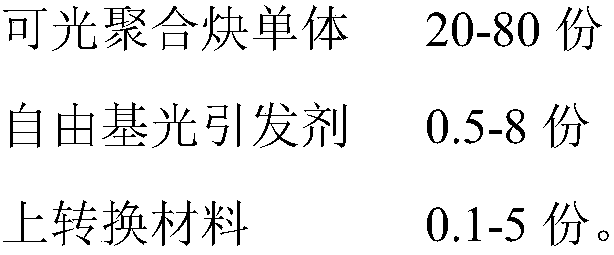

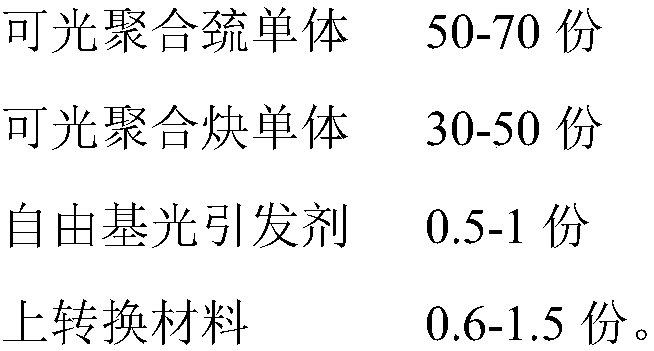

[0029] A composition for realizing deep layer photopolymerization of mercapto-yne, the components contained in the composition and the parts by mass of each component are:

[0030]

[0031] Mix the above composition evenly and add it into the test tube, place it vertically and use the emission wavelength 980nm, energy density 12mW / cm 2 The light source was irradiated from top to bottom on the top of the test tube, and solidified after 3 minutes to obtain a 1.92 cm column, and the triple bond conversion rate at the bottom was 40%.

Embodiment 2

[0033] A composition for realizing deep photopolymerization of mercapto-yne, the components contained in the composition and the mass parts of each component are the same as those in Example 1, the difference lies in changing the up-conversion material NaYF 4 The content is 0.9 parts, the length of the column obtained under the same light conditions is 2.35 cm, and the conversion rate of the triple bond at the bottom is 45%.

Embodiment 3

[0035] A composition for realizing deep photopolymerization of mercapto-yne, the components contained in the composition and the mass parts of each component are the same as those in Example 1, the difference lies in changing the up-conversion material NaYF 4 The content is 1.2 parts, the emission wavelength is 980nm, and the energy density is 20.3mW / cm 2 The light source is irradiated from top to bottom on the top of the test tube. After 3 minutes of curing, the length of the column reaches 4.6 cm, and the conversion rate of the triple bond at the bottom is 42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com