Multipoint Contact Spur Gear Meshing Pair Based on Conjugate Curves

A multi-point contact, cylindrical gear technology, applied in the direction of gear transmission, belt/chain/gear, components with teeth, etc., can solve the problems of low tooth surface load capacity, large tooth surface sliding rate, tooth surface wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

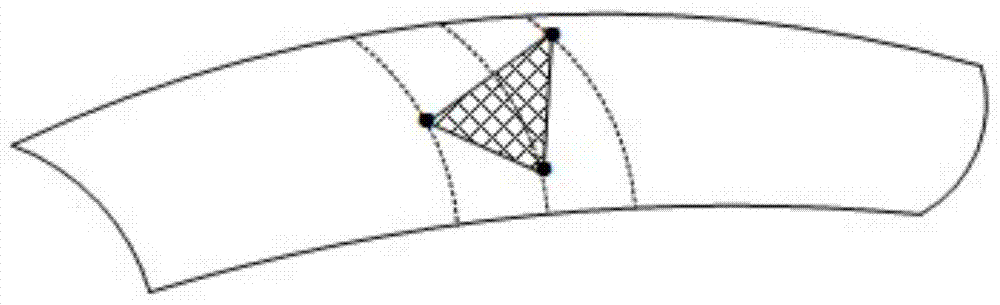

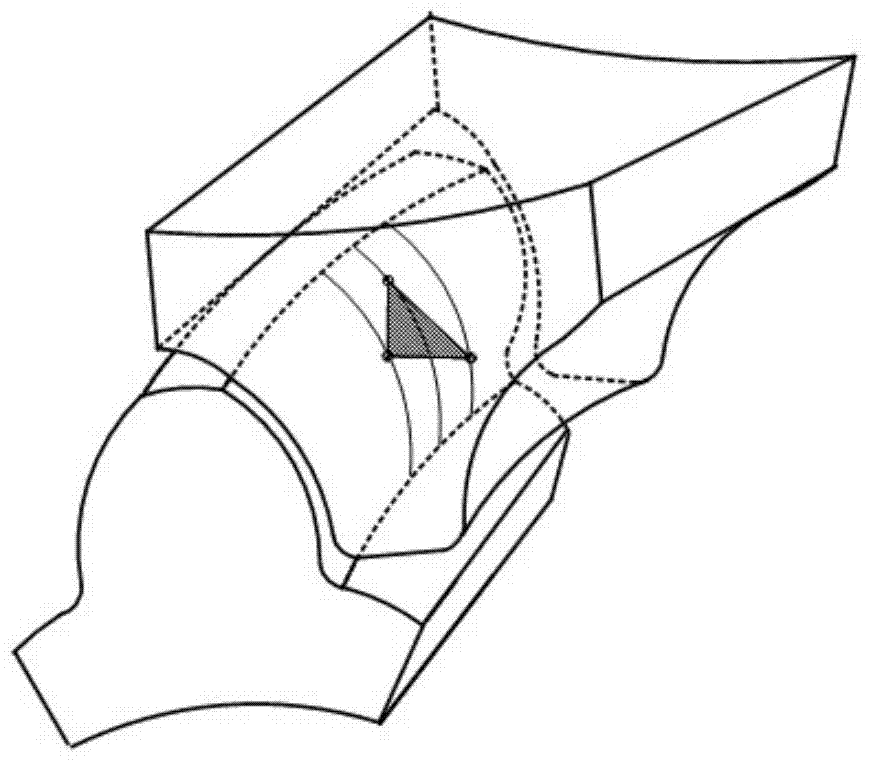

[0098] Such as figure 1 , figure 2 , image 3 In the shown embodiment, the three-segment tooth profile curves are selected in the form of arc curves in the local different sections of the tooth surface, and the optimum point contact pressure angle is determined to realize the general distribution of three-point contact in different sections. Such as figure 1 , 2 As shown, the convex and concave tubular meshing tooth surfaces constructed based on the conjugate curve meshing theory form a paired meshing pair, and the meshing pair moves along the contact point track in the axial direction, and the two are in general three-point contact in the local different sections of the tooth surface;

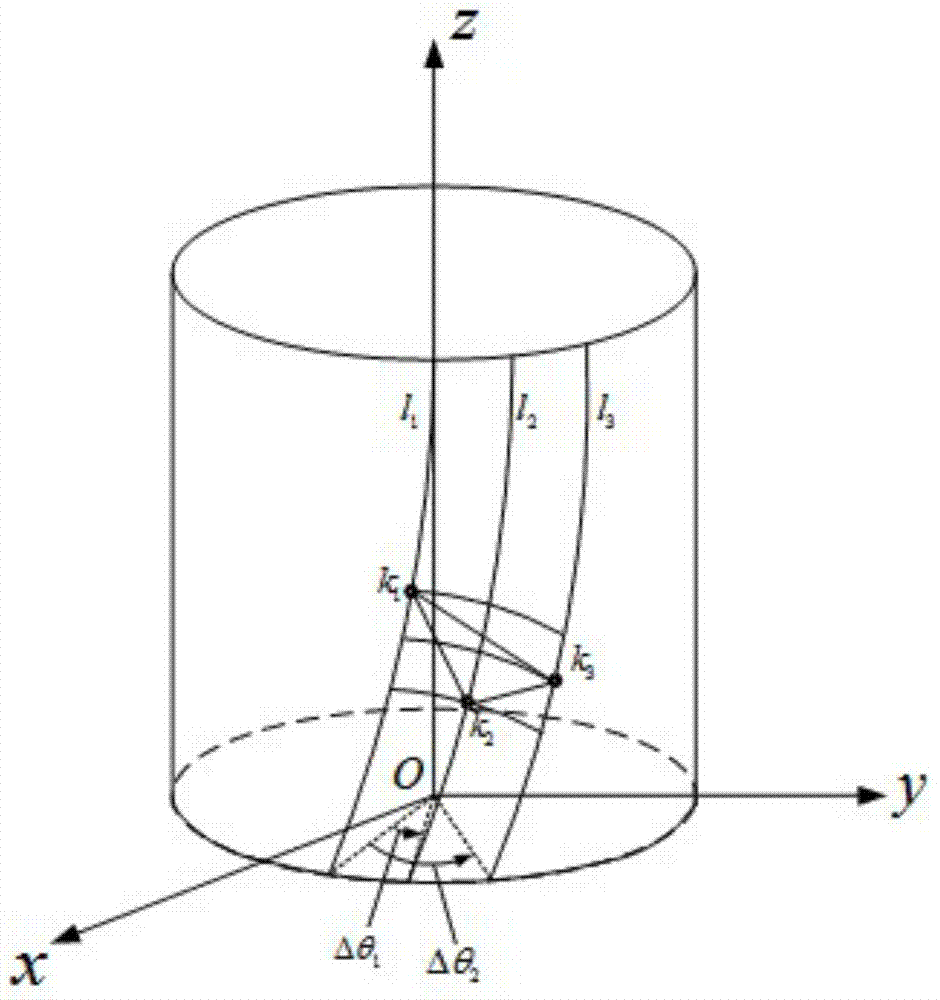

[0099] The cylindrical helix is selected as the conjugate contact curve of the tooth surface. Such as image 3 As shown, in the space coordinate system l 1 , l 2 and l 3 are three helical curves on the cylindrical surface, satisfying the curve l 2 relative curve l 1 Rotation angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com