Self-traveling submarine pipeline burying device and construction technique thereof

A self-propelled technology for submarine pipelines, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as pipeline damage, higher requirements for supporting mother ships, and lower burial efficiency, so as to improve development ditch efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

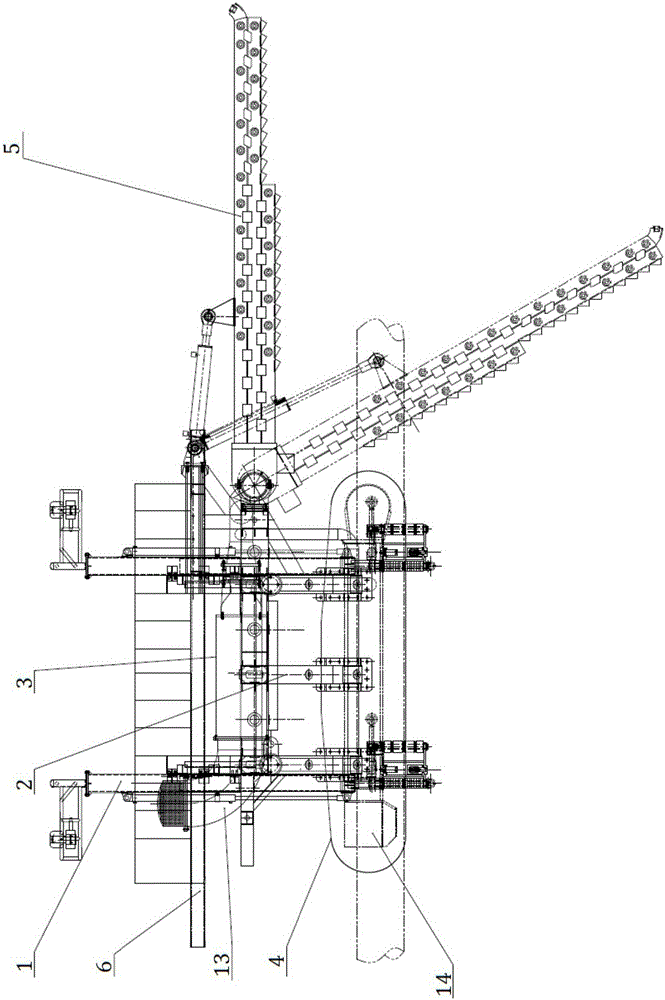

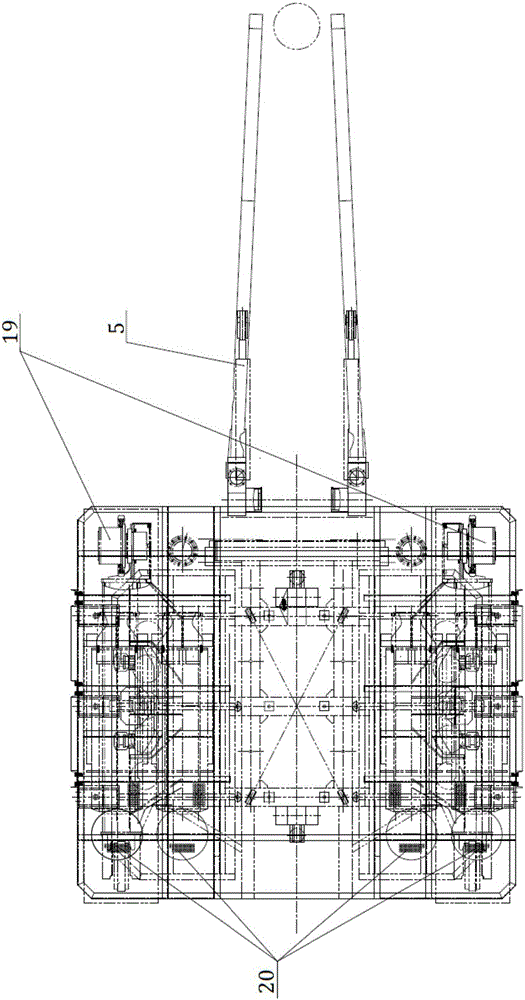

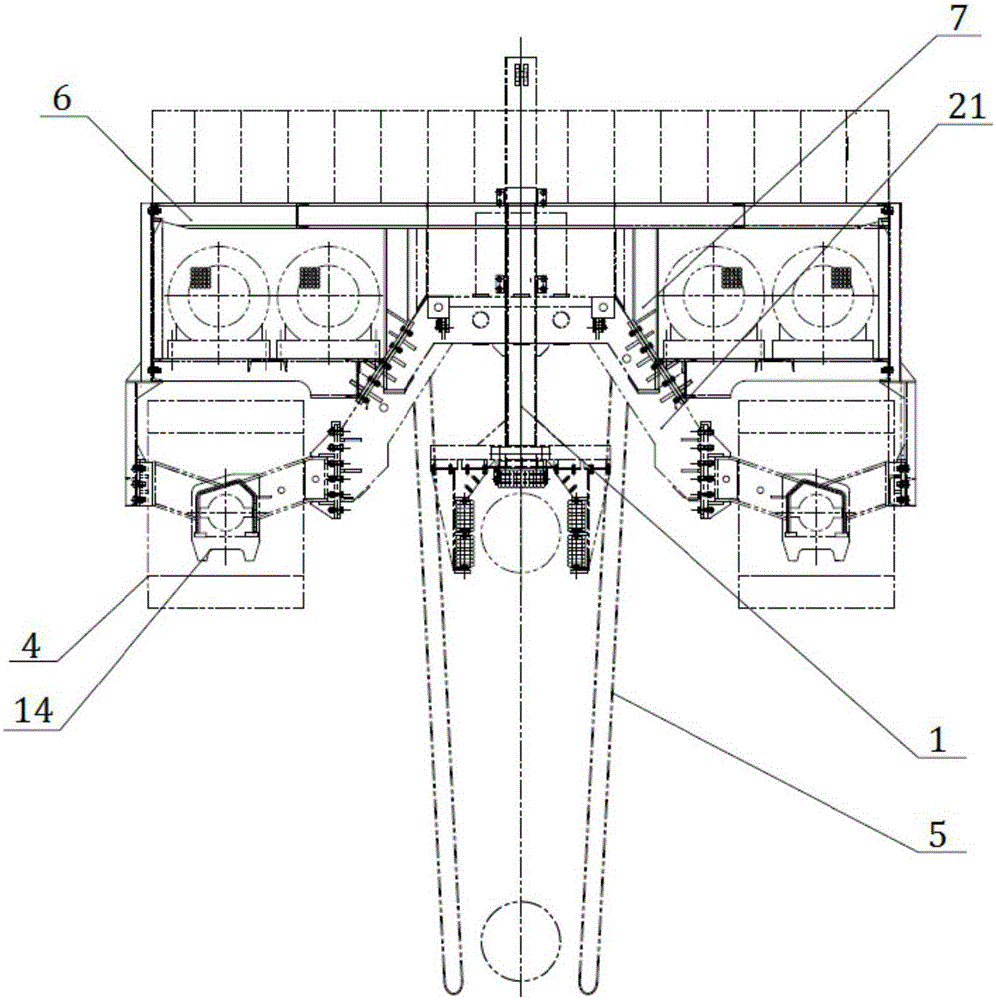

[0040] Such as figure 1 and figure 2 As shown, this embodiment includes: a hydraulic motor 19, a crawler running mechanism 4, a centering mechanism 1, a spraying and breaking soil mechanism 5, a main body mechanism 2 and a high-pressure flow-making mechanism 3, wherein: the crawler belt running mechanism 4 is arranged below the main body mechanism 2 On the left and right sides of the body mechanism 2, the centering mechanism 1 is perpendicular to the body mechanism 2 and is arranged in the center of the front end of the body mechanism 2;

[0041] Described track traveling mechanism 4 comprises: tensioning mechanism, track roller, drag chain wheel, drive wheel, guide wheel, crawler shoe, crawler chassis 14 and compensating mechanism 20, wherein: track roller, drag chain wheel, drive wheel The guide wheels are axially connected respectively, and are in contact with the track shoes; the track shoes, the tensioning mechanism and the compensation mechanism 20 are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com