An automatic grabbing device for concrete test blocks

A concrete test block, automatic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems such as the limitation of detection time for concrete compressive strength detection, the influence of detection efficiency and the accuracy of detection results, and the poor flexibility of detection time. The effect of restriction, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

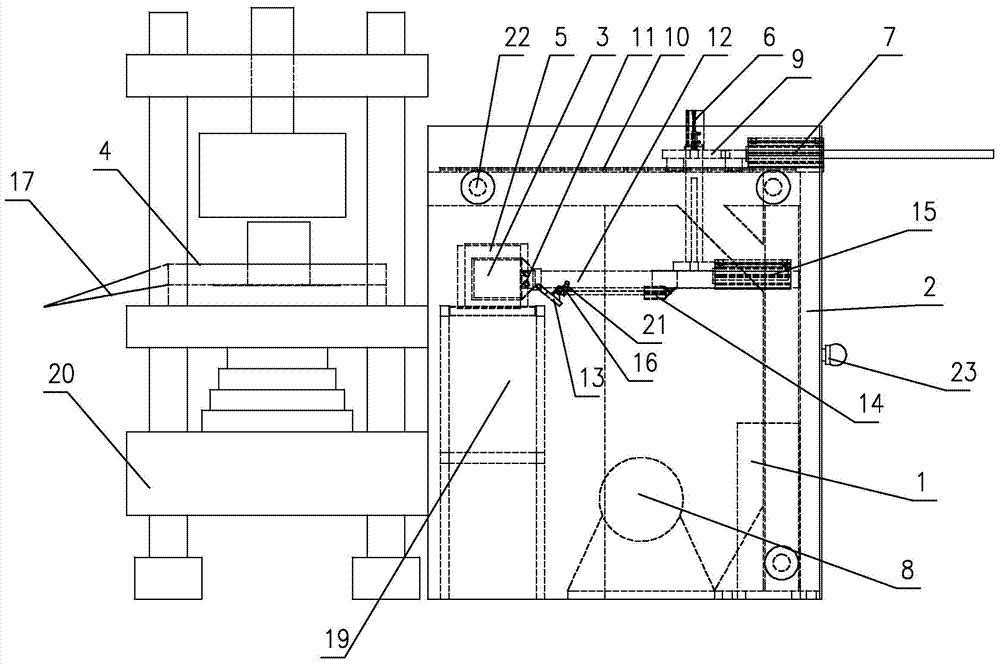

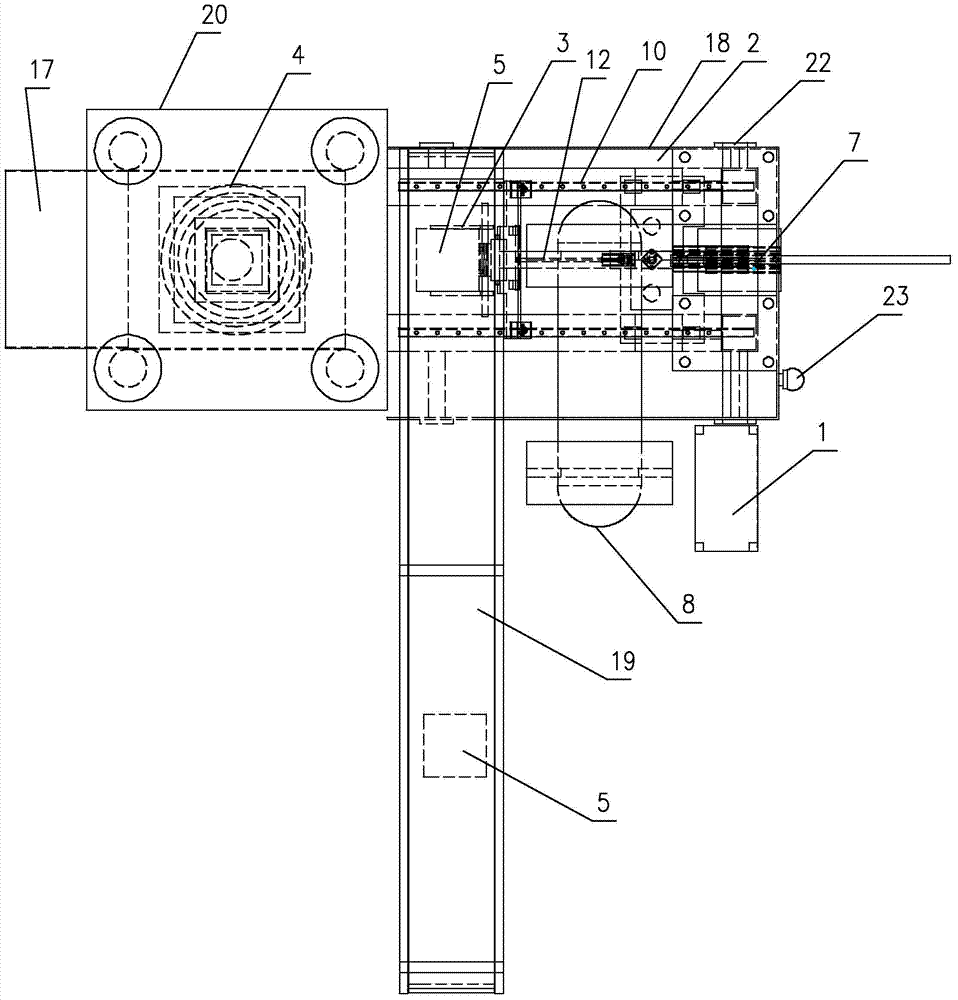

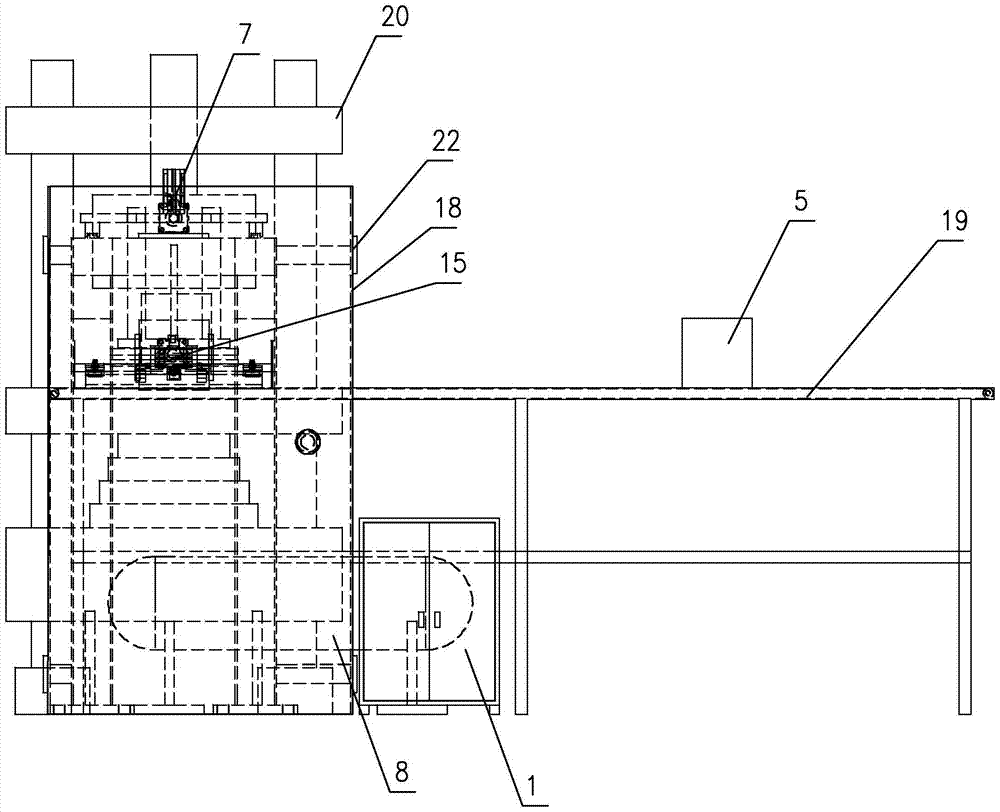

[0029] Such as Figure 1~3 As shown, it is a concrete test block automatic grabbing device of the present invention, which is suitable for the process of grabbing the concrete test block to the test platform during the concrete compressive strength detection process. The automatic grabbing device includes an electric control device 1, Frame 2, the drive mechanism installed on the frame 2, the fixture 3 and the cleaning device that can be driven by the drive mechanism to perform lifting and translational movements, and the electric control device controls the drive mechanism to drive the fixture down so that the fixture clamps the concrete test block 5 and moves to the pressure. On the test platform 4 of machine 20, unclamp concrete test block 5 and return to original position again.

[0030] In this embodiment, the drive mechanism includes a lifting cylinder 6 for driving the lifting of the clamp 3, a first pushing cylinder 7 for driving the translation of the clamp 3, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com