Sealing ring and mechanical sealing device with same

A sealing ring and sealing end technology, which is applied in mechanical equipment, engine sealing, engine components, etc., can solve problems such as difficult to process, impossible to process directly, and poor processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

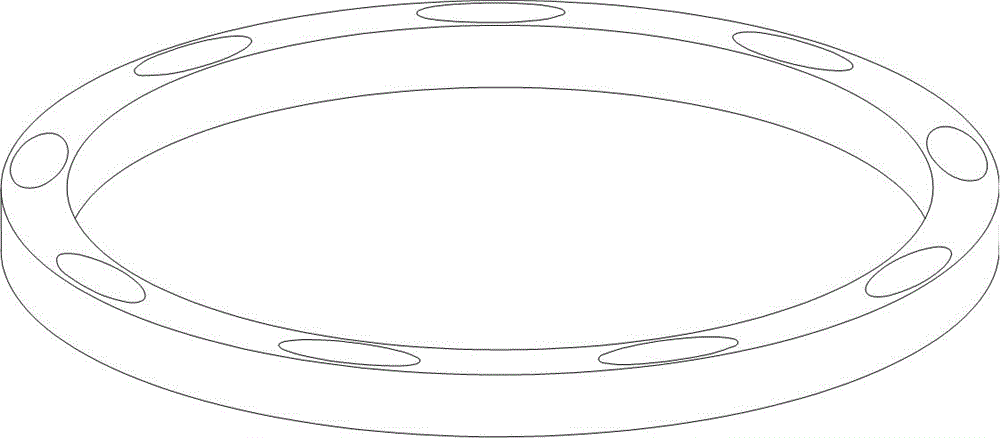

[0094] Example 1: Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 .

[0095] A sealing ring has a flat sealing end surface, and a shallow groove is arranged on the sealing end surface, the bottom surface of the shallow groove is a curved surface, and the bottom surface of the shallow groove is inclined by a sealing end surface with a diameter of 175 mm and is flat The circle with an angle of 0.027 radians is a curved surface obtained after elastic recovery of the smooth continuous curved surface formed when the elastically deformed sealing ring that has deformed the sealing end surface into a non-planar surface moves according to the law of motion. The elastic deformation is the elastic deformation that the inner periphery of the sealing end surface of the sealing ring is 57 microns higher than the outer periphery after a force load uniformly distributed along the circumferential direction is applied to the sealing ring. The said movement rule is...

Embodiment 2

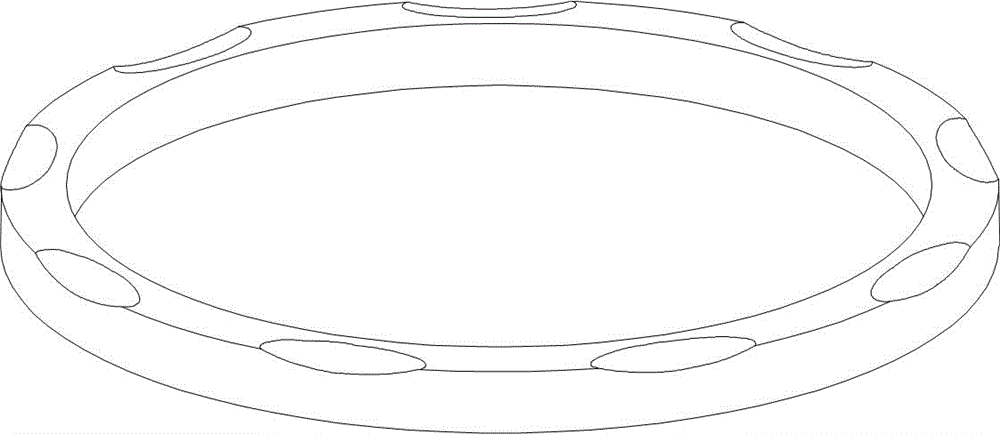

[0097] Example 2: Please refer to Figure 6 , Figure 7 , Figure 8 and Figure 9 .

[0098] A sealing ring has a flat sealing end surface, and a shallow groove is arranged on the sealing end surface, the bottom surface of the shallow groove is a curved surface, and the bottom surface of the shallow groove is inclined by a sealing end surface with a diameter of 175 mm and is flat The circle with an angle of 0.001 radians is a curved surface obtained after elastic recovery of the smooth continuous curved surface formed when the elastically deformed sealing ring that has deformed the sealing end surface into a non-planar surface moves according to the law of motion. The elastic deformation is the elastic deformation that the inner periphery of the sealing end surface of the sealing ring is 24 microns higher than the outer periphery after the force load uniformly distributed along the circumferential direction is applied to the sealing ring. The said motion law is a composite...

Embodiment 3

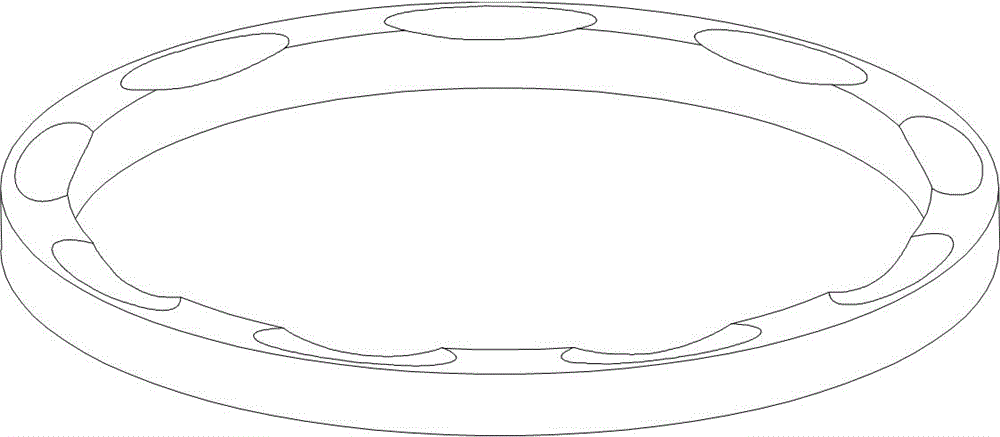

[0099] Example 3: Please refer to Figure 10 and Figure 11 .

[0100] The difference from Embodiment 1 lies in the shape of the shallow groove. In this embodiment, the shallow groove opens on the outer periphery of the sealing end surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com