Electromagnet bearing

A technology of electromagnetic bearings and electromagnetic coils, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of consumption, fuel consumption, large startup idle power, etc., and achieve the effects of improving work efficiency, saving energy, and increasing centripetal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

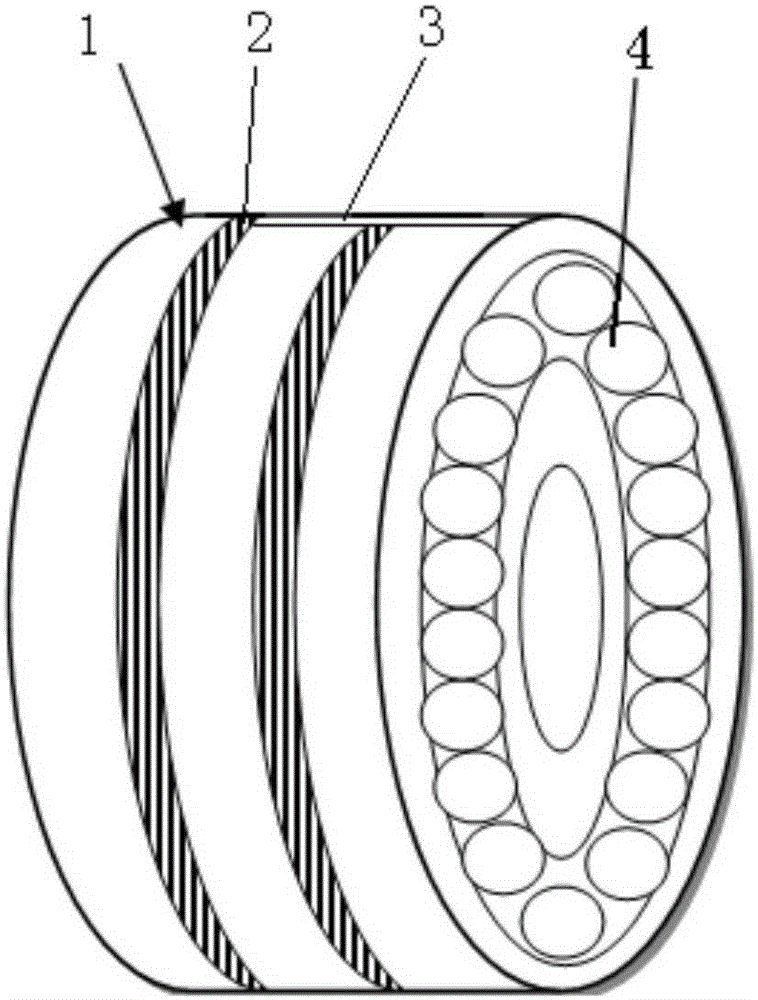

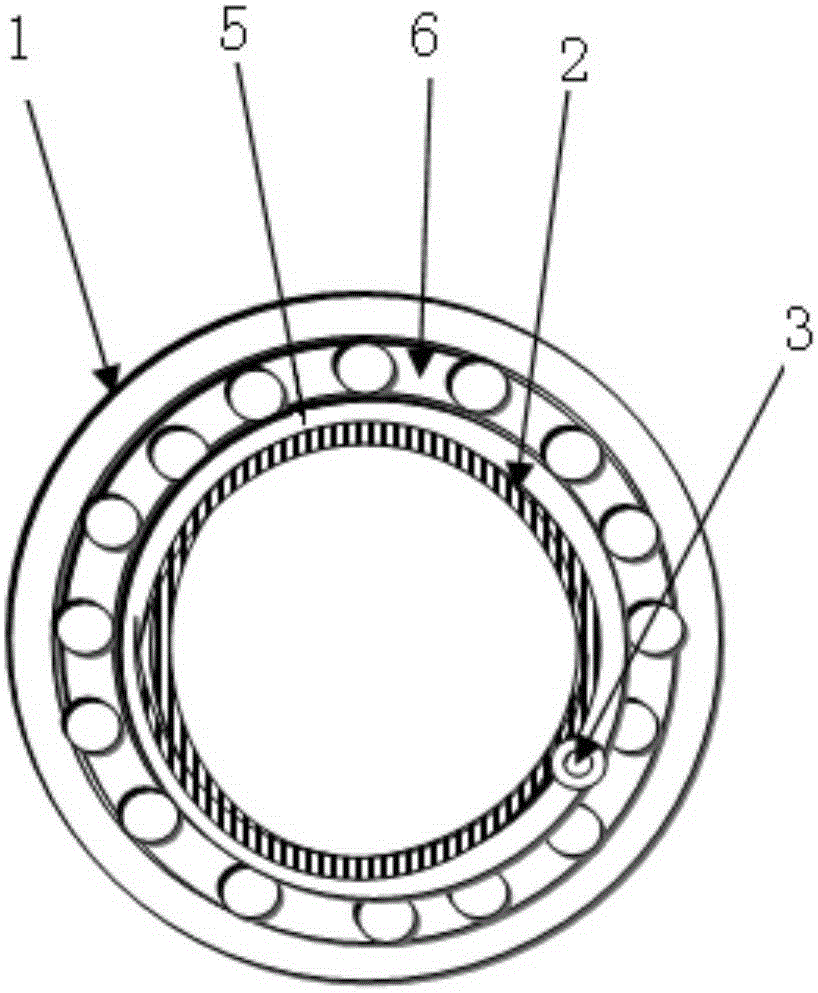

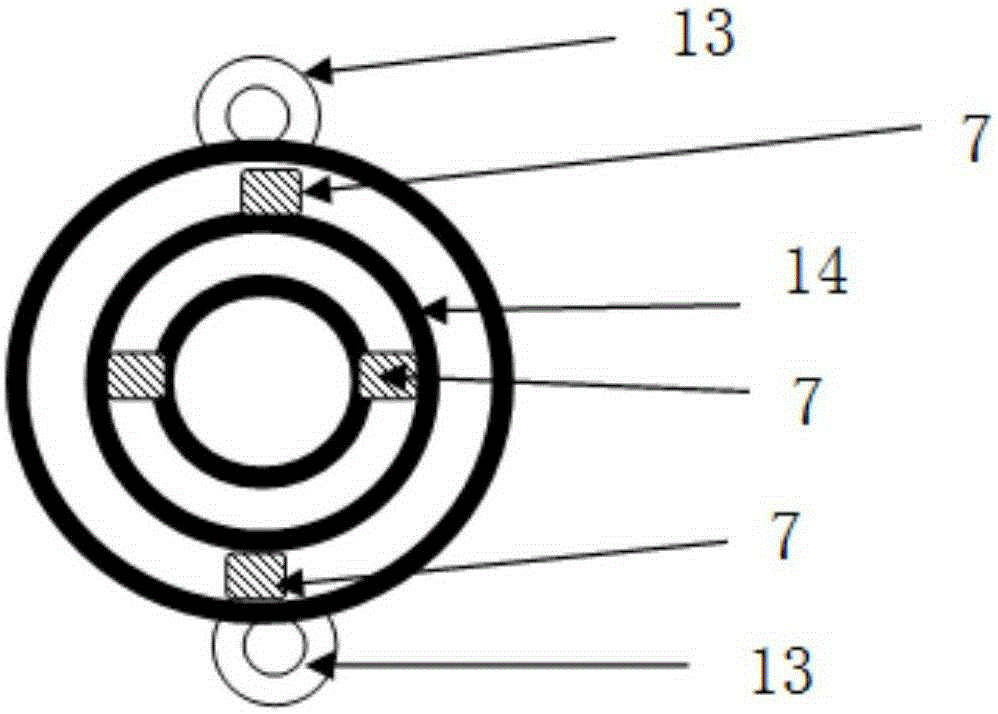

[0016] refer to figure 1 As shown in -5, the present invention provides an electromagnetic bearing, which includes an outer casing 1, an electromagnetic coil 2, a wire groove 3, a supporting roller 4 and an inner sleeve 5. The inner sleeve 5 is provided on the inner side of the outer sleeve 1, and the outer sleeve 1 and the inner sleeve A supporting roller fixing frame net 6 is installed between the cover 5, and supporting rollers 4 are installed on the supporting roller fixing frame net 6, and a wire groove 3 is also provided on the outer cover, and the outer cover 1 and the inner cover 5 are provided with The electromagnetic coil 2, the jacket 1 and the inner jacket 5 are all provided with a fixed assembly 13 and a carbon brush 7, the carbon brush 7 includes a positive electrode carbon brush and a negative electrode carbon brush, the positive electrode carbon brush is fixed on the outer jacket 1 through the fixing assembly 13, and the negative electrode carbon brush The fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com